When a prospective client wants to visit your 3PL facility, it’s critical; you could be on the verge of new business.

You want to show them why they should select you as their 3PL of choice; that you’re the best choice; that you can be trusted to help them serve their clients. It’s no easy task running a successful warehouse or third party logistics company – it’s a multi-faceted organization with its own specific attributes and specialties.

Read the rest of this entry »

Tags: lean warehousing, warehouse, Third Party Logistics, warehouse flow, ecommerce, Warehouse Management, warehousing, Material Handling, 3PL

Posted in Warehousing & Distribution|

Working at height continues to rank high on the list every year when it comes to OSHA statistics, potential causes of major injuries and even fatalities.

Research shows that far too many people end up injured or worse because of their work on ladders, rooftops or other spots above the ground. As a result, it is extremely important for EHS leaders to be aware of the potential hazards their personnel face when working at heights, as well as the best ways to keep employees safe on the job.

Read the rest of this entry »

Tags: lean manufacturing, industrial safety, lean warehousing, warehouse safety, industrial accident prevention, Safety & Ergonomics, Warehouse Management, warehousing, Material Handling

Posted in Safety & Ergonomics|

Logistics pros are a lot like the offensive line on a football team: at their best, you know they are doing a great job, but their numbers never get called by television announcers. When they do talk line, it’s usually because someone committed a penalty or allowed a blitzing safety in for a sack. When the quarterback isn’t pressured and there are great running lanes, the line rarely gets mentioned. It’s kind of the same for 3PLs.

The goal of your 3PL should be to avoid those issues and remain unseen and unremarked on by end users.

Read the rest of this entry »

Tags: 3PL, lean warehousing, warehouse, warehouse productivity, Third Party Logistics, warehouse flow, Warehouse Management

Posted in Warehousing & Distribution|

Creating a lean warehouse or DC is not something a 3PL can accomplish overnight, but it’s something that can improve your efficiency, flexibility and ability to take on new business without expanding into new facilities or massively revamping existing ones.

It takes vision, planning, strategy, tools, foresight, patience and intelligent tactics. When your warehouse is lean, it will be easier to hold, inventory, and pull the most important goods. This helps you eliminate errors, increase throughput, and satisfy customers more comprehensively.

Read the rest of this entry »

Tags: 3PL, logistics, lean warehousing, Third Party Logistics

Posted in Warehousing & Distribution|

You know that your warehouse is critically important to being able to satisfy customers. You know how warehousing mistakes can impact your company’s bottom line, and how excellent warehousing can boost it. You know that a lack of resources can cripple a thriving storage or distribution operation. You also know that there are people in some organizations who don’t understand this.

Communicating the warehouse’s value is almost as important as establishing it.

Read the rest of this entry »

Tags: distribution centers, return on investment, ROI, Corporate Culture, lean warehousing

Posted in Warehousing & Distribution|

When it comes to warehousing operations, there are many ways to approach a continuous improvement project. You can automate, you can reorganize. You can employ a consultant. Three of the constant factors are time, standards, and data.

Here are some insights on each of these important areas:

Read the rest of this entry »

Tags: WMS, lean warehousing, ROI, wcs, benchmarking, data, facility optimization

Posted in Automation, Labor & Efficiency|

Small parts are more difficult to count, measure and handle. They tend to cause more errors than case picking or larger component orders. If you are having errors, you should try to define the causes — and the suspects abound. Can you find out what’s causing the errors? Once you do, what happens next? Here are some common causes and solutions to this issue.

Read the rest of this entry »

Tags: error reduction, lean warehousing, Order Picking & Fulfillment, 5S principles

Posted in Order Picking & Fulfillment|

One of America’s groundbreaking marketers, John Wanamaker, once famously said “half the money I spend on advertising is wasted; the trouble is I don’t know which half.”

Those who run warehouses, factories and other industrial facilities are hopefully not quite as in the dark about our expenses as Wanamaker was when it came to his ad budget, but there is definitely room for improvement when it comes to understanding hidden costs and fruitful expenditures.

For most of us, the coin of the warehouse is time and how it is expended.

Read the rest of this entry »

Tags: Warehouse Management, lean warehousing, distribution centers, time management

Posted in Warehousing & Distribution|

Studies indicate that order pickers spend too much time walking. Distribution center employees routinely spend more than half their day walking, not picking orders, packing orders, or replenishing stock. They’re going from point to point, burning man hours getting where they need to be, not working. And that’s the average — for really poorly designed operations, it’s worse.

As they tire, workers pick slower, pick less accurately, and work more dangerously — almost a zombie like situation! Every bad thing that can happen in a warehouse operation is amplified, the more time employees spend walking.

Check out our most recent Info-graphic, “Walking is the Walking Death of Order Picking Productivity” for more information on ways you can combat this issue.

More information:

Tags: ergonomics, order fulfillment, lean warehousing

Posted in Order Picking & Fulfillment|

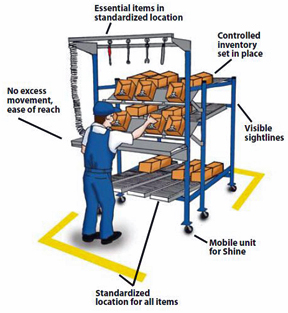

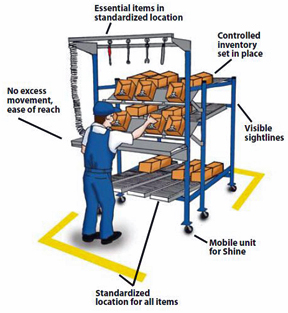

Based on 5 Japanese words that begin with “S,” the 5S Philosophy homes in on effective work place organization and standardized work procedures. When correctly implemented, it reduces waste and increases efficiency and overall work quality. You’ll also have a safer, more effective operation and employees who are more checked in than they were before. It simplifies work flow and helps you find inefficiency.

You may see things like empty flow racks, needless processes, over stocking, redundant operations, looming maintenance problems and more.

Read the rest of this entry »

Tags: lean manufacturing, lean warehousing, workstations, ergonomics, 5S workstations, quality, 5S principles

Posted in Storage, Organization & Workstations|

Read our customer reviews