Building a more ergonomic material handling operation almost always equates to building a more efficient one. People who don’t need to bend, strain or lift as often are usually more effective, faster and less prone to injury. If it takes energy or time to turn, lift or maneuver a load, it’s this simple: you’re losing productivity. Many companies use scissor lift tables to help them lift heavy and bulky loads and can make the process even better by understanding what happens when that load reaches its desired height.

Scissor Lift Platform Options for Improved Productivity & Ergonomics

Tags: ergonomics, facility safety, Conveyor

Posted in Lifting & Lift Systems|

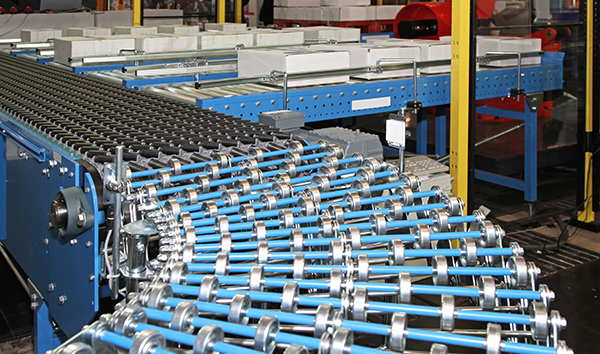

Conveyors: Belt or Roller?

Belt and roller-powered conveyors are specified for a variety of reasons within a given conveyor system. The reasons almost always come down to load characteristics and functionality. Both can be used in transportation, sortation, and accumulation applications. This article delves into the differences and the specific advantages each conveyor type offers.

Tags: Conveyor

Posted in Conveyor Optimization|

Harnessing Automation to Improve 3PL Performance

As your 3PL grows and attracts more clients, products, and infrastructure, your product movement and storage capacity won’t be able to keep up with the increased volume. Growth is a great problem to have, but it’s still a problem.

Intelligent warehouse automation is an effective way to create better flow, enhance efficiency, ramp up throughput, reduce errors and improve your processes. Introducing automated systems into your current warehouse environment can produce drastic reductions in time spent on certain day-to-day activities.

Tags: Automation, 3PL, logistics, storage, warehouse, Third Party Logistics, warehouse flow, warehouse technology, Conveyor

Posted in Automation, Labor & Efficiency|

Conveyor Maintenance Tips to Reduce Downtime, Missed Deadlines & Headaches

Your conveyors are the unsung hero of your facility, delivering product quickly and efficiently at the push of a button (or automatically in many cases) where it’s needed, when it’s needed. Most people don’t think about their conveyors and automated equipment much, but if it breaks down, you suddenly can’t think of much else. You simply can’t afford downtime when material handling equipment is delivering your core business.

Tags: Conveyor, service, conveyor maintenance, repairs

Posted in Conveyor Optimization|

Choosing a Replacement Electric Motor

When your conveyor motor stops working, do you know what you need to know to replace it quickly? How do you even know what the original motor was rated?

Tags: Baldor, replacement motor, Conveyor, enclosure, electric motor, horsepower, rpm, frame size, voltage, motor, single phase, 3-phase

Posted in Conveyor Optimization|

Another Reminder: The Importance of Lockout/Tagout

We talk safety a lot, mainly because the environment we work in, and the customers we work with use equipment like forklifts and conveyors in areas where interaction with people is unavoidable. We believe the first responsibility we have to our customers, and the first responsibility our customers have to themselves, is safety. Many of the wonderful benefits of material handling equipment comes with the risk of injury. It’s powerful machinery, and people must pick from it, walk near, it or otherwise interact with it.

Tags: Conveyor, conveyor safety

Posted in Safety & Ergonomics|

The Critical Importance of Conveyor Emergency Stops

Take a look at your conveyor – do you think it’s safe? Are there sufficient guardrails? Are operators wearing loose clothing? Are visitors allowed near running lines? Because conveyor seems safe at a glance, it’s an often-overlooked hazard. Used correctly, of course, it is a safe way to increase productivity.

Tags: Conveyor, OSHA, industrial safety, warehouse safety, conveyor safety

Posted in Conveyor Optimization|

Robotics and End of the Line Packaging

The end of a manufacturing or distribution line is where the rubber meets the road for many operations. It’s potentially the last place where you have direct control of your product before it ships to retailers or direct customers. It’s where you can add a lot of value…or spoil a lot of value. The end of the line in many ways is more important to your company’s image as all its public relations, its websites, its brochures. It is often where your reputation can be made.

Tags: Robotics, Packaging, Conveyor, Automation, palletizing

Posted in Automation, Labor & Efficiency|

Conveyor Systems: Total Cost of Ownership

The amount on your purchase invoice isn’t the last time you’ll pay for that conveyor, but those ongoing costs of operations can be dramatically reduced by making good decisions at the point of purchase. Conveyor systems designed for future considerations slash costs and perform better.

Tags: Conveyor, warehousing, conveyor systems, ROI, Sustainability

Posted in Conveyor Optimization|

Gravity Conveyor: How Many Skatewheels do You Need?

Gravity skate wheel conveyor is probably the most economical conveyor option around for quick, portable movement of lightweight boxes, totes, or trays.

You see it used in shipping & receiving areas, in assembly operations, or as a transitional piece between workstations and powered conveyor lines. You can even slap casters on it for a conveyor that can be rolled in & out of use areas. We even plug it into gravity flow racks to create heavier-duty, FIFO flow storage.

For such a simple piece of conveying equipment — in fact the simplest — errors can and do crop up when it’s ordered incorrectly.

Tags: Hytrol, Conveyor, warehousing, Material Handling

Posted in Conveyor Optimization|