Seven Ways E24 Rollers Improve on Conventional Motorized Roller Conveyors

What can you expect from 24-volt rollers?

When Hytrol introduced its E24 powered roller conveyor system there was a splash – and rightly so.

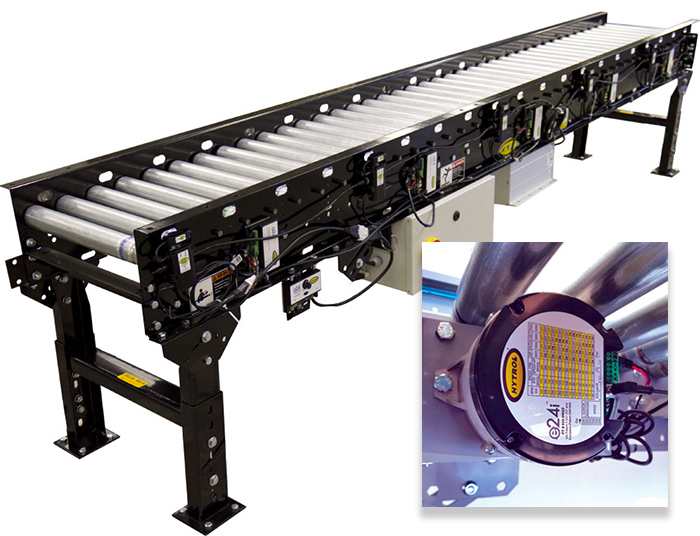

E24 is a brushless, gearless, low RPM, high torque motor that drives conveyor rollers reliably and efficiently. The external motor provides exceptional flexibility, superb heat dissipation, and a robustness that cannot be achieved with motors embedded in conveyor rollers. But what really makes E24 superior to the conventional motorized roller conveyor?

#1: It lasts longer

E24 lasts longer. Its 125,000 hours of expected operational life mean that it can last you over 14 years of pretty much continuous, 24/7 operation. The conventional motorized roller conveyor runs about 20,000 hours: a bit over two years of 24/7 operation.

#2: E24 has only three, count ’em, 3 moving parts

Every moving part, no matter how well manufactured and designed, is a chance for failure. People are seeing reduced maintenance costs and more reliability as a result.

#3: The E24 has an external motor

That means one motor works for all roller widths. This gives you greater flexibility and ease of maintenance or repair if needed. With conventional rollers, every roller width means you have to have a different motor. That’s needless complexity that you can skip with theE24.

#4: It’s gearless, so it’s quiet and consistent

This makes it very quiet. I’ve seen it run a few times, and it’s an amazingly silent machine. This also means you have one motor for every speed. You have one motor to stock–that’s it. Conventional rollers means different gearing needed for different speeds and more rollers to stock.

#5: The motor is external, in aluminum housing bolted to the side channel

This gives you outstanding heat dissipation and longer motor life. When conveyors have motors inside the roller tube, small moving parts are present and heat dissipation is poor.

#6: Its external motor means that you don’t have to route wires through small holes.

This can alleviate possible damage during installation. With conventional motorized roller conveyors, wiring has to be routed through the motor shaft and side channel, complicating installation and creating the potential for damaged rollers.

#7: The E24 motor is bolted to the side channel

This gives you higher torque and strong, simple mounting. This can actually reduce the number of drives needed for your conveyor system.

Download Cisco-Eagle’s guide to conveyors & systems

Well-executed conveyors and systems will optimize your operation–and we can help you make that happen. Cisco-Eagle’s detailed guide to conveyors gives you advice from our expert employee-owners, links, articles and more.

Download the guide today

Tags: Hytrol, Conveying, roller conveying systems, Conveyor, Material Handling, power rollers

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.