How to Implement the 5S Approach in Workcells & Workstations

Apply sort, set in place, shine, standardize & sustain

Based on 5 Japanese words that begin with “S,” the 5S Philosophy homes in on effective work place organization and standardized work procedures. When correctly implemented, it reduces waste and increases efficiency and overall work quality. You’ll also have a safer, more effective operation and employees who are more checked in than they were before. It simplifies work flow and helps you find inefficiency.

You may see things like empty flow racks, needless processes, over stocking, redundant operations, looming maintenance problems and more.

1. Seiri – (Sort)

When you begin a 5S plan, you must know what is and isn’t working in the current workspace. During step one, you must sort, inspect and identify equipment, supplies and other items critical to the operation being performed. During this phase, you will remove everything from the work area. You will inspect & identify everything critical to functional success. You should eliminate duplicates, unnecessary equipment, underutilized items, trash and other things that aren’t required.

Once you have these non-essential items identified, classify them as (1) waste, or (2) valuable, but not critical. Dispose or store these items outside the work cell. When you sort these items, consider whether it’s essential, used occasionally or never used at all.

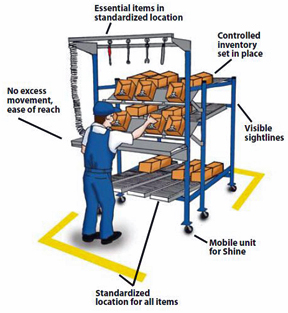

2. Seiton – (Set in Place)

Seiton is about “a place for everything, and everything in its place.”

Now that you’ve identified and sorted away the non-essential items, it is time to envision and organize. Take time to consider the flow of work through your station, and organize your equipment & supplies. Ask yourself:

- What do I need to do my job?

- Where should I locate it, once I’ve determined an item is needed?

- How many do I need?

Assign positions for everything you’ll need – storage equipment, machinery, supplies, raw materials. If there is something you always need, but always have to look for, make a specific place for it. Remember that you are envisioning your work area as it should be, with ease of identification, and proximity to work area as key factors. You’ll be maximizing your workstation layout so it works best for you. How can tweaking supplies or tool locations help you perform better in various situations?

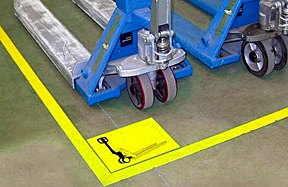

Eliminate “hunting” for tools or supplies in this phase. If people have to chase things like tape guns, brooms or packing supplies, create a specific place just for these things and keep them there. If that place is the floor, use striping to denote where the item belongs (like a pallet jack or a cart). If it is supplies needed for operation, consider modular shelving, dividable drawer cabinets or pegboards.

3. Seiso – (Shine)

Now that the clutter, unnecessary equipment and needless redundancy has been removed from the work area, it’s time to “shine” – more or less, to clean.

Some checklist items for this step include:

- Make sure the area has good lighting

- Clean the walls, floors, storage equipment and any production equipment

- Make sure that you can keep it clean over time

Cleaning isn’t really optional in a 5S implementation. It’s a daily, ongoing affair, and an important one. It isn’t something that is done only when there is time – it’s done without fail, every day. EXAMPLE: a work area is used to pack orders before they are shipped to customers. Excess packing materials should be cleaned and discarded. Boxes, cartons and filler material should be removed from the desktop. The floor should be swept.

Over time, these activities yield more than just a work area that’s nice to look at. When you work in a clean and organized space, you become tidier, more organized and better at your job. “Seiso” may help create a sense of pride and ownership. Beyond that, people may start to notice little problems before they become big problems. They may see pneumatic hoses with tiny leaks or oil gathering under a conveyor because they clean those areas. This may help you head off downtime and more expensive repairs.

4. Seiketsu – (Standardize)

Now that the first three 5S principles have been implemented, it is time to concentrate on best practices for the work cell.

Ideally, all the stakeholders should be involved, from the employees on the line to managers to those departments who receive work from the cell (internal customers such as maintenance or quality control departments).

The best people to define these standards are employees who deal with the issues on a daily basis

This helps make sure that everyone involved knows what they are supposed to do, what’s expected of them and what is needed to perform tasks. This helps you define what is supposed to be done in the previous three S’s. Update documentation of these standards and be sure everyone knows their importance.

In the example of an order picking area:

- The picker is in charge of a zone that includes rows of inventory stored on shelving.

- He has a conveyor and perhaps a flat work bench or other surface and a stop where a tote comes into his zone.

- Anything that isn’t needed to pick from his storage zone and place into the tote has been removed (Seiri).

- In the most logical possible way, he has placed all his needed equipment and supplies back into the work area (Seiton).

- He has cleaned the area, and he is keeping it clean – free of trash, his tools in correct places, his area of the floor clean (Seiso).

Now he has to do these things all the time.

Your operation has standards even if you do nothing. They may not be the standards you want.

5. Shitsuke – (Sustain)

Sustainable change is the hardest part of the process.

Like any other long-term endeavor, 5S won’t work if you don’t continue to execute. Shitsuke is the most difficult part of the process to implement. It means that when someone leaves, his or her replacement must be trained in the other four S’s. People tend to return to old habits unless new ones are instilled and actively managed. Once you’ve reorganized work areas, cleaned and created standards, the real work is in six months or a year – can you stick to them? Regular meetings, inspections and real emphasis all help.

It also involves adaptation to changing business dynamics. If your product mix changes, and this change flows down to work cells, you must recreate the 5S program to match the new business situation. It’s all about continuous improvement, and 5S is just the vehicle to get you there.

Resources:

- For great 5S information, check 5sbestpractices.com.

- Cisco-Eagle provides Unex Flow Cell workstations, highly configurable for lean and 5S redesigns.

- We also provide a high degree of custom workcell design, including workbenches, customized conveyor design, and much more.

Tags: lean manufacturing, lean warehousing, workstations, ergonomics, 5S workstations, quality, 5S principles

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.