What Is the 5S Process: 11 Visualizations That Explain It Best

Reduces waste, increases efficiency and overall quality

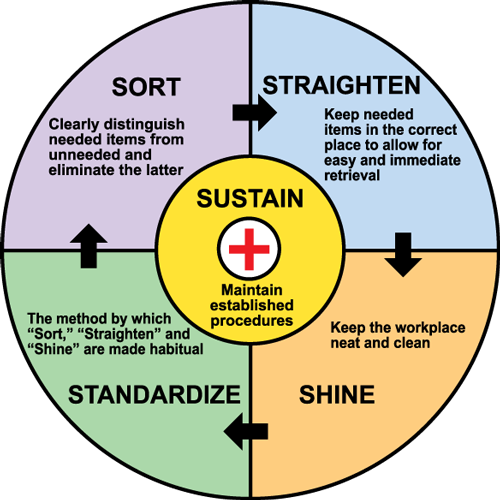

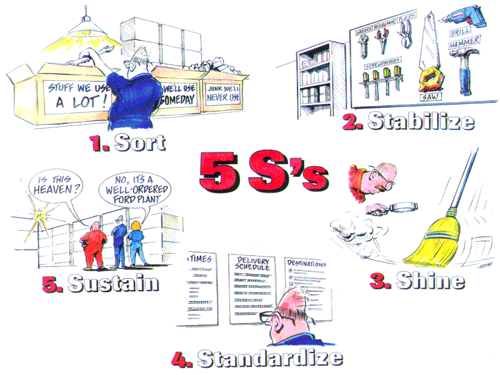

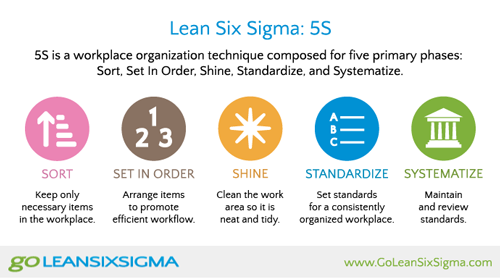

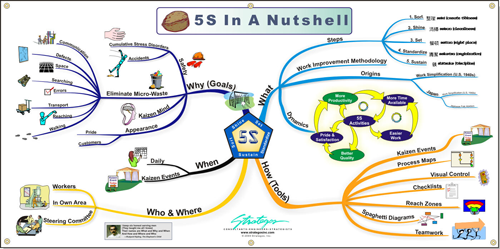

5S is a philosophy that hones in on effective workplace organization and standardized work procedures. The concept is based off 5 Japanese words that begin with “S”: seiri, seiton, seiso, seiketsu and shitsuke. When translated to English, there are five primary 5S phases: sorting, setting in order, systematic cleaning, standardizing and sustaining. Or in shortened terms: Sort, Straighten, Shine, Standardize and Sustain. When implemented correctly, 5S reduces waste and increases efficiency and overall work quality.

The 5S Philosophy is best captured in visualization, since its process can be complex, even if it is boiled down into five simple terms. Here are seven creative visualizations we found describing 5S, from organizations and vendors across the world wide web.

How to Implement 5S

Remember that “sustain” keeps it all together.

5S in the Office

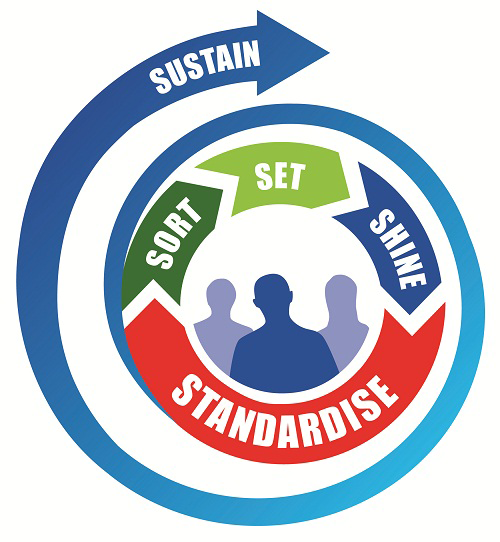

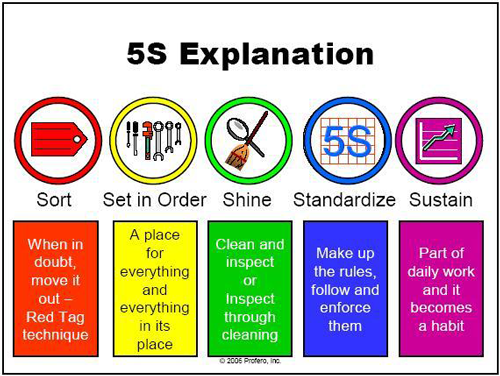

The graphic is circular in nature because the first four steps are ongoing and not a one time event. Sort, Straighten, Shine and Standardize are continually happening. Sustain is the glue that holds it all together. You have to sustain the other four steps in order to really be living 5S. Sustain is the piece that makes the other four habits.

5S Workplace Organization and Standardization

A Brief Overview of 5S

5S is a ways to improve workplace organization. It is a five-step process used to create a leaner and more efficient working environment. 5S can be done as a stand-alone effort or as part of a larger Lean initiative.

What Is 5S?

5S Explanation

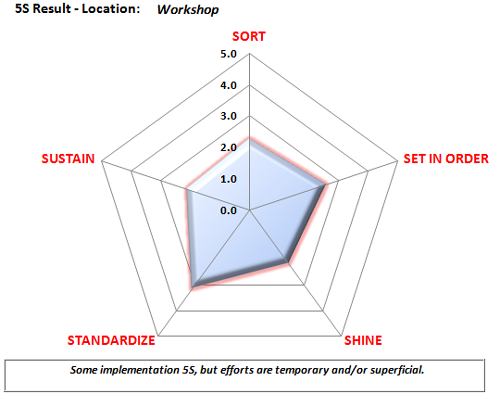

5S Audit Checklist

Final Thoughts

Did we miss your 5S graphic? If so, please add a comment below or send us a message on Twitter with your update.

Related Articles:

- The 5S Approach to Workcells & Workstations

- 13 Best Practice Tips for Warehouse Productivity

- Warehouse Ergonomics: A Quick Guide

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.