Can Warehouse Safety be Automated?

It's no secret - there is a near-epidemic of forklift accidents in the U.S., and lots of people are at risk

OSHA estimates 85 deaths, 35,000 serious injuries, and another 62,000 non-serious injuries. More than 11% of forklifts are involved in these accidents every year, meaning that the forklift in your warehouse is statistically destined to have an accident before it goes out of service.

Almost 40% of forklift-related accidents involve a pedestrian

And this doesn’t take into account the accidents that damage property, but don’t hurt people. Forklift-to-forklift collisions, or forklift colliding with warehouse racks aren’t included in these numbers if people aren’t injured.

OSHA emphasizes reducing injuries related to forklifts, AGVs and other powered industrial trucks. The main thrust of this effort involves training to help address what can only be called institutional ignorance of the handling characteristics, dangers, and poor processes regarding forklifts. It may not be enough.

There are ways to help increase awareness of both drivers and pedestrians to the presence of forklifts. When it comes to busy intersections, rack aisles, warehouse entry points, blind corners, narrow intersections, ramps, workcells, and other areas where workers and forklifts mingle, it’s inexpensive to place warehouse safety sensors that can help alert both the driver and the pedestrian that the other is close.

There are ways to help increase awareness of both drivers and pedestrians to the presence of forklifts. When it comes to busy intersections, rack aisles, warehouse entry points, blind corners, narrow intersections, ramps, workcells, and other areas where workers and forklifts mingle, it’s inexpensive to place warehouse safety sensors that can help alert both the driver and the pedestrian that the other is close.

The big takeaway: Automation doesn’t replace training; it augments and becomes part of it. Automated safety systems are about enhancing behavior, not replacing it.

Door safety sensors

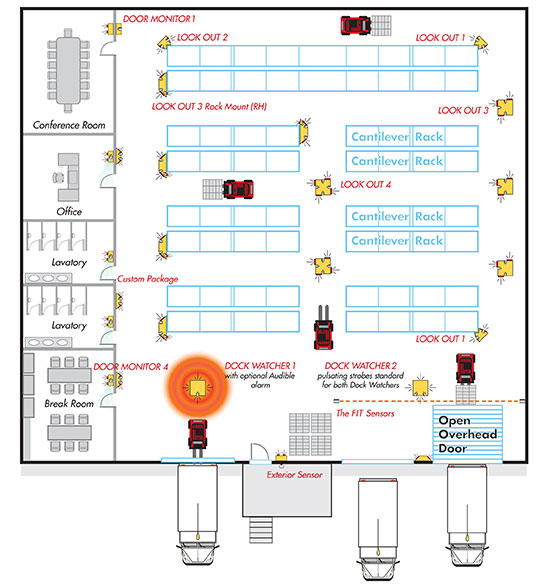

In the drawing above, you can see how these sensors can help in these “mingle” points. For offices, conference rooms, lavatories, and locker rooms, a simple door monitor sensor can alert the pedestrian that something is moving on the other side of the door. This is also good for overhead doors, where forklifts need to be aware that either a person or another vehicle is present on the other side.

Docks and shipping area motion detection

Docks and shipping area motion detection

But for dock and shipping doors, another type of sensor may be useful — the dock area safety sensor. The idea here is that, since docks produce an outside number of injuries and accidents, a motion detector suspended above a dock door can warn a forklift driver who is unloading a truck that a pedestrian may be in the zone outside when he backs up into the warehouse.

Conversely, it also alerts the pedestrians that a forklift is inside the trailer, and could re-enter the shipping/receiving area at any time.

These sensors are hung from the ceiling and monitor the zone where forklift/pedestrian accidents are most common — the staging areas directly behind dock doors. They have visual alerts, with flashing red lights, with the option to add audible alerts as well.

Automated motion alerts in rack aisles

One of the more difficult areas in a typical warehousing operation to maintain safety is the rack aisle or storage area. This is an area where order pickers, re-stockers, or other warehouse employees must work on the ground with moving forklifts. The narrower the aisle, the worse the visibility, and the less reaction time for both parties.

There are a number of warehouse collision sensors that can be placed as above, at corners where these kinds of accidents are more likely to occur.

Sensors cannot–and should not–replace training, traffic management planning, and good processes

Sensors become part of a smart training process, giving workers a better chance to avoid accidents. When you consider your alternatives, weigh your mixed zones–areas where forklifts and people must mingle–and look at places where a sensor deployment could help alert drivers, passengers or both. Visibility mirrors, barriers and other methods should be part of your overall strategy.

Tags: Automation, warehouse safety, forklift safety, sensors, collision avoidance

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.

Docks and shipping area motion detection

Docks and shipping area motion detection