All Squared Away: Carton Quality

Cartons with square corners form stable, damage-resistant palletized loads

Cartons affect the full sequence of warehousing operations, but are frequently overlooked.

Besides carton sizes, you must also consider carton construction. One box out of square may not matter much; over a whole shipment, un-squared cartons can cause issues up and down the line. They don’t stack well, may not convey correctly and could result in product damage. In fact, you may pay higher shipping costs due to the size, composition and condition of the simplest thing: the carton.

The value of squareness

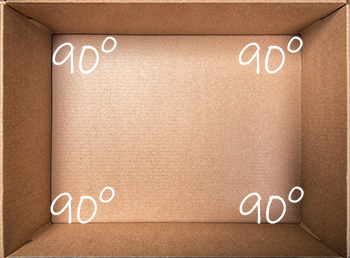

What do we mean by “square”?

A squared carton is 90 degrees at every corner, with each side perpendicular to the next. Out-of square cases are 30% weaker than square ones. The downstream effects of carton squareness are significant:

- Squared corners allow you to use more of the carton space and make your packing team’s job easier.

- Better palletized loads. Square boxes align better when stacked. When the corners of stacked cases align, they support more weight.

- Less product damage. A tidier, stronger stack of cartons is easier to stretch wrap and less likely to overhang the pallet.

- Well-built cartons suffer less damaged during transit.

- Forklifts can damage bulging or overhanging cartons.

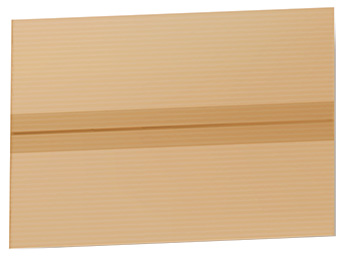

vs.

vs.

Read more: How to Make Packing More Efficient

How to create perfectly square cartons

Your options for execution range from manual to semi-automatic to fully automatic.

- Manual case erection may work if your operation is lower volume, but it’s harder for a person to create perfect squares than for a machine.

- As volume increases, you may find that your team has to form cases in advance of a big rush, which eats up space.

- Fully automatic case erectors interact with other equipment to provide a steady stream of perfect boxes. They require a much bigger time investment than other options, and they almost certainly won’t be the least expensive course you could take. Two factors make an operation a good candidate for a fully automated system: very high volume and a fairly uniform case size.

- Between manual methods and a fully automatic system, semi-automatic case erectors provide consistently square cases, without the same investment of time and money as a fully automated system. If your volume need is low to moderate, semi-automatic case erectors and sealers may work well for you.

- A volume of about 500 cases a day is the range for semi-automatic solutions.

Video: Automatic carton erector-sealer

Sometimes automated tools help you attract talent. Case erectors reduce corrugate wrangling with a tape gun, which is time consuming and can result in inconsistent quality and uniformity.

Tips for creating sturdy palletized loads

- Avoid overhang. All boxes should sit comfortably within the dimensions of the pallet.

- Arrange the cartons as close to the edges of the pallet as possible. This makes strapping and stretch wrapping easier and more effective.

- Stack heavier cartons on the bottom layer. This creates a stable base and avoids crushing loads beneath.

- Think cube, not pyramid. If you have a mixed case sizes, incorporate the smaller ones rather than stacking them on top in a triangle pattern. A pyramid is less structurally secure than a cube. Your upper layers are never wrapped as well as the lower ones.

- Aim for even weight distribution. Pallet rack capacities usually assume evenly distributed loads, and individual pallets are more stable when they’re loaded evenly as well. The even distribution guideline applies to the contents of boxes as well as the position of boxes on the pallet.

- Add stabilization. Using flat sheets of cardboard between layers can help prevent deformation of the load during transit.

More resources

- Guide to pallet rack load distribution

- Information about robotic palletizers

- Our partner Lantech on the value of case packing equipment

Jessica Haring