Forklift-Pedestrian Safety: Docks, Shipping and Receiving Areas

Shipping docks are a hazard point in most warehouses

Because shipping docks are busy, sometimes chaotic areas, they can become a safety hazard if not properly managed. During a busy shift, you may find multiple forklifts, carts, walkies and other traffic trying to work across a series of bay doors, all with pedestrians potentially in the same areas. They can adjoin staging areas, which often allow even more forklifts and pedestrians to work in the same, shared area. That’s where accidents are most likely to occur.

Where are the shipping dock pedestrian danger points?

- Forklifts exiting trailers into pedestrian areas. Trailers are natural blind spots for both drivers and pedestrians.

- Visitors wandering the area: Because drivers and other visitors are often found at dock areas, they may be unaware of your safety rules and training.

- Intense activity concentrated around arriving and departing trucks: These often require both drivers and workers on foot at the same time.

- Noise and visual obstructions during loading/unloading: During a busy time, docks can be occupied by multiple stacks of pallets, parked forklifts and people.

Limited visibility and dark conditions inside truck trailers are a problem

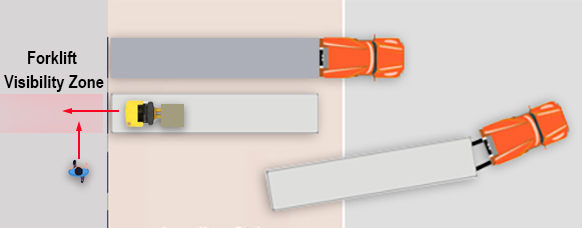

Drivers backing out of a truck may not see a pedestrian, who is also busy working or passing nearby. When they exit the trailer, their field of visibility is limited to its opening, so they can’t see a person walking perpendicular to the trailer toward them.

When drivers are inside a trailer, they’re focused on pulling the pallets out and backing into your dock area. They’re concentrating on getting it right.

Above: forklifts engaged in unloading a trailer has extremely limited visibility. Its driver is usually reversing out of the trailer, and physically cannot see the approaching pedestrian—or anything else—outside that tight rectangle of visibility defined by the trailer and dock door. At the same time, pedestrians cannot see the forklift until it emerges. When both parties are busy and hurried, this can be a dangerous scenario.

Sometimes drivers are also crossing a dock plate or lift as they exit trailers, which adds an extra point of distraction and focus. It’s usually dark in trailers. Pallets can be poorly stacked, forcing workers to take extra care accessing them. It can be cold or very hot. The point is, drivers are focused on their load and the task at hand as they back out, which means they can’t fully focus on what or who is behind them.

Install forklift warning lights

There are a number of warning light options, and all are economical, effective and easy to install. They attract the pedestrian’s eye as they slide along the ground and appear seconds before the forklift backs out, providing a clear visual indicator that something is emerging from the truck. They aren’t the be-all, end-all safety addition, but given the low cost and ease of use, they’re advisable for any truck operating in a warehouse environment—particularly near dock areas.

We recommend that given the very low cost and good effectiveness, every forklift run with approach running lights. They are excellent for truck unloading applications in particular but effective for almost everywhere in a warehouse.

Utilize sensors and proximity warning systems

Dock safety sensors warn forklift drivers and pedestrians to help them notice each other.

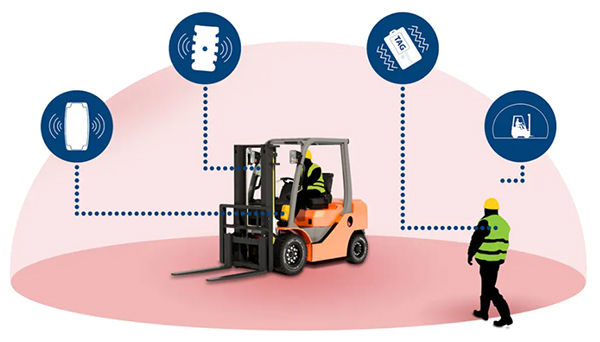

Sensors and alert systems have come a long way and can be a significant safety enhancement when properly configured. Remember that when they’re in a hurry and pressed for time, people aren’t going to be as attentive to safety. Think of warning sensors as audible and visual reminders when possible problems are detected.

Whatever technology you use, it must exist within and integrate into your safety process and training protocols.

You can also use tag-based proximity systems that warn drivers when pedestrians are in the area. These tags are worn by pedestrians and notify the driver by flashing and vibrating when the tag enters a defined zone. The driver doesn’t have to see the pedestrian to know they’re nearby. These systems don’t require any sensors or warning devices to be installed on walls or ceilings and can “see” through solid surfaces like warehouse walls.

