How Simulation Adds Value to Material Handling Systems Specification

The better your data, the better your simulation, the more certainty you have with your project

As we’ve discussed automating anything as complex as a large scale material handling process has risks, but there are ways understand the outcome better in advance and reduce any risks. It’s always good to have more data, and simulation plays into that scenario by giving you a view of what key systems, technology and process will interact in your system, with your loads.

Finding flaws and identifying bottlenecks

The most useful aspect of simulation is that it can highlight design flaws before you order equipment or pour concrete. While simulation can be costly and time-consuming, it can also be extraordinarily helpful. It’s kind of an insurance policy against a bad system design. It helps you root out inaccurate assumptions. The cost and effort are certainly worth it compared to the high costs of fixing problems after you’re implemented a solution and found that it can’t deliver.

The process of building data alone can be helpful, as it helps you gain deeper understanding both of your operation and the proposed solution. That data-gathering phase can often help you think through things that you may have missed.

When you simulate your system in advance, you’ll have more understanding of the outcomes.

Simulation benefits

- You can define the load, throughput, equipment and performance based on your best data and understanding.

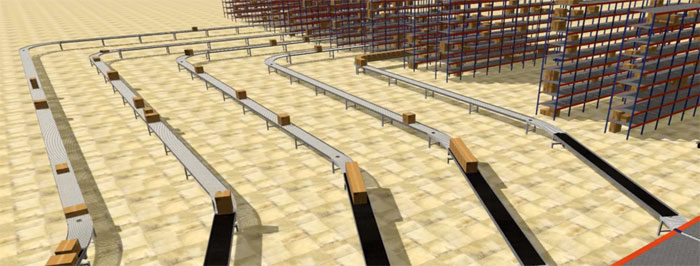

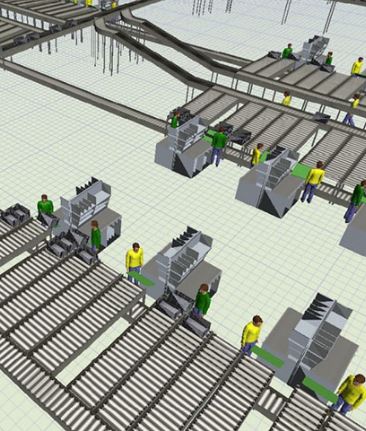

- You’ll get a 3D view of what the equipment looks like and how it might perform. This helps you visualize the operation and see where you may need to make changes or add resources.

- You can also use the simulation to help your colleagues and management understand what you’re trying to do, and how the investment will play out.

- You can define and simulate both the performance of the new equipment and that of your workers based on your data models. For instance, you could simulate pick rates before and after automation, which helps you justify the capital investment.

- You can plug scenarios in. For instance, you could simulate both a busy rush day or a slow day to understand the outcomes.

- You can identify bottlenecks and other inefficiencies.

- You can “game” scenarios, such as different picking methods, equipment, layouts, loads or other strategies. You can identify problems like replenishment rates and other issues.

- You can actively search for failure points and work to shore those areas up.

Simulation isn’t foolproof

If the data you’re using is incomplete, flawed or inadequate, the simulation won’t be useful. While simulation can help you sell the automation concept to your leadership, its main function is to help you build a better system with less guesswork. Be demanding when about the data and you’ll have the best possible look at what your new system will do once it’s live. Even with the best data, simulations can be off, but you’ll have much better information ahead of larger capital investments.

Who does the simulation?

You can request it from the equipment provider you’re using for the system – like Cisco-Eagle. We offer simulations. Like most others, we are going to provide you with an honest assessment of the system based on our perspective and knowledge. Many manufacturers and systems companies provide them. You can also choose an independent consultant with specific expertise to validate the design and assumptions if you want a completely different perspective that might give you an alternative point of view.

Whatever you decide, simulations are a good way to validate assumptions, identify problems and visualize your system in advance.

More information

- How to Calculate Automation ROI

- Case Study: Educational Development Corporation

- 13 Tips for Better Warehouse Performance

Tags: simulation, Factory Automation, ROI, data

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.