Bowing, Leaning and Out-of-Square Pallet Racks: Causes & Solutions

How to identify and resolve damaged rack issues

Racks will often be damaged over a long lifetime of use. When you see a bent beam, out-of-square beam, damaged upright or other issues with your pallet racks, you can’t ignore it.

Prevention is critical

Issues of bent beams or bowed uprights may well mean that you need to replace the entire rack structure or significant components of it. But you can often prevent this kind of damage by ensuring your racks are correctly specified, installed, loaded and used. What are some of the most common causes of rack damage?

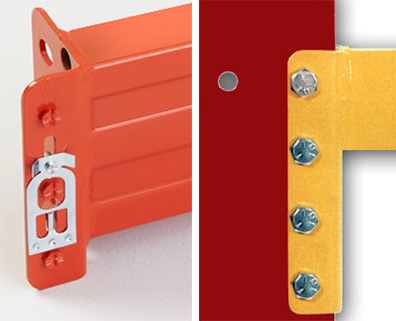

Inadequate or weak beam connections

Above–more is better: Beam connections are critical for fall and damage prevention. More connections are safer and more rigid. Look for teardrop racks with 3-rivet connections and safety clips. Bolt-on beams should be drilled for 3+ bolts so you can add more bolts to strengthen the connection and structural rigidity. Adding these connections increases installation time, but strengthens the beam for everyday use.

Poor beam connections can cause racks to warp, bow and fail

- The more connectors (pins, bolts) the better and tighter the beam is. This can also increase beam capacity and better impact resistance.

- Bolts tend to be tighter than pins, but are harder and more time-consuming to install.

- If you’re operating in a seismic zone, the engineering standards are more stringent.

- Use the proper connectors, as specified by your rack manufacturer. Sizes, standards and types should match.

- Inspect for missing bolts or clips or pins. Always replace them when found.

Poor beam connections make your rack less stable and more likely to sustain operational damage. Over-engineer your connections by adding more bolts, rivets or pins for the safest possible operation.

Upright damage and warping

Racks that lean or bow outside tolerance aren’t safe because they can no longer bear the capacity they were designed to hold. This reduced capacity makes a dangerous collapse much likelier, meaning that your people and inventory are at risk. The RMI (Rack Manufacturer’s Institute) has created standards.

The out-of-plumb ratio: is the upright leaning?

This is the maximum horizontal distance from the column’s centerline at the floor in inches from the top beam level divided by the vertical distance in feet from floor to top beam level. If you can obviously see an upright leaning, it should be addressed immediately.

The out-of-straight ratio: does the upright bow?

This is the maximum horizontal distance in inches from the centerline at any point on the column to the plumb line from any other point on the column divided by the vertical distance in feet between those two points.

The worse these ratios, the more likely a failure. ANSI MH16.1-2012 sets the tolerance level at 0.05 inches per 12 inches height. That’s 1/240 for either the plumb or straight ratio. If your rack columns either lean or bow, they always warrant careful evaluation–even if they’re within tolerance.

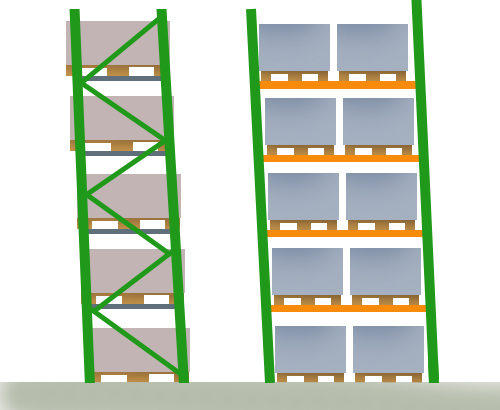

Above, left: a pallet rack leaning backwards. Right: a lateral lean. Leaning racks put stress on the beams as they cannot adequately connect to uprights. This can cause a dislodged beam and a partial or full rack collapse.

What causes pallet racks to bow or lean?

- Overloading your beams—or loading them incorrectly. Make sure your loads are square, uniform, evenly distributed and designed for your rack system.

- Forklifts striking the racks. This typically happens at the base, where a backing forklift can easily hit a leg, but can also happen when loading the rack at upper levels.

- Changing your beam level elevations. As covered here, any change to beam elevations can dramatically alter the rack’s capacity. This is a pretty common issue with racks and changing layouts, so it’s important to understand the impact of it.

- Beam-to-upright connection problems: Inadequate connections can stress uprights. Be sure your beams are secure and all safety clips used. Were safety clips engaged? If it was bolted, were the right bolts used and installed tightly?

- Installation errors. Was the rack installed straight, or shimmed when it was not level? Was it adequately bolted to the floor, with the right anchors?

The dogleg

If the rack is out-of-plumb at the base (anywhere beneath 5 feet) it’s referred to as a dogleg and was probably the result of a forklift impact. You should address that upright immediately, as it ignores out-of-plumb ratios and is considered dangerous every time. Install column protectors to protect your investment from a collision. Even the best drivers will strike racks over time, so it’s always justifiable.

Read more: Pallet Rack Inspection Fundamentals

Why is the rack out of square?

Radical bowing at a particular point–even within tolerance–is a red flag. Why is that particular area bowed? Was the beam loaded incorrectly? It’s best to understand why the upright is bowing when you see it. Unless you understand what’s causing the rack to bow, replacing it may not solve the problem at all.

Loading patterns

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.