Separate people and forklifts by process and barriers

Our recommended pedestrian safety process relies first on separation—the concept that whenever people and forklifts can be separated, they should be.

Separation is difficult at the docks, where so many people often work so frequently with active vehicle traffic. But you can achieve at least some separation by designating timeframes where people must clear the area while forklifts are at work.

Standard training should apply: forklifts should honk, deploy backing sensors and other safety measures. Pedestrians should always be aware of their own safety when working near forklifts.

Exclusion zones work at docks, too

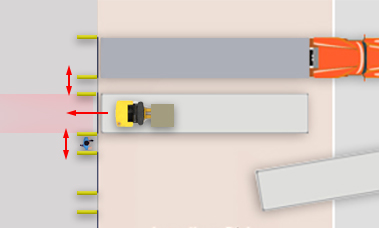

At the very least, people shouldn’t be working near the most dangerous point, the blind spot directly outside the trailer when a forklift is inside.

Above: short guardrails installed perpendicular to door openings to prevent people working near the docks from drifting into the blind zone directly outside the truck trailer.

- When possible, install short guardrails in the gaps between doors. This is the most dangerous area because people working in these areas can easily step laterally in front of the dock door and into a forklift’s path as it emerges. Neither party has time to see or react to the other when the pedestrian is so close to the outer wall. Guardrails may not be practical for every dock, but they also add more protection for the doors and door frame materials. It’s a simple and effective way to cordon of a few feet of safer, “reaction” space for both parties. Distracted people can’t easily drift into a moving forklift’s path when you use this technique.

- Design those areas closest to door gaps so that people don’t work there. Don’t put computers, workstations or scales there that workers on foot might use. These gaps between doors are often used for such operations because it’s otherwise unused space. This encourages people to be in that high-danger area.

- Use visual aids such as mirrors and trailer lights to indicate when a trailer is occupied by a forklift. Systems that light up when a forklift is inside are relatively economical and let people working in the dock area know a trailer is occupied. They can help people inside understand that a forklift is in the trailer and could be backing out at any time.

- In general, removing people from the immediate area around trailers is best. Sensors, warning lights and training all work, but the absence of pedestrians is the best policy. This may not be a hard exclusion zone, but can be part of your process and training.

Visitors wandering on the docks are a real problem

Untrained people like truck drivers, service technicians and other visitors shouldn’t be allowed to roam your dock areas freely. They aren’t trained in your forklift safety process and are riskier than employees in general. They can present significant liability challenges. The person most at risk from forklift accidents is likely an untrained guest who isn’t ready for or cognizant of the dangers. This is particularly true when these guests don’t usually work around forklifts.

How to protect guests from forklift accidents:

- Enforce all PPE guidelines such as vests, steel toes or hard hats.

- Keep exterior personnel doors locked and secure from the outside. No one should enter without proper clearance.

- Install dock door security cages that allow people to enter your warehouse, but contain them in safe areas until admitted.

- Conduct training prior to admission for authorized guests. Ensure they only travel where necessary.

- When possible, provide escorts for those who must enter forklift traffic zones.

- Create walkways separate for drivers and other guests to areas like lounges and restrooms.

Read more: How to Specify and Design Dock Door Security Cages

Noise, visual obstructions and fast pace

Above: tall, stacked pallets stacked near a busy truck dock. People may walk through or around them, into the path of moving forklifts. Neither party can see the other easily in this scenario. Loaded pallets should be moved away from any area where people and forklifts can mingle. In this instance, either move the pallets farther away or keep people on foot away until they are cleared by lift trucks.

Docks and staging areas are conducive to forklift-pedestrian accidents due to the nature of the area. Traffic flows through it in intensive spurts as trucks are loaded and unloaded, within tight spaces. As mentioned above, trailers create blind spots, but they aren’t the only factor. If you stage at or near the docks, that means loaded, tall pallets in walkways and lanes that reduce visibility. Avoid staging near the loading/unloading areas whenever possible, and designate exclusion zones for pedestrians.

Other potential obstructions could include parked forklifts or anything else large enough to cause forklifts to change course, or pedestrians to be obscured to drivers.

More forklift-pedestrian safety resources

- Bureau of Labor Statistics: Forklift Safety

- Downloadable Guide: Forklift-Pedestrian Safety (PDF, opens in new tab)

- How to Help Drivers Park Faster & Safer at Your Truck Docks

Download our white paper: “shared space is a dangerous place”

In an ideal world, forklifts and pedestrians would never interact, but we don’t live in an ideal world. Download our guide to training, methods, technologies and processes to improve safety when your people operate near forklifts. Topics also include traffic planning, environmental factors, speed limits and much more.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.