Ergonomics and Hand Tools

The stress of heavy hand tools and static positions can cause injuries, accidents, and musculoskeletal issues

Ergonomics should be wired into the design of all the processes of a modern industrial operation. Whether that means designing conveyor workstations with ergonomics in mind, utilizing work benches and stations that are adjustable for “right height” operations, adding turntables to rotate product, finding ways to reduce order pickers’ bending and stretching, or designing storage areas so that bending and stretching are minimized, well-designed operations bake ergonomics into their work processes.

One of the common areas you can attack is hand tool use. In many operations, strong younger workers may not complain about using heavy, hand-held tools for 8+ hours a day, but that stress is taking its tolls.

Tools, except for very heavy ones, aren’t always seen as ergonomic hazards. But they can be, and should be addressed.

Prolonged, everyday work on a production line with tools weighing just a few pounds can cause musculoskeletal issues (carpal tunnel, tendonitis, tennis elbow, bursitis and others) if ergonomics aren’t considered when the process is set up. These ergonomics issues are the silent killers of productivity and a great source of pain and expense. What can you do to reduce your risks?

Reduce static loads

“Static” loads refer to any process that puts people in the position of holding a “strained”, tense pose that can make them motionless. Static loads impose negative pressures on both muscles and joints, ligaments and tissues. This causes a reduction in blood flow, and dramatically increases fatigue, even in low-effort situations. In this regard, it’s worse than jobs with dynamic, or varied positions. This places workers who frequently find themselves in static positions at greater risk for fatigue, accidents, and potential injuries.

To reduce these issues, it is best to maintain a neutral posture. To do this, you must keep your body, leg, arms and hands in natural position. Workers who are executing jobs that require awkward posture are at risk for injuries and long term stress. They’re also markedly less productive and likely to file a worker’s comp claim. Hand tools in a production line are frequently the cause of static postures. Some ways to address this include making sure workers are able to adjust the height of their workstation and the reach they must make to execute tasks. Rotating jobs on a frequent basis also attacks this issues, provided the tasks are different enough in their physical demands.

Utilize a counter balance

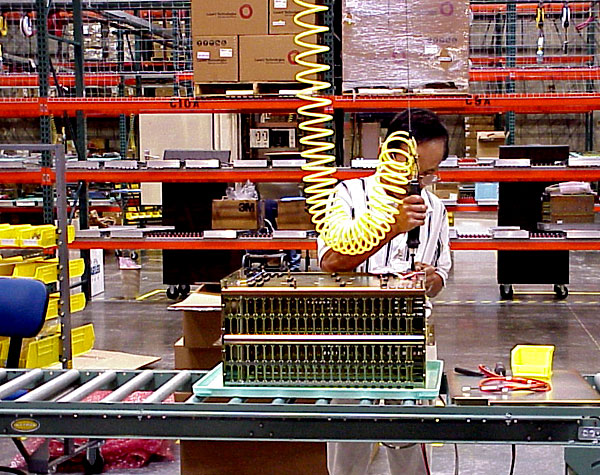

Air balancers and hoists are an effective way to reduce these stresses on people’s hands, wrists, and arms. These systems suspend the tool from a counter-balanced pulley and cable, allowing easy manipulation of the took without the weight and physical stress. Typically this equipment works best in stationary applications, but can be mounted to carts, workstations, overhead rails, and more on swinging arms and pulleys.

More information

- A guide to warehouse ergonomics (Cisco-Eagle)

- Ergonomic Guide to Hand & Power Tools (EHS Today)

- Understanding Hand Tool Ergonomics (Safety & Health)

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.