Security Cages and Partitions: Choosing the Right Wall Type

Woven vs. wire vs. solid partitions

Above: wire security cage installed beneath a mezzanine using both wire mesh and solid sides

Wire security partitions are a great way to make your warehouse more secure. They’re used in tool cribs, for high-value inventory and to control access to restricted areas. You can specify a partition of almost any shape, almost any size and with a world of locks, windows and other options to create a versatile, secure storage area. You can also specify the wall type: woven wire, welded wire and solid. What wall type should you use?

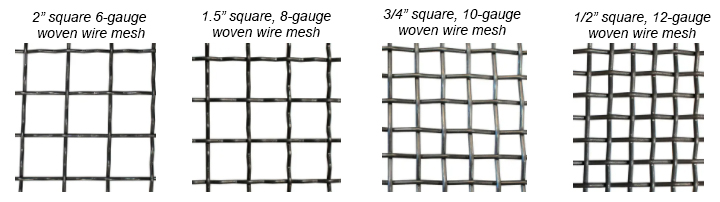

Woven wire

Woven wire has been a longtime standard in the warehousing industry due to its strength and versatility. Various gauges of wire are woven together in a crimped pattern. When wires cross, the entire wall section becomes extremely strong and rigid within a panel system.

Woven wire’s chief advantage is the versatility that allows it to fit almost any security standard. For instance, some higher security installations require that nothing larger than a dime can pass between the mesh, so the ability to deploy very tight mesh patterns comes into play. The lower the gauge number, the thicker and stronger the wire.

- 2″ x 2″, 6-gauge woven wire is the strongest and most secure option for the most secure installations.

- 1-1/2″ x 1-1/2″, 8-gauge woven wire provides smaller openings when needed. It’s not as heavy as 6-gauge, but is still an extremely strong alternative. It’s specified at times as a more secure alternative to chain link fencing for indoor applications.

- 3/4″ x 3/4″, 10-gauge woven wire is often used in pharmaceutical and medical applications because the mesh is tight enough to block pill bottles from passing through the partition. This style is frequently used for server and colocation facilities. Anywhere you have a relatively small, valuable item that cannot pass this mesh is a great place to specify this size.

- 1/2″ x 1/2″, 12-gauge woven wire offers the tightest mesh option for applications that require the least possible passage of materials through the partition. If coins or tiny parts are a security concern, this size will prevent all but the tiniest items to pass through. This wire configuration is sometimes used for machine guarding because its small openings help safeguard against parts flying away from machining devices or robots outside the guarded area.

Read more: Welded vs. Woven – a comparison matrix

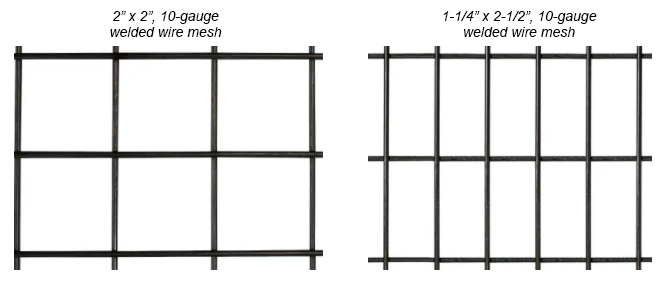

Welded wire

Because welded wire partitions are welded at every intersection, it eliminates the crimp used by woven wire cages. This makes welded partitions lighter and uses less wire than woven alternatives. More importantly, because the partition’s rigidity isn’t dependent on the weave, it can be cut without losing its shape. This may allow you to add windows, pass-throughs or other modifications after the cage is installed.

- 2″ x 2″, 10-gauge square welded wire mesh is general-purpose for warehouse and industrial applications, lockers and secure storage. It’s affordable and strong. It’s also used for pallet rack backing systems.

- 1-1/4″ x 2-1/2″, 10-gauge rectangular mesh tends to be used for machine guards and other products. This mesh meets ANSI/RIA R15.6-1999 standards for robotic machine guards. It can be used for partitions and cages, but is generally not specified for those applications.

Why wire vs. solid?

Wire cages are specified in preference to solid ones because they allow both visibility and air flow. This allows you to take advantage of facility climate, ventilation and lighting. Because you can see inside, you can also monitor inventory and other factors inside the cage.

Solid walls

Left: steel partition wall for solid, opaque protection. Right: transparent poly panel partition for visibility into the protected area.

Companies use wire mesh most of the time because it’s both functional and economical, but you may need to restrict visibility or completely enclose an area without new construction. That’s where the solid panel alternatives come into play.

- Solid steel partitions: 16-gauge sheet metal can serve as a security partition, and has some advantages. First, onlookers cannot see what’s behind the panels, which some security applications demand. There is no way to pass anything through a solid panel. You can restrict access with the same array of locking systems available to wire mesh partitions. Also, you can paint the panels most any color for aesthetic appeal.

- Transparent polycarbonate partitions: These 1/4″ polycarbonate panels offer the same protection for item pass-through as solid steel, but allow visibility. Polycarbonate is frequently used for social distancing applications, but can also be installed for security.

- Expanded metal partitions: These aren’t solid, but offer some of the tightest opening spaces available to restrict pass-through.

It all comes down to access control

All of these alternatives have the same mission: to control access to a restricted area. Decide your partition type based on your needs:

- How strong should the panels be? The stronger the panel, the smaller the openings.

- How much concern is there for item pass-through? Are there small, valuable items you need to restrict?

- Is visibility critically important? The tighter the mesh, the less visibility.

- Is air and light flow from outside the cage important?

- Do you need to have visibility–or should you restrict it?

- Economics: tighter, heavier mesh and solid alternatives can be heavier and more expensive.

Download Our Industrial Security Guide

Every facility fights a constant battle to keep its equipment and product safe and secure from theft. You want to maintain access for high-value items while also limiting availability only to those who really need to handle them. Our new guide to industrial security is here to help you find the right security options to fit your operations.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.