How to Calculate Automation ROI

What you should consider when justifying robotics, conveyors and other types of automation

Return-on-investment is critical to automation projects, but justification isn’t straightforward. If you’re trying to convince management to make capital improvements to your operation, a smart, accurate and succinct ROI summary can work wonders. Let’s dive into some methods you can use to understand what to do — and what you can’t quantify.

Most analysts agree that the fundamental reasons to automate are universal:

- Reduce labor costs

- Increase the overall efficiency of the operation, or critical points within

- To become safer and more ergonomic

- To cope with a shrinking labor pool

These are all true, but when you attempt to justify automation spending, you have to dig deeper, present more variables, understand all the costs and focus on real-world, tangible results rather than only simple projections.

Point #1: ROI is entirely dependent on good process

“The transformation can only be accomplished by man, not by hardware (computers, gadgets, automation, new machinery). A company can not buy its way into quality.” –W. Edwards Deming

Deming wasn’t talking about automation in particular, but when it comes to automation projects, he’s right. Your processes must be aligned with the automation to have any chance of success, and part of ROI is explaining how you’ll wed process to automated systems and equipment.

Automating poor processes makes them faster, not better

To automate your operation or any part of it, you must have full comprehension of the underlying human processes. You can’t implement high-value automation if the processes behind, around and near it aren’t working, are working against it or are ineffective for the next step. Companies that approach these projects from a data-driven, teamwork-oriented, fully-developed standpoint will have excellent automated outcomes that deliver fast ROI.

Point #2: Understand all costs

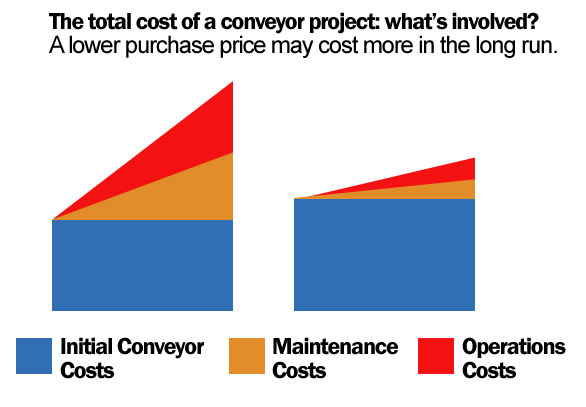

It should go without saying that the total cost of owning a conveyor system, robot or carousel is going to be more than the cost of that equipment.

Your initial costs for any type of automated equipment is higher than its purchase price. The exact ratio depends on the type of automation, and you can certainly lower it based on sound purchase decision, but it’s always going to be higher than the initial cost. If your robot, effector, software and vision systems cost $100,000, the cost of that system is not $100,000. Over its life, that robot will need power, maintenance, updates and more. It might break down at some point and need repairs (not to mention its lost productivity).

That isn’t to say that your formerly $100,000 robot that you should now think of as a $250,000-$300,000 robot can’t be a great investment. It absolutely can be, and usually is, or people wouldn’t be doing it. After all, it replaces expensive labor and allows you to operate faster and more often. Adding these ongoing cost factors into your ROI calculation will actually help you understand the true value better. If you are using ROI calculations to sell your management on the project, this may reduce ROI, but it’s more credible and won’t leave you in a lurch when it comes time to justify your results.

Well-executed automation delivers ROI that can account for operational costs, so you’ll still be able to justify the expenses.

A note on opportunity costs

Opportunity costs are “the loss of potential gain from other alternatives when one alternative is chosen.”

Your ROI case should discuss opportunity costs. A new sortation conveyor system will increase speed and reduce labor costs, but what else could be done with the money? If you are working to help management understand your needs in the warehouse, providing some examples of alternative investments will not hurt your case, and might help it. Some might be operational, like training programs or alternative proposals. Others may be completely outside your area of expertise, but you may be aware of gaps elsewhere the money could be used to fill.

You can’t always quantify those investments, but discussing them lets management know you considered the whole picture.

Point #3: Labor cost reductions are often the centerpiece

Automation, correctly applied, can reduce errors, increase throughput and increase safety, but it is frequently justified because it reduces the number of people required to achieve a task. Labor is typically the biggest operating expense for distribution, warehousing and manufacturing operations, so your justifications will always have to address labor cost reductions. The simple idea is that if you take the total cost of operating a system, total it, and then compare it to the average cost of the people it replaces, you’ll end up with a good idea of the ratio. But it isn’t that simple. To provide a comprehensive, valid justification, you should take all the factors into account.

A quick labor savings calculation

- The average U.S. warehousing employee earns $28,000 per year (according to Salary.com). Factor in benefits, and that cost escalates – call it $40,000 (you’ll know the actual costs for your company with some quick analysis).

- If the proposed automation costs $150,000 (including all relevant costs) the first year, and $37,500/year in ongoing costs, you have a projected annual, 3-year cost of $225,000 — about $75,000 a year.

- Labor costs in this scenario are $120,000 per year, per shift (automation almost always makes more sense for multi-shift operations). Over three years, doing the same work manually will cost $360,000 compared to $225,000 on a single-shift operation.

- This automation saves you $45,000 per year, per shift. Over three years, you’d save $135,000 per shift. It gets better assuming the automation doesn’t require repairs, reconfiguration or maintenance outside the annual costs you have already factored into it.

Caveats:

Don’t underestimate ongoing costs: Automation usually doesn’t eliminate all labor expenses. Technicians must maintain the automation, which should be about 25 or 30 percent of the total cost. That’s covered in the example above, but should be evaluated in your ROI calculations.

