Tips for Tool Crib Security

Tools, dies, bits, and other materials in a maintenance or manufacturing operation are at risk for theft

In manufacturing, maintenance, and machine shop operations, tools, dies, and bits are among the most likely targets for pilferage. Tools fit the criteria for theft we discuss in our white paper, Reducing Warehouse & Dock Area Pilferage (PDF, 1.3MB, opens in a new tab): “items that are a combination of concealable, removable, available, valuable, or enjoyable are prime candidates for theft.” Items with a high perceived “value per ounce” are at risk. A $200 block that weighs 100 pounds is far less of a target than a $200 cutting tool.

Tools are in demand, easy to sell and expensive. Plus, many of the most expensive ones fit in a coat pocket, lunch box or tool box.

Who steals from their employers, and why?

Fraud experts claim there is a “10/10/80 rule” for employee theft:

- 10% of your employees will never steal

- 10% will steal when possible

- 80% can be motivated to steal — or motivated not to steal

For the 10% who are going to steal, the problem is solved only one way: by dismissal. You can’t worry about them, except to screen well when you’re hiring, and act quickly once a theft is detected. Dismissal is your only option. Protecting your tool crib should focus on removing access from that bulk of employees who aren’t inherently dishonest, but who will steal when the right combination of circumstances occurs.

A culture of fairness is your first weapon

In general, you want people to believe their employer is acting in good faith. Employees who believe they are getting a fair shake are far less likely to take expensive bits, cutters or other dies from a tool crib. Those who believe the company is their enemy are far more likely to steal. They’re motivated by things like financial pressures at home, personal debt, or other outside forces you can’t control. Under a combination of those pressures and an attitude that the company is uncaring or ruthless, they find motivation to steal. A culture of fairness is as important as a culture of security when it comes to plant security.

A culture of security is critical

- Communicate your security policies. People who understand that there are policies are less likely to steal

- Teach employees what to do when they see theft. Do they confront the thief? How do they report the incident? Do they take it to management? Plant security? Make sure they are protected for doing the right thing

- Consider a rewards system for reporting theft

- Conduct regular training and document processes for secure work, storage and tool handling

- Conduct regular inventory audits. You may not fully understand that there is shrinkage until it’s too late

- Work with your tool crib attendants to create a security policy that targets the most significant vulnerabilities and problems in the system

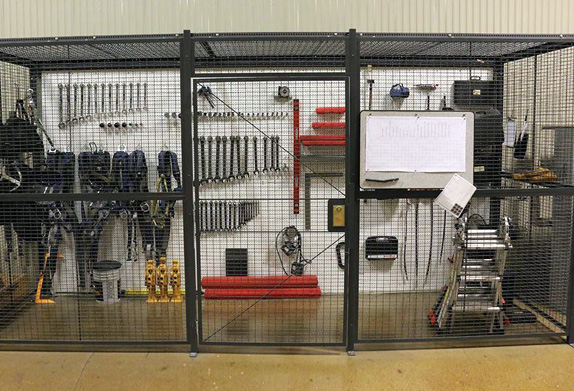

Access to tools and dies should be limited

The attitudes that drive people to steal must be dealt with, but you should also limit opportunities. People often steal when it’s perceived as easy, when they are presented the opportunity or when they believe risks are low. Reducing their opportunities will keep a great many people honest.

- Use lockable modular cabinets, tooling containers and other storage media

- Ensure employees lock their personal tool boxes

- Utilize wire security cages for expensive inventory/tools that must be protected

- Use tool/die vending machines

- Deploy camera systems and be sure employees know that you have them. Visibility mirrors are a good deterrent. You can also purchase “fake” cameras that lead people to believe an area is being monitored

Download our industrial security white paper

Tags: pilferage, machining, CNC, Tools

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.