Warehouse Safety: Pedestrians, Workstations and Forklifts

Protecting people in workstation areas from forklift accidents

Above: work areas facing away from an active traffic aisle with pallet stacks that impede visibility for both pedestrians and forklifts.

Forklift accidents make OSHA’s top-10 list every year without fail because forklifts are ubiquitous in American industry and interact with hundreds of thousands of people every day. One of the key places to prioritize safety is for pedestrians—the people on foot who work near and walk around forklifts on a daily basis.

Forklifts and pedestrians don’t mix, but we have to make it work

While drivers get injured due to a variety of circumstances, pedestrians are hurt more often by forklifts. NIOSH’s long-term studies confirm this: Of forklift accident victims, 20% were workers struck while on foot. Another 16% of victims were workers crushed by a forklift, not including overturns (which happen to drivers, not pedestrians). Totaled, that’s 36% of all forklift-related injuries.

It’s an old, true adage that for people struck by, crushed under or run over by a forklift, there are no minor accidents. These are heavy, dense machines that aren’t particularly maneuverable moving up to 8 miles per hour.

What are the most dangerous areas for warehouse pedestrians?

- Crossing aisles and other areas

- Blind and low-visibility areas

- Docks, shipping and receiving areas – exterior

- Dock areas – exterior

- In rack and other warehouse aisles

- Picking areas

- Workstations and designated work cells

Warehouse work cells and work areas

This article focuses on work cells and workstations, which can be among the most dangerous operational areas when forklifts and pedestrians mingle. These areas are typically dedicated to some kind of focused work: picking, packing, assembly, administration or other activities. People are working, talking and using their minds to execute tasks, and they’re likely to be less focused on their personal safety than on the tasks at hand.

What are some of the problem areas, and what solutions are available?

Unguarded work areas: focused people with traffic nearby

This workstation is extremely dangerous. Setups like this will eventually cause an accident.

The pedestrian can easily back out of her work area and into the path of forklifts emerging from a narrow pallet rack aisle. This issue can easily be fixed with a fixed guardrail parallel to the aisle. Other ways to address this issue include safety sensors, gates and visibility aids like mirrors. The best way remains a hard physical barrier, which can prevent mistakes by either the worker on foot or the driver by physically separating them.

See more: Robotic work cells with frequent forklift traffic – problems and solutions

Work cells near traffic aisles

Good traffic management means that you should already have designated “go, no-go” areas for both forklifts and pedestrians. This is often achieved with painted floors or graphical floor stripes, and these are good steps. But as drivers hurry, they may cut corners. You can prevent this by installing a few feet of guardrail at corners (as illustrated above). It’s even more dangerous if the area near the corner hosts a work cell where people are constantly present. Use this technique to protect the area and prevent wide turns from becoming tragedies.

Forklift aisles near work areas

In this image, there is a defined pedestrian lane clearly marked to help people understand that forklifts may emerge from between the cross aisles. This is a strong method for protecting pedestrians from forklifts, but may be inadequate due to blind corners. Note that the hard rails are wood, which isn’t strong enough for certain forklift impacts. Solutions like warehouse safety sensors help alert people to the presence of forklifts or other traffic that may intersect with them.

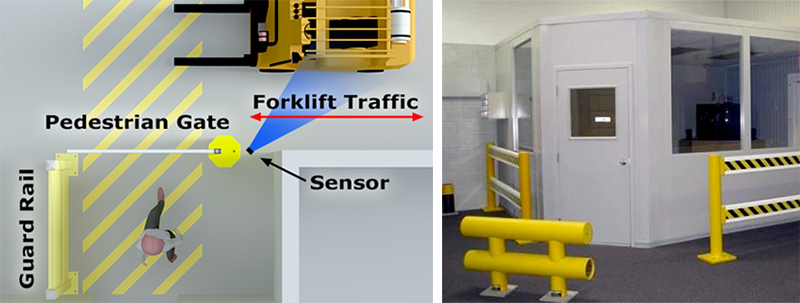

In-plant offices, warehouse entry doors and other “blind” areas

Work cells can often be placed beneath mezzanines, inside modular buildings or in offices with egress doors that are adjacent to or directly in the path of forklift traffic. Many times, people emerging from these areas have little or no visibility when they do. Some solutions include:

- Install guardrails, barriers or bollards that prevent contact between forklifts and pedestrians.

- Use motion sensors that alert drivers and pedestrians through walls and doors.

- Install gates that halt the pedestrian’s progress into a busy aisle, forcing them to slow down and look. These gates can be manual or sensor-driven automated systems that control the interaction more directly. Both types of gates have their place.

The right solution depends on the degree of visual impairment, the situation and traffic levels. Some solutions may involve a blend of these safety upgrades.

Mobile workstations

Mobile powered workstations are popular because you can roll-powered equipment anyplace you need it. Powered stations even let you print, use computers and power other devices away from fixed positions in your facility. This reduces walk times and increases the amount workers can do without returning to fixed positions, which can be highly productive. But it introduces high-focus tasks into areas of the warehouse like picking aisles or receiving areas or packing lines that can’t always be protected with guardrails, gates or sensors.

You can implement ZoneSafe or other proximity-based alert systems that don’t rely on a fixed location to help deal with this. Forklift drivers should always utilize their horns as they approach any pedestrian.

What can drivers do to protect people in workstation areas?

Any guardrail, sensor or gate can be rendered useless if people do not adhere to facility rules. Drivers should always sound their horns when they emerge from aisles, out of trailers or around corners. They should make eye contact with anyone near them as they pass. It’s incumbent on drivers to give pedestrians the right of way, but also to signal them which way they are going with simple gestures.

Importantly for workstation safety, drivers should never drive near anyone who is in a fixed position and focused on a process or piece of equipment. Don’t drive behind workers picking from racks or engaged in counts. Stop, honk and wait.

Pedestrians are responsible for their safety

When you’re working near forklifts, the person with the most to lose is you. Always adhere to guidelines, assigned exclusion zones and other areas designated safe. When you’re near a forklift, give it space. It can’t steer or brake as easily as a car. If the driver is driving forward with elevated forks, realize that they may not be able to see you. Behave as if they can never see you. In particular, be careful of tail swings, reversing forklifts and forklifts emerging from aisles.

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.