A Guide to Shoe Sorter Applications

For gentle, medium-to-high speed product diverting, sliding shoe sort conveyors can be ideal

Conveyor systems with shoe sorters are the go-to method for carton or parcel handling divert applications, but aren’t limited to just those types of loads. Shoe sorters are gentle with the product, fast and reliable with lower maintenance than other sortation options. What are the best applications for shoe sorter conveyors?

Shoe sorters convey the product on slats (usually aluminum) that are perpendicular to the flow direction. Plastic or poly wedges called shoes ride on the slats as they drive conveyed product forward. When the product reaches a divert point, the system activates and the shoes glide smoothly along the slats to softly push the load to the correct lane.

A blend of medium-to-high sort speeds, highly accurate, gentle sortation: factors for consideration

Item fragility: Since the shoes gently push the load against a low-friction anodized aluminum slats, you can sort relatively fragile loads with them. Shoe sorters are very gentle with products because of this diverting method.

Load types: Shoe sorters are mostly used in carton/box applications, but can convey other products, including envelopes, crates, totes and some types of bags. Shoe sorters may not be ideal for all types of loads, but they’re versatile enough to meet many needs outside their traditional case handling role. If the load’s bottom might scar or stick to the slats as it slides across them, rough exteriors may not be ideal. Specific shoe sorters also have dimensional minimums you need to observe.

Flexibility: Within their range of applications, shoe sorters are extremely flexible, both in load profiles and divert methods. They handle a large variety of order sizes and load types. They can be used throughout most distribution centers in packing, work-in-process, shipping and other areas.

Accuracy: Shoe sorters are one of the most accurate sortation methods.

Speed: Cross-belt, Bombay sorters, tilt tray systems and sorting technologies can be faster at the high end of sort speeds, while shoe sorters offer a medium-to-high sort rate range (up to 300 cartons per minute). Shoe sorters are a very fast sorting method that serve most parcel sort operations, but not the fastest available.

Costs: Shoe sorters are a middle-range sortation solution, falling between the more expensive options (loop or Bombay sorters) but costlier than narrow belt and some pop-up methods. Like any sort method, the primary cost is generated by the number of sort points in the system.

Their place in the system: Because shoe sorters don’t exist in a void, their induction conveyors, management systems and accumulation and gapping processes all factor into the solution. If you can’t feed the sorter fast enough, its speed becomes irrelevant. A good rule of thumb is that your induction systems should be able to match or exceed the sorter’s capacity. Then consider what happens once the load is diverted. Will you need to re-circulate loads, or can the system process them entirely?

Shoe sortation conveyor specs

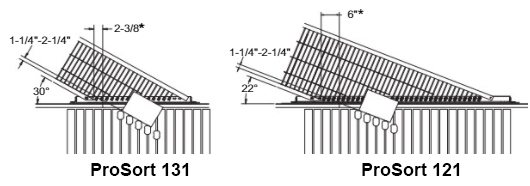

ProSort 121 & 131

These models provide single-sided sortation for small, fragile items at 22- and 30-degree angles and high speeds. Speeds up to 450 FPM (121) or 350 FPM (131). Maximum product weight is 50 pounds. Conveying surface widths: 15″, 21″, 27″ and 33″.

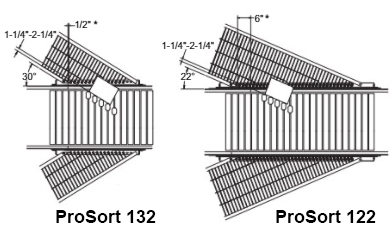

ProSort 122 & 132

In contrast to the previous two models, ProSort 132 and 122 offer dual-sided sortation, but they provide the same speed advantages and ability to handle small, fragile products with 22- and 30-degree angle sortation. Speeds up to 450 FPM (122) or 350 FPM (132). Your package must be a minimum of 4.5″ long and weigh no more than 50 pounds. Conveying surface widths of 15″, 21″, 27″ and 33″.

Read more: ProSort Series 100

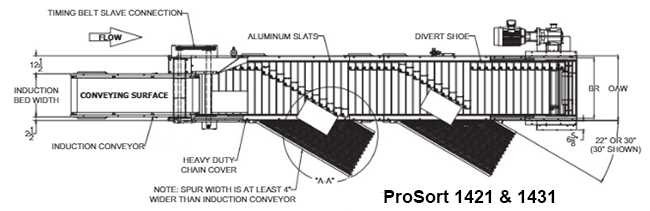

ProSort 1421 & 1431

Extremely fast (up to 600 FPM for 1421 and 350 FPM for 1431) and ideal when close divert centers aren’t critical with maximum product weights up to 100 pounds. Induction bed width range of 18″, 24″, 30″, 36″ and 42″. Package minimums are 9″ x 4″.

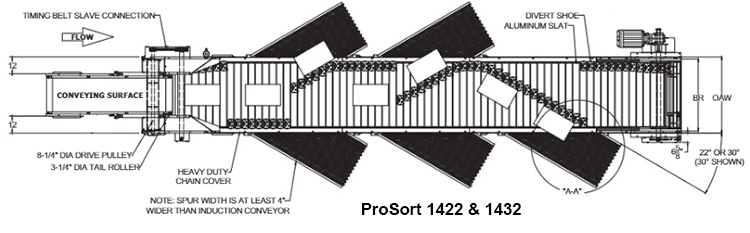

ProSort 1422 & 1432

Another high-speed option for gentle, 22- or 30-degree diverting for packages as small as 9″ long and 4″ wide, this time with dual-sided sortation rather than single. Speed: up to 600 FPM (1422) and 350 FPM (1432). Maximum load weight is 50 pounds per foot. Models 1422 & 1432 offer the same 18″ to 42″ width range as 1421 & 1431.

Read more: ProSort Series 1400

Consider the future; understand the present

Just as you would for any project, consider needs today, tomorrow and down the line. Integrate future expansion plans, market shifts and other external factors as much as possible as you move forward. Your operational objectives are always the guiding “true north” of the project. Shoe sorters are just one sortation option; consider what other technology might do the job better. Ask yourself what the core issues are when you must sort items. Always profile all of your loads–and potential loads–based on dimensions, weights and characteristics. How fast do you need to sort and at how many points? Have a thorough understanding of destinations and downstream processes.

It’s a lot to consider, and of course, Cisco-Eagle’s employee-owners are always available to assist you with an in-depth analysis of your needs.

Tags: Automation, sortation

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.