The Effect of Work Position on Picking, Assembly, Packing and Shipping

The economics of ergonomics for reducing stress

Work-related musculoskeletal disorders (WMSDs) are a common reported source of missed or restricted work in America. According to the Bureau of Labor Statistics, WMSDs account for over 33% of all worker compensation costs.

Ergonomic costs are staggering for industrial operations

The BLS quantifies this even more when it comes to actual cost impacts. Over-exertions that involve some external source were 23% of all WMSDs at a staggering cost of $13.7 billion a year. Other exertions or bodily reactions weighed in at 7.2% and $4.2 billion, while repetitive motions involving micro-tasks represent 2.6% of all worker compensation issues at a cost of $1.5 billion.

These costs can be broken into direct costs–workers’ comp, medical expenses and legal expenses–or indirect costs, which involve training, replacement, accident investigation, lost productivity, reduced morale and turnover. According to OSHA, an indirect costs range from a ratio of 4.5 to 1.1, depending on the amount of direct cost.

Safer operations tend to be more efficient and profitable

The Koop Index, named for former Surgeon General C. Everett Koop, tracks the performance of companies that win The C. Everett Koop National Health Award for outstanding worksite health promotion and improvement programs. The National Institutes for Health tracked the award winners for 14 years between 2000 and 2014, and found that their stock market appreciation was 325% during that period, handily beating the market average of 105%.

The ergonomic challenges of workstation design

We have extensively discussed general warehousing ergonomics and the ergonomics of various other work aspects. This article focuses on workstations, which were discussed in detail at Modex 2020 by Jeff Hoyle, Director of Ergonomic Services for North Carolina State University, and Robert Doucette of BOSTONtec, Inc.

The challenges:

- Optimize position

- Eliminate extreme movements

- Minimize forces and repetition

- Order & color coding

- Optimize lighting

Right: ergonomic workbench. Image credit: BostonTEC

Optimize position

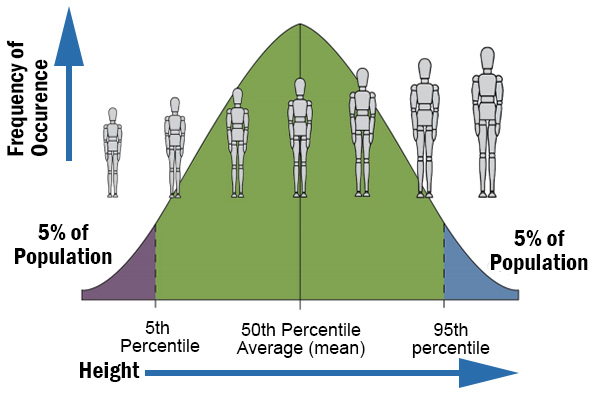

People are different, which means that for workstation design, the ergonomics will be different as well. One of the chief differences is height. While the majority of people fall into the green zone of average height, even within that group the variations can be important for ergonomics.

Adjustable height workstations

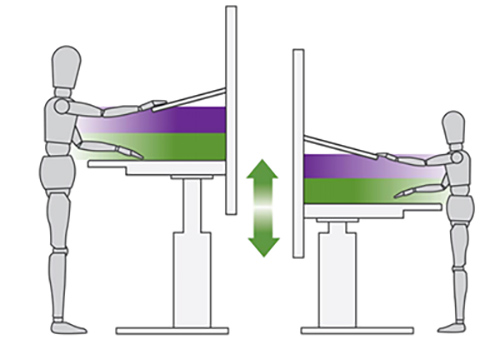

A workstation built to average will be difficult for someone much taller or much shorter than the mean. At times, this can’t be avoided, but in many cases, workstations can be specified for adjustable height. Height adjustability is useful not only for very tall or very short people, though. For specific tasks, the ability to adjust the bench top to the application may help workers of all sizes execute tasks more ergonomically.

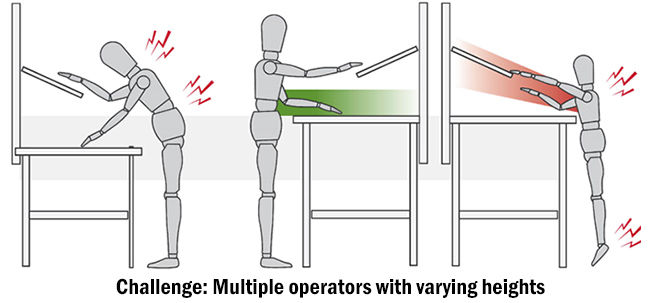

The illustration above is a multi-shift, multi-operator workstation. The worker in the middle is in a neutral position, where workstation’s height and reach spaces are optimal for them. When we look to the right, that person is shorter, and must make extended reaches, which stress lower legs and shoulders. The worker on the left is taller. If the workstation is built shorter, they must bend to work, which causes issues with their necks and lower back.

The goal of ergonomics is to create work spaces that accommodate the majority of workers in ways that reduce stresses and strains, whether they differ by height, reach capabilities, strength, flexibility or other factors

In this situation, the best option is to provide height-adjustable workstations that let operators set it to their preferences. The 6’6″ and 5’2″ worker can use the same station on different shifts without either person suffering from damaging muscular stress.

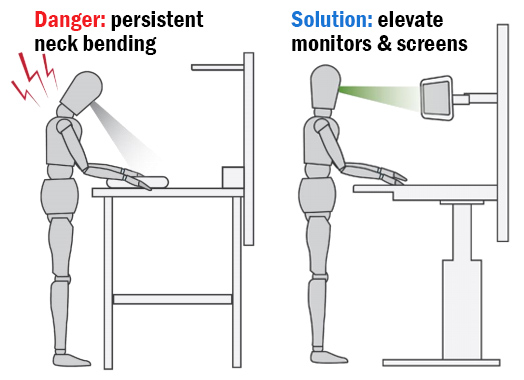

Reduce neck bending

Over time, persistently bent necks will cause injuries and disorders. Having documents or screens on the surface of a workstation causes the worker to look down day after day, year after year.

For operations where invoices, pick tickets, drawings or assembly instructions must be read by an operator, a simple solutions is a monitor arm or document holder that elevates the material to reading height. These solutions range from height-adjustable arms to articulating arms to keyboard trays. They’re economical and will speed task completions, aside from ergonomic benefits. Like height adjustability, these arms will work for people of various heights and sizes.

Final thoughts

The key to ergonomics is to make the environment fit the worker, not vice-versa. This can be accomplished many ways, ranging from facility design to equipment specification to process design. The next article in this series will focus on reducing extreme movements.

More resources

- How Conveyors Increase Warehouse Ergonomics

- Improving Warehouse Ergonomics

- Ergonomics and Hand Tools

Tags: workstations, ergonomics

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.