How to Specify Pallet Rack Safety Netting

A guide to size and styles

Any aisle that overlooks an area where people work, shop or walk should be protected against falling items, and rack netting is one of the most common ways to do that. It’s relatively inexpensive, full-time protection that can also help you maintain NFPA flue space requirements.

Net type: modular or standard

You can select modular or standard safety netting, and each has its proper application. Modular nets cover a single opening in standard sizes, but not entire bays. They are more versatile and easier to install. A standard net can cover an entire bay or long series of them in a row and requires more tools and time to install.

Standard netting specification

Standard rack netting covers full bays, or a number of them depending on configuration and facility needs. Rack nets can easily be configured to cover long rows in continuous runs of netting. Anywhere people walk beneath a row of stored pallets is an ideal place for rack safety netting.

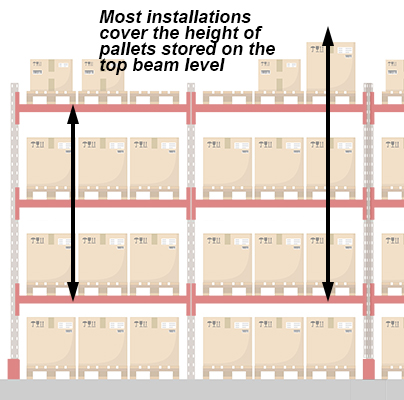

How much vertical coverage?

To determine the rack netting height, measure from the lowest covered level—typically every level above, but not including the floor—from the bottom of the lowest beam to the top of the highest point. That high point can be the top of the uppermost beam, but with extensions you can cover the top rack beam level with netting protection to guard top-level pallets. To measure that, measure from the bottom of the lowest beam to the top of the tallest anticipated load, including the height of the pallet.

The most dangerous storage position: Product stored on the very top beam can fall from more than twice the distance of product stored on the second level. That level is more important to protect than others, but it can be the most difficult. If the rack system was specified with extra tall uprights, you can install rack netting to the upright. Otherwise, you must install extension hardware to add netting to guard the topmost pallets.

Don’t use third party attachments. Remember that hardware or zip ties are usually the weakest links in your system. Use only those specified and supplied by the manufacturer of your rack netting. Don’t buy secondhand hardware or ties to attach your netting.

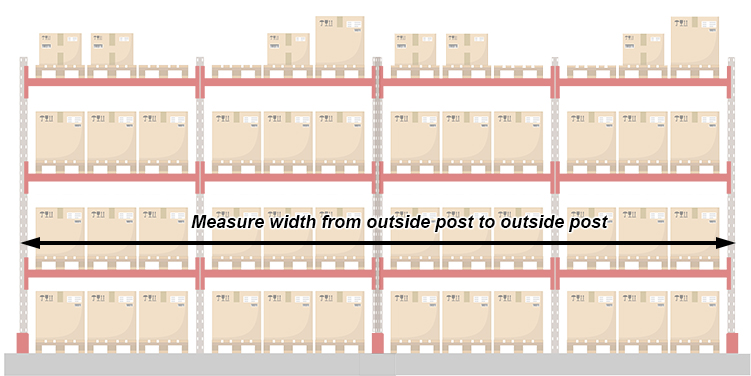

How wide should the net be to cover all bays?

- Measure the entire length of the row you need to cover, from the outside of the rack columns on each end. This will be a number that includes the beam widths plus upright frame widths and covers everything between the outer two posts. If you aren’t covering the entire run, measure between the two posts that will include the safety netting installation.

- Measure bay length from inside post to inside post. Verify the length of every bay, as beam lengths and installation procedures can vary. This is a critical step to ensure your net covers every bay correctly.

- Measure upright post widths. When rack nets cover multiple bays, upright widths must be accounted for while you’re specifying the net so that you have a tight, proper fit. The uprights must be accounted for in your configuration.

Depending on the manufacturer and installation guidelines, you may need multiple net sections of various widths along a row of rack to provide adequate protection.

