Key Considerations for Warehouse Rack Aisle Widths

A balancing act: safety vs. storage density

Forklift aisle widths are typically set when pallet racking is installed. In many cases, such as narrow aisle projects, these spaces are critically important. Typically, warehouse managers don’t attempt to lay out these types of storage facilities. But for reach truck, selective rack applications, these aisle sizes are often “eye balled,” or given a 12′ width no matter what type of forklift is using the aisles. If you are laying out a facility, what criteria should you use for rack aisle width?

When laying out your warehouse out, you must balance conflicting goals

-

Narrower aisles that optimize space, allowing for more storage positions in the same space

-

Wider aisles that are safer and help forklift drivers maneuver, reducing collision risks

With forethought and the right equipment, you can balance these two goals. You’re generally dealing with two types of aisles:

Traditional counterbalance forklift aisles

The tried and true counterbalanced forklift needs about 12 feet to safely allow for picking and placing pallets. The forklift must have room within its turning radius to drive through, back up and access the rack on either side of the aisle. Many warehouses are laid out based on the traditional wide-aisle standard, and are set to 12 feet, whether or not that’s the optimum space. Newer forklift types can operate safely with narrower aisles.

Narrow aisle & very narrow aisle systems

Narrow aisle vehicles don’t require as much space as conventional lift trucks, which allows you to narrow your aisles to increase storage density without compromising safety. These systems rely heavily on the turning radius and maneuverability of the forklift.

General aisle configuration guidelines

Typical aisles for 3 or 4 wheel, counterbalance forklifts are wider than for other types of trucks. Here’s a simple rule of thumb calculation:

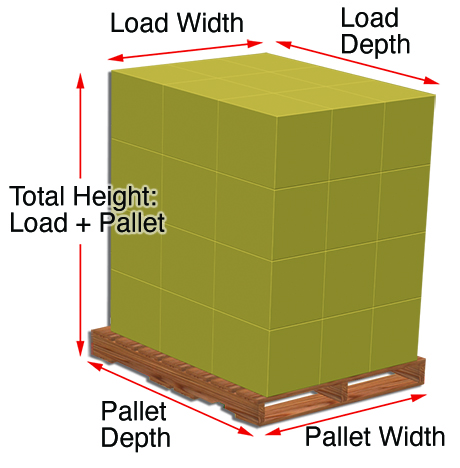

- Measure the head length: the distance from the back of the forklift to the front of the load back rest.

- Measure load length: the length of the pallet plus its load overhang.

- Add the head and load lengths together.

- Add at least 12” maneuvering space: remember to add a minimum 6” for pallet load overhang from the rack on each side of the aisle—or more if you typically need it. Wider aisles help drivers avoid backing into racks, but also consume space.

- Add all together for the minimum width for a typical counterbalanced forklift. Remember that this is only a guide and that most forklifts come with detailed aisle width specifications.

- Know your forklift turning radius to ensure drivers can easily access pallets without risk of striking racks.

Always consult your forklift documentation when making these determinations

These calculations work for standard forklifts in selective rack applications. For narrow or very narrow aisle racks, the forklift you’re using determines aisle widths. Many lift truck manufacturers have calculations designed for their vehicles. Also, for more complex rack design, consult us, or another qualified racking company for assistance.

Matching your rack, processes, layout and forklift makes your operation faster, safer and better optimized for space. Always install frame protectors to prevent damage in case of collisions.

Typical rack aisle width requirements for lifting equipment

Forklift types and rack aisle width

To fully understand whether or not you can narrow your aisles to save space, you should have a full grasp of the type of forklifts in use. If your aisles utilize more than one type of forklift, then the aisle must be wide enough to tolerate the maneuver of all machines in use.

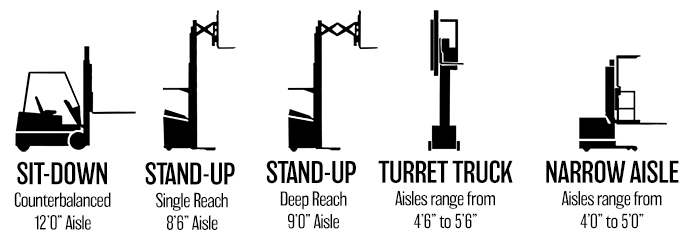

Sit-down counterbalanced

The most common forklift in the world. It needs plenty of operating space—at least 12 feet. Include the amount of space taken by column protectors or loads that extend beyond the beam on the floor or the first level of the rack.

Stand-up single-reach

These lifts can operate in even less space than deep reach models—as little as 8 feet due to shorter forks.

Stand-up deep-reach

Built for narrower aisle operations of 9 to 11 feet. The reach of the forks and the fact that operators require less space allow narrower aisles than for sit-down trucks.

Turret or swing-mast narrow aisle

Because the forks can pivot 90°, these lifts don’t turn to face rack aisles. Aisles can be less than 5’6”.

Narrow-aisle order picker

Use the least space—between 4 and 5 feet—since the operator usually walks behind the lift.

Pedestrian safety and forklift aisles

When people are present in forklift aisles, aisle width design is even more important. Transit aisles or 1-way aisles should have defined pedestrian lanes of no less than 3.3’ wide. For working/picking aisles, add the same 3.3’ pedestrian lane. Add more space to the load overhang to increase passage width since two sides of the aisle must be considered.

Tunnel lanes (underpasses) should not be used by both pedestrians and forklifts. Keep these passages separate as visibility and maneuvering space are even tighter than in picking and transit lanes.

Other rack configuration resources

Related articles

Download our Pallet Rack Guide

Pallet rack enhances your warehouse and improves overall facility performance when correctly specified, laid out and installed for the right load in the right positions. Check out our guide to specifications, styles, accessories and applications with expert tips from our employee-owners.

You’ll find quick, useful information on racks and how you can use them more effectively.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.