Don’t undersell reliability: When it’s working right, well-designed and in a fitting application, automation may outstrip simple labor costs. It takes no vacations and doesn’t need lunch breaks. It doesn’t require HR resources or as much management. It’s hard to express these advantages numerically without specific understanding, but it should result in productivity increases and reduced error rates. While automation will have downtime, breakdowns and technical issues, this tends to produce less total downtime than labor-driven processes in the right application.

The longer-term, the better: Organizations have varying standards for investments. Good automation will go more than 3 years in almost every instance, so savings continue to accumulate. You may have to sell your management on a shorter term, but you can usually support a longer one. Every year added reduces the annual cost of automation, while labor costs will escalate over that time frame.

Point #4: Ergonomics and safety should always be part of your case

According to the National Safety Council, a single medically-consulted injury costs over $39,000. Automation should reduce injuries and the potential for them, and that should be baked into your calculations.

Sometimes, it’s about reducing the risks of exposure to hazardous materials. In many other cases, automation can reduce the kind of tasks — such as palletizing heavy cartons — that result in stress injuries. Removing people from difficult, heavy labor and replacing that with a machine will always be a good investment. If you want to justify your system over three years, provide facts about the dangerous or stressful situations that the automation removes or reduces. Reducing EMR rates and worker compensation potential are fair numbers to discuss in your analysis.

Point #5: Labor is scarce and getting scarcer

That won’t change, at least not anytime soon.

According to Reliable Plant Magazine, U.S. manufacturers will face a need for 3.5 million jobs for the next ten years, and won’t be able to fill 2 million of them. Jobs like welders, truck drivers, warehouse workers, machinists, assembly workers, and others are hard to fill today and will be harder over time. This is partially due to the mass retirement of Baby Boomers in both high and low skill jobs. By 2030, older Americans will outnumber children for the first time in history, but the headaches for labor-dependent industries have already started and will get worse.

Today, 15.2% of Americans are 65+. By 2030, that swells to 23.5% – U.S. Census Bureau

An aging labor pool

Half the U.S. population is over 38 years old today according to the U.S. census bureau — a number that’s sure to grow over the next decade, meaning that labor-dependent industrial operations will find positions harder to fill for at least a decade. This is particularly true in major hubs like Dallas, California’s Inland Empire, Atlanta, Houston and Chicago. You’ll be competing for labor across the board.

While the effect of an aging U.S. workforce can be reduced to some degree by immigration, that can’t be counted on as a steady source of labor, due to both political considerations and improving economies in Latin America. It’s unlikely that immigration can make up the gap.

Manufacturing and distribution operations must cope with higher costs and a more fluid workforce. One way to do that is to reduce reliance on labor.

Automation helps reduce the impact of labor scarcity, and as you make your case for capital expenditures, higher labor costs are almost guaranteed. The easiest way to express this mathematically is to add percentage increases to labor costs in future years.

Factor in workforce flexibility

Automation and mechanization reduce reliance on employees’ physical capabilities. To heavy manufacturing or warehousing operations, a robot or lift system may mean that you can hire more types of people to execute the same jobs. Instead of relying on the strength of a healthy, younger worker, you may be able to extend the working life of older workers or hire women into positions that only strong men could execute before. This means that you can justify an upgrade by broadening the pool of available workers.

“Return on Investment (ROI) is a performance measure used to evaluate the efficiency of an investment or compare the efficiency of a number of different investments.” – Investopedia

Point #6: Various other costs

- Downtime and reduced capacity during implementation and startup

- Training and staff development to work with the new system. This may add more front-end costs

- Reduced management and human resources costs

- Elimination of extra shifts (huge if you can achieve it, which companies like Educational Development Corporation have done)

- Reclaimed space (or lost space, if the automation requires more than your manual solution)

- Scale. If your operation doesn’t employ enough people for labor reduction to be significant, you may need mechanization, rather than full automation. Small scale operations do automate, but the ROI case may be different

- Improved quality. Some automation initiatives are successful in increasing quality so much that they improve the output significantly. This means less quality control, fewer returns and less damage

Point #7: What are your competitors doing?

You can’t always keep up with the Joneses, but you should know what they’re doing — and how it might affect your company.

Part of a good ROI analysis includes where your industry is heading, what your competition is doing, and how you can ensure you are competitive with them. You may have direct knowledge of what they’re doing to be more efficient and effective. You may have to rely on published case studies or industry metrics. If you can find information that lets you know where things are moving, include it in your analysis. It’s always valid and persuasive.

Point #8: don’t oversell it

It’s always best to under-promise and over-deliver. When you’re working on ROI, that’s good advice. Take all the factors into consideration, and be sure to assign at least some weight to factors like safety, future workforce costs, accuracy improvements and ongoing cost of automation. You may face tough questions, but if you provide accurate numbers and realistic projections, you’ll be happier once the system is implemented.

Steps for justifying warehouse & material handling automation:

- Align your processes before you start any automation projects

- Understand and document all relevant costs for the current condition and the proposed solution, including opportunity costs

- Focus on labor, which tend to be the majority of warehouse costs

- Be sure to factor in safety and ergonomic improvements.

- Remember that labor costs are going to climb, and that available workers will be scarcer in the coming years

- Document all related costs (downtime, training, reduced HR, shift reductions, reclaimed space, etc.) to both the current condition and the proposed solution

- Understand as much as possible about how your competitors and peers are executing the same tasks you do

- Don’t oversell the process; be pragmatic and factual

More reading

- Robotics ROI Calculation – Machine Design

- Train Order Pickers Like Work Like Fast Food Workers – Cisco-Eagle

- Warehousing and Tight Labor Markets – Cisco-Eagle

Tags: Robotics, Automation, labor, ROI

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.