Read more: Pallet Rack Falling Item Prevention

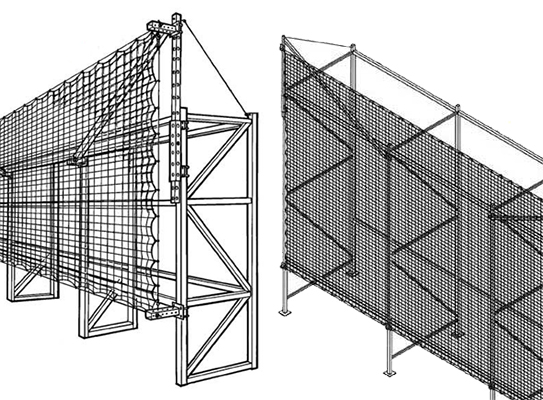

Determine installation type: flush or overhang

Above: overhang (left) and flush mount (right) pallet rack safety netting installations

If your pallets overhang the back of the rack by 3” or less, you can flush-mount your nets. This means that netting is attached directly the beams and uprights. Do this only with properly-specified, heavy-duty ties. Don’t use ties that have not been verified by the netting manufacturer. Most will provide the exact ties needed for safe installation. If your pallets overhang the back beam by more than 3”, you’ll need offset hardware to provide adequate clearance. This requires additional, specialized hardware that allows the room for safe operations.

If your pallets overhang the back of the rack by 3” or less, you can flush-mount your nets. This means that netting is attached directly the beams and uprights. Do this only with properly-specified, heavy-duty ties. Don’t use ties that have not been verified by the netting manufacturer. Most will provide the exact ties needed for safe installation. If your pallets overhang the back beam by more than 3”, you’ll need offset hardware to provide adequate clearance. This requires additional, specialized hardware that allows the room for safe operations.

Rack netting capacity

The heaviest load being your rack netting dictates the style of rack net. If your net must retain smaller items, smaller mesh is available to help retain those items. Standard rack nets come with capacities ranging from 1,250 to 5,000 pounds, but we can handle heavier pallets with custom designs. These capacities should be evaluated by a qualified professional if you aren’t sure about your loads and the potential for accidents.

Make sure your net can hold a full pallet: When you rate a net for capacity, it must be able to contain the weight of a fully loaded pallet, not a single carton. While full pallet falls are less likely than single cartons, it can happen and your net must be capable of handling it to achieve the rated capacity.

Mesh sizes: Be sure your mesh size can contain the smallest items you’ll store on the rack. Usually that’s boxes and cartons, but you should also consider what’s stored inside the cartons in case one breaks. If a pallet is struck and a box shifts, and the box breaks, can the mesh catch the box contents? Imagine a can of soda falling twenty feet towards workers on the ground. You may want to consider finer mesh or even a liner for these types of loads.

Read more: Comparing Pallet Rack Guards: Flexible Netting vs. Wire Mesh Panels

Specifying modular netting

- Modular safety netting covers a single opening (or a series of them using multiple units). It’s easy to install without tools or specialized measurements because these nets use built-in connectors that connect directly to teardrop or slotted uprights. You can add additional carabiners to modular nets to increase support. Modular nets offer capacities up t0 1,600 pounds.

- Modular designs let you “stack” nets on and around each other within a bay. You can install one on top of another to gain more strength and coverage. For instance, a single, 8’ wide bay with four beam levels would require three nets for full coverage of each beam level within the bay.

- One key reason people use modular nets is that they’re easier to access. They allow you to disconnect the net without tools, do needed work on the inside of the rack and then reconnect it relatively easily.

Modular net is very easy to specify. Select the width of your bay, based strictly on beam width. All modular nets are 5′ tall and range from beam widths of 8′, 8′-6″, 9′. 10′ and 12′. They cover a single beam level between two uprights so you can choose which levels and bays are covered. They do not have options for extensions above the top beam level.

Specify for your operational needs

Safety netting can be complicated, so don’t hesitate to ask questions and work with qualified experts. Particularly for larger installations with complex layouts and heavy loads, be sure that rack safety is specified into the rack itself. Make certain your rack safety net is specified for long term and accounts for the worst-case possibilities; when it comes to rack safety, too much is much better than not enough.

Download our Pallet Rack Guide

Pallet rack enhances your warehouse and improves overall facility performance when correctly specified, laid out and installed for the right load in the right positions. Check out our guide to specifications, styles, accessories and applications with expert tips from our employee-owners. You’ll find quick, useful information on racks and how you can use them more effectively.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.