How to Create an Effective Incentive Program

The first step is defining excellent performance

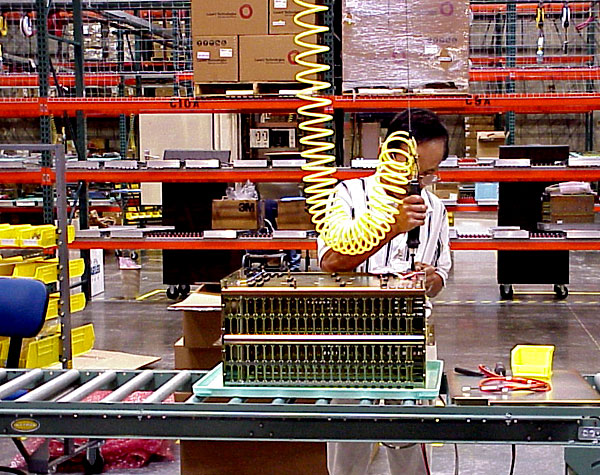

Incentive programs are surprisingly common for industrial operations, and they can produce significant savings, quality increases and improved employee satisfaction – if the program is built correctly. In manufacturing, assemblers are often incentivized for quality and speed. In warehousing, it can be reduced product damage, pick rates, error rates or any number of other categories. When companies build out these programs, there are opportunities to create great value. How are companies going about this?

Incentive pay is more common in industrial operations than ever

Some professions have been built on incentives: salespeople are almost always driven by monetary commissions. Tips, another form of incentives, drive most of the income for servers in restaurants and bars. A majority of workers are eligible for bonuses in most industries.

These systems tend to drive targeted behaviors: tips drive good service and top line revenue generation for salespeople. When it comes to warehousing and manufacturing, incentives are not nearly as common, but should they be? The difficult part is rooted in targeting profitable activities, measuring success and rewarding performance in a way that makes sense for both the company and employees.

What does a good incentive program look like?

Incentives work in warehousing, but you need to go into the process with open eyes.

Incentives must be balanced for difficulty

They must be attainable, but not by doing average work. Make the program too easy, and it’s really not an incentive program. But if it’s too difficult, people will dismiss it. Unattainable incentives kill morale. The high end of that measurement should generally be your target. If you have pickers who are 20% faster than the average worker, it’s okay if those people reach the incentive faster. You want them happy and fulfilled – working for you and not your competitors.

When it comes to incentives, finding the right balance between automatic and impossible is the goal. Workers should have to strive to get the incentive, but should be able to reach it consistently. Stretch goals, top rates and other benchmarks are good ideas.

Incentives must be balanced to avoid conflicting goals

If you create an incentive to reward lower error rates, a matrix should be created to ensure speed isn’t compromised beneath a certain level. It may be desirable that orders are picked slower to ensure an acceptable error rate, but your measurement system should take that into account. One category of work should not be sacrificed to improve another.

Incentives must be absolutely measurable

Create a metric for measuring success that can’t be gamed, bypassed or altered. The measurements should be tracked for targeted business results. Remember: everything hinges on good measurements.

Incentives must be fair

They shouldn’t create an advantage for one group to the detriment of another. It is very possible that the incentives created in picking can damage the shipping operation. Fair incentives take these inherent conflicts into account.

Read more: OSHA, Whistleblowers, and Safety Bonuses: Why You must proceed with caution when you incentivize safety

Incentives must be inclusive

Don’t design a system that rewards only part of your work force. Good bonus systems benefit everyone from receiving to processing to shipping. You’ll create dissension if one department has incentive opportunities while another is left out of the process. You can elect to create incentives for departments/teams, individuals, or both.

Whatever you do, everyone should believe that they are included and can earn something extra for better, smarter work.

Incentives should reward performers, encourage workers, and target non-performers

If your system is fair, high performing employees will reach it consistently. That’s okay – those are people you want to reward and retain. The “middle class” of workers will have to boost their game to hit that level, and those tend to be the best target for incentive programs; they are where the gains exist. Low performing workers may or may not ever reach the goal, but incentives help them understand the difference between their performance and desirable performance.

Incentives should be designed to help identify and promote better processes

Take the high performers I mentioned above. Are they better because they are doing things differently? Are they just harder workers? Good incentive programs help you understand why top performers are better. Your work force will pay attention to how the better performers are hitting their goals. You should encourage that. Have meetings and talk about the ways incentives can be met. Your people have invaluable insight, and incentives should highlight that.

Incentives should be benchmarked

Rewarding your people for gains is a good start, but what if you’re still lagging behind similar operations? Understanding where you are in relation to other companies like yours is critical to fair incentive programs that reward excellent workers and deliver results for your company.

Read more: How to Benchmark Your Warehouse

Incentives should reward both the employees and the company

Your metrics should be capable of defining the scope of savings or gains due to hitting your targets. Increasing throughput from, say, 175 orders shipped per day to 200 has a definable financial benefit. Good incentives reward employees for reaching that, but do not confer the entire amount. Given that there are always adjustments and miscalculations, you’ll need to hold back some percentage of the savings. This also makes the incentive program easier to sell to management.

Incentives should be flexible

Review yours frequently to ensure they continue to meet your goals. For instance, if a new order picking system (say a pick to light or voice directed system) is implemented, order picking speed and accuracy will change for the better. Your incentive programs might need adjustment to the new reality. They can also change if there is significant employee or management turnover, a change in process upstream, or simply a change in your market. Make it clear to employees that incentives are not necessarily forever, and are subject to change.

Incentives should be transparent, tracked and posted publicly

Perhaps transparent is too weak of a word. The metrics and results, to have maximum impact, should be publicly posted and advertised. Employees should be able to see who is hitting their rewards goals and who isn’t. This transparency helps create trust, but also eliminates misunderstandings and creates opportunities to coach employees if they are working hard, but simply not hitting their goals. It also creates competition, which can be a great thing if managed correctly.

Cash is king, but it’s not the only way

While bonuses, gain-sharing, and other methods are highly productive and very useful, you can also do things like granting privileges as part of your system. Consider things like good parking spaces, preferred shift choices, free lunches, parties, merchandise, extra vacation days and other methods.

Four Types of Warehouse Incentives

A number of tangible processes can be rewarded in an industrial operation. These may include:

- Throughput: number of orders picked in a period, or number of kits assembled. This could be by pieces shipped, dollar volume, or any other important metric in your operation. You can always break this down to a more granular level. For instance, in a shipping operation, orders picked per hour, orders per day, or other productivity measures can be utilized, broken down, and incentivized.

- Accuracy: error rates in terms of accuracy are always important. Find a balance between error rates and speed that delivers the optimum balance for your company.

- Returns: Returns are disproportionately expensive to deal with, so finding a way to reduce them almost always pays off. Return rates are not always tied to error rates, but there is a strong relationship.

- Safety: Days without an accident, safety knowledge, compliance with safe operations rules, and other metrics can be established to measure safety. It’s important to tie safety incentives to more than the simple metric of days without an accident, though. Since safety is inherently preventative, use your program to reward specific actions that can contribute to a no-accident record.

Almost anything that is both measurable and that affects your operational bottom line can be tied to incentives. One bonus of going through this is that you will be breaking down existing processes and metrics. Doing so helps you decide what’s truly important and how to address it.

More on industrial operations incentives:

- “Warehouse Labor Performance: And the Winner is…Everyone” (Inbound Logistics)

- “Cost-Driven Employee Incentive Programs” (Easy Metrics)

- “Starting a Warehouse Incentive Program” (Clean Link)

Tags: labor, ROI, industrial, Incentives, warehouse workers, bonus programs, personnel

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.