Forklift Proximity Detection – Do More Zones Matter?

Review what is gained when you layer more protection

ZoneSafe Proximity Detection System Inquiry

You’ve seen them pass so close in your facility it stopped you cold. Keeping forklifts and pedestrians from collision (or even close encounters) is a critical element of safety within any facility that uses both. Creating a safe culture that improves these interactions is the goal of any team, and there are many solutions available.

Outfitting your workers and trucks with proximity warning systems is a solution designed to improve these interactions. These systems are a crucial component of occupational safety strategies, significantly diminishing the likelihood of accidents and incidents between pedestrians and vehicles, and effectively fostering a culture of heightened safety awareness among employees

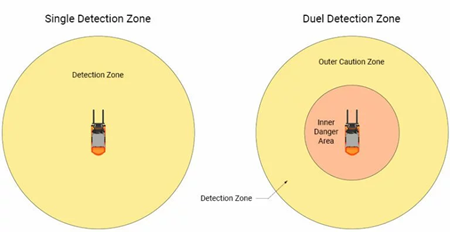

As proximity warning systems evolve, they now boast new features. Notably, some are exploring dual detection zones, with the thought of extra protection. This innovation prompts us to question: does an extra detection zone boost accident prevention effectiveness?

Zone of protection

Proximity warning systems establish an unseen, flexible safety perimeter around potential dangers like vehicles, machinery, and valuable assets. Workers in proximity usually don tags on their apparel that activate in close vicinity to the hazard. Upon entering the safety perimeter, the system triggers auditory, visual, or vibratory warnings, alerting both equipment operators and nearby personnel with tags about the imminent danger, enabling them to react promptly to avert accidents, thereby safeguarding themselves and others.

Comparing dual and single zones

Upgrading to a dual-zone system introduces two safety layers: a “caution zone” and a more critical “danger zone.” Initially, entering the caution zone triggers a warning, allowing for earlier hazard recognition. This preemptive approach seems to enhance safety, giving extra moments for safe decision-making, and potentially averting risks.

While effective, the single-zone system now seems limited compared to the dual-zone’s broader safety net. Does this initial conclusion hold up?

The complexity conundrum and alarm fatigue

When applied to safety, with sophistication comes complexity (as always). More system features could lead to potential confusion, necessitating clear guidelines and training. In essence, you’re retraining your workforce to understand which alarm matters! This doesn’t sit well with our primal brains, which crave contrast to ensure attention to emergencies. Ensuring that the signals for both zones are distinct is crucial; a mix-up could have serious implications. Also maintaining both sensors to create these dual zones means more time spent in that area, and more equipment (and backup equipment) is necessary.

In safety-critical environments, the prevalence of alarm systems is high. Yet, their effectiveness might wane if they become too frequent, leading to alarm fatigue. This phenomenon can cause staff to become desensitized, risking complacency. Here, simplicity could be the key. A single, clear alarm often proves more effective than multiple, less distinct warnings. You don’t want your zones to just become pockets of background noise.

Read more: How forklift warning lights help separate

Simplicity for safety

Often, simplicity yields the best outcomes. It’s evident that establishing a safety perimeter or buffer zone around potential dangers is crucial, but achieving this through a blend of proximity warning technology along with tangible measures such as barriers, cones, and signs can effectively maintain safety without overburdening workers.

Upgrading forklift cabs with the latest technologies is not going away. Neither is having an operation that is bustling and moving at a breakneck pace to service customers. As the complexity in vehicle cabs increases, maintaining clear, straightforward warning systems is essential to minimize errors and maintain high safety standards.

Read more: How well do your forklift drivers see?

Don’t just think about the zone

It’s not just about how many zones you have. If the sensors you’re choosing to employ combine to create a dual zone, but the dual zone isn’t effective, then what are you left with? As with any means of providing pedestrian protection, the systems you choose must have the pedigree to achieve your safety goals. Make sure you have an idea of the risk areas you want covered, and then see how applying proximity detection will fit that.

Download the forklift/pedestrian safety guide

Keeping pedestrians safe in busy operations is an ongoing process critical for any industrial facility. With that in mind, we’ve published a guide to forklift-pedestrian safety that highlights the factors, suggests solutions and presents information on this critical issue.

Download the guide today

Evan Fleishacker