Scissor Lift Table Loading Methods

How to load a lift the right way for longevity and safety

Scissor lift tables are a staple of many warehouses and factories because they are versatile and ergonomic. Anytime you need to raise and lower loads for processing, palletizing, depalletizing, picking or maintenance, lifts are a good option.

The way you load a lift is critical to its success and longevity. Since scissor lifts are extended on collapsible legs, weight and forces exerted on one side will stress the entire lift more than centered loads. A lot of the time, though, you are forced to load your lift unevenly. One key takeaway is that lifts have variable capacities based on the way they’re loaded and used.

When analyzing loading method, consider these factors:

- Friction and impact

- Horizontal impact against stops

- Incremental layers (each load increment is a percentage of both the total lifting capacity and the edge load rating)

- Load footprint relative to platform size

- The load’s center of gravity relative to minimum platform size

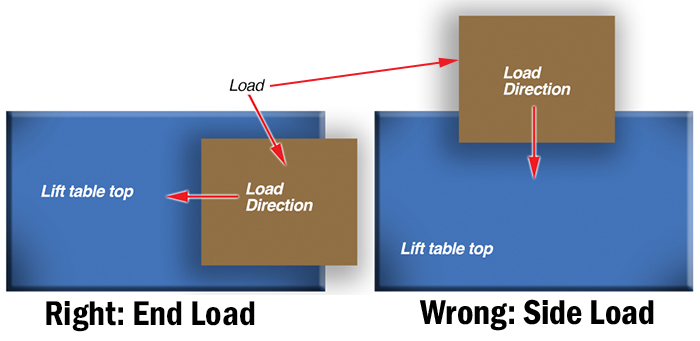

Side loading vs. end loading

Most scissor lifts are stronger over the ends than over the sides, which is why all lift manufacturers recommend end loading over side loading while the lift is extended to the up position. This creates less stress on opened legs and will preserve your lift longer.

Aside from the direction you load, the method is also critical.

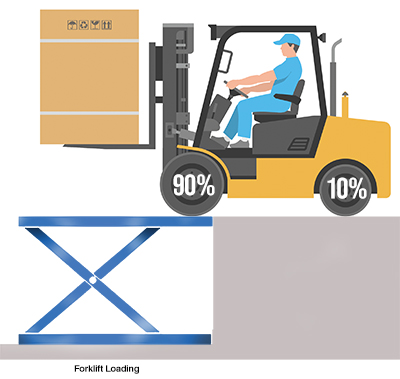

- Rolling loads (like driving a forklift onto a dock lift or a pallet jack from a platform to a scissor lift) will apply force and deflection pressure to only part of the leg structure. The force is usually temporary, as the rolling load moves to the centered position, but it must be accounted for.

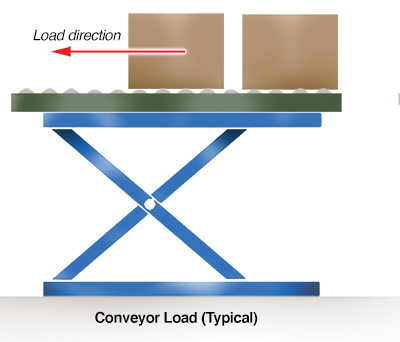

- Sliding loads are similar to rolling ones in that they usually occur in a single moment in time, and then are relieved as the load slides to the center of the platform. Examples include sheet metal feeding or conveyor mounted atop the lift.

- Placed loads (loads that are on/picked off by hand or by crane) exert more centered and even pressure than rolling or sliding ones.

Lift capacities are listed with each of these capacity types. Let’s look at that now.

Rolled on/rolled off: with a wheeled vehicle or cart

If you’re rolling a double-axle cart or pallet jack with an even load onto the lift, the load is split 50/50 as the first axle rolls onto the table top. A single axle load, like a large roll on a hand truck, places 100% of the load in one spot directly on the lift. A heavy and loaded forklift—as occurs in dock lift applications—radically splits the load, as much as 80 to 90% depending on the forklift’s counterweight. Rolled-on loads will challenge the lift and require careful consideration, but we deal in them frequently.

So long as we know in advance the weight of the vehicle, the maximum load and the way it will approach the lift, we can engineer a solution that handles the weight and point pressures.

Slide on/slide off: sheet feeding or conveyors

Sliding loads onto an open lift can put stress on the structure. These can be full loads directly onto a platform, full loads onto conveyor and partial loads (like sheets) onto either.

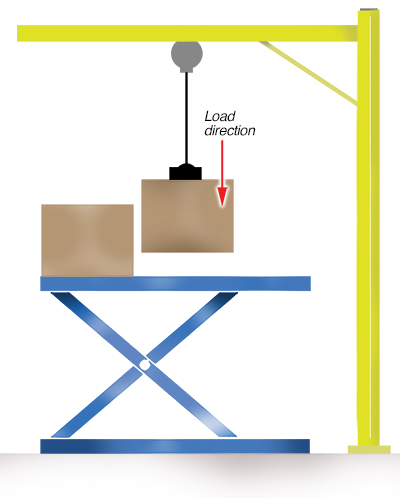

Placed on/picked off: stacking or crane loading

Some loading operations—like stacking layers of boxes by hand—impose little impact and no edge loading stress.

Some loading operations—like stacking layers of boxes by hand—impose little impact and no edge loading stress.

Vertical loading with a crane is no-edge loading, but may impact the lift if the load is placed roughly or with high velocity. For maximum capacity loads, lower the load at no more than 17 feet per second reduce platform impact. Speeds higher than that may damage cylinder packings, hoses or structure. The slower the rate of vertical impact, the better.

More information

This article is part of our guide to scissor lift tables. You can download that guide—and many others—from our literature section.

Other downloadable guides

These guides are PDF files and free to download:

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.