Gapping Conveyors: A Guide to Types and Applications

How to create uniform gaps between conveyed loads

What are gappers?

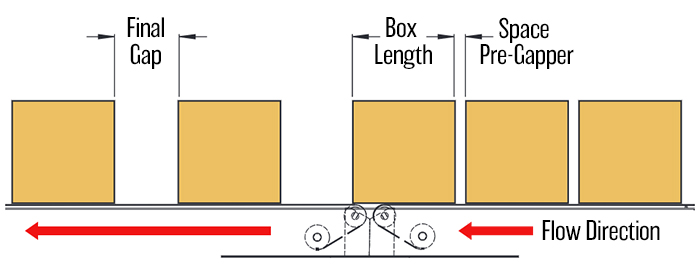

- Gappers combine two separate belts that convey at different speeds, which creates a gap between loads on the conveyor.

- Gappers are slider bed conveyors, and are considered an accessory that functions in a broad variety of applications.

- Blow-through type gappers are more basic, less expensive and simpler. They run at fixed speeds that create the gaps necessary for the next process on a conveyor line. They’re used for applications that transport or sort uniform loads in size and type. A distribution center that ships out only one or a very limited range of cartons is a good example of a blow-through application.

- Gap optimizers are faster, more expensive and provide better throughput for a broader variety of loads. These gappers create uniform spaces between loads of different dimensions and weights. Optimizers adjust their speed based on sensors and control protocols. They’re often deployed for high-throughput, e-commerce and 3PL applications that require variability and speed.

Sortation gaps

Because sortation systems need to scan and divert cartons at high speeds, they’ll need a gapping conveyor to ensure fast and accurate throughput before loads enter a sort zone. Many types of sorters need uniform gaps to correctly scan and divert loads. This also helps increase a sorter’s throughput and reliability.

Machines and packaging integration

Processing packages through an insert void filler, passing through a scan tunnel, applying a label, taping a carton top, shrink wrapping a load or any other number of packaging functions can require precise gaps. These gaps allow time for the process to execute before the next carton enters the machine. You can sometimes do this with accumulation buffers, but a gapping solution upstream of the packaging machine often works better and more reliably.

Adequate gaps give packages room to turn during merging and combining. The gaps give your system time to print and apply labels, for camera systems to read barcodes, weigh packages, or create proper spacing for the sorter to operate.

What are your gapping application considerations?

- The load profile: dimensions, weight and other characteristics of all loads on the conveyor system

- How much gap will you need between items? Is it always the same?

- What happens after the gap–sortation, machinery, manual processes, sensors, etc?

- What else in the design and overall flow should you consider?

Other applications for gappers

- Use gappers to separate cartons for some manual operations, allowing operators to easily access loads with consistent gaps between them. This gives a worker time to grab, inspect, rotate, fill, assemble or perform other functions.

- Gaps are also necessary for sawtooth merges and some spurs.

- You may need to create gaps ahead of sensors or scanners on your conveyor system.

- Gaps may be useful for some pushers or rotators.

- Gappers are often used preceding inline scales.

Gappers create precise, uniform gaps to help facilitate a variety of functions downstream of them on the conveyor. Using a gapper helps you create consistency and faster, more reliable operation for machine integrations, sorters and manual processes.

Download Cisco-Eagle’s guide to conveyors & systems

Well-executed conveyors and systems will optimize your operation–and we can help you make that happen. Cisco-Eagle’s detailed guide to conveyors gives you advice from our expert employee-owners, links, articles and more.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.