Scissor Lift Platform Options for Improved Productivity & Ergonomics

Your lift table can do more than just lift the load

Building a more ergonomic material handling operation almost always equates to building a more efficient one. People who don’t need to bend, strain or lift as often are usually more effective, faster and less prone to injury. If it takes energy or time to turn, lift or maneuver a load, it’s this simple: you’re losing productivity. Many companies use scissor lift tables to help them lift heavy and bulky loads and can make the process even better by understanding what happens when that load reaches its desired height.

What are we trying to accomplish?

- Better ergonomics: Your operators can position loads exactly where they need them to work better with the right lift and lift top. This means these loads are at ergonomic heights (in the “golden zone”), and also in the right orientation. Instead of an assembly worker walking around a component, they rotate it. This minimizes reaching, walking, stretching and straining. This boosts worker comfort as well as a decrease in the risk of musculoskeletal injuries.

- We want to be faster and more productive: Better ergonomic positioning naturally boosts productivity.

- Position our loads more precisely: If your people need to pull boxes from a pallet, a lift that both lifts and rotates makes that much faster and better. The same goes for any step in a progressive assembly line.

- Handle more types and sizes of loads: The right top lets you do more on the same lift. You’re more versatile handling different types of loads. Whether it’s rotating platforms for precise positioning or conveyors for easy transfer, you can handle more types of items. This gives you better ROI on the equipment.

- Integrate with existing material handling systems: Turntables and conveyors can interface with existing material handling systems, allowing for seamless workflow (into or off a conveyor system, AGV, AS/RS, or carousel, for instance).

The options for scissor lift table tops

What can you build into your lifting process?

- Conveyor tops: power or gravity rollers let you move the load along the top of the lift.

- Ball transfer tops: also allow load movement, but also rotation.

- Rotary tops and turntables: spin the entire load in place.

- Skid access brackets: brackets that allow forklifts to access flat loads such as sheets on the table top.

- Specialized handling tops: hold loads like rolls or coils in safely place during the process.

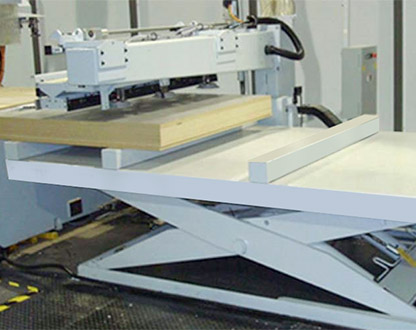

Conveyors and lift tables

Conveyors and lifts go together like peanut butter and jelly that optimizes movement and positioning. You can use conveyor tables mid-line to elevate a load for work or transfer. Often, conveyors are used to move loads easily along a table top without straining or sliding. You can seamlessly transition product horizontally with conveyors – and vertically with integrated scissor lifts. Conveyor lift table tops handle the same types of loads as the connected conveyor lines can. They are usually rollers conveyors, either gravity or powered depending on the application.

- For pallet conveyors, they can match to the floor level. When a pallet reaches the lift station, the lift can elevate it for transfer, stacking, de-stacking, assembly or further work. Many types of pallet handling can be enhanced by integrating conveyors and scissor lifts.

- For smaller loads like totes, cartons or components, the same dynamics can exist. lift tables can be set parallel or perpendicular to the line. The lift lets you reposition the load for further processes or transfers.

Read more: Integrating Conveyors and Industrial Lifts

Ball transfers allow flow and rotation

Ball transfers let you both move and rotate the load on top of a lift table. This is ideal for positioning and changes in work flow for assembly or packing. Care must be taken to ensure loads aren’t dropped off table edges, but this is usually solved with stops or brackets. You can place a lift table adjacent to a conveyor line for workers to divert loads. They can work the task, then move the load back to the conveyor line. They can rotate and reposition the load with ease.

Turntables and rotary lift tabletops

When you outfit your scissor lift with a turntable or other type of rotary top, it becomes much more functional than with a fixed steel top because you can now position the load rather than positioning the people who work on the load.

- Turntables can rotate manually or automatically.

- Manual turntables are rotated by hand, while automatic turntables may be controlled by a motor.

- You can add more functionality by combining conveyors or ball transfers with a rotating top or turntable.

- This concept lets you sit a lift between two conveyor lines, work the process, then swap lines using the lift as a transfer mechanism.

Rotating lift tops are an ideal and relatively inexpensive way to dramatically increase the lift’s functionality. The time savings alone of delivering work to people rather than people to work almost always justifies the investment.

Pallet positioning is a key concern

Because pallets are large, cumbersome and heavy, entire classes of lifting and conveyor systems have been created to service them. A class of lifts called pallet positioners adjusts the lift based on its height and facing to present workers with the most optimal way to stack or load a pallet.

- Floor-level pallet positioners let you load pallets by pallet jack, then load or unload them by rotating for easier access.

- Turntables can be powered or manual, depending on application, load type and frequency of use.

- Most commercial scissor lifts can be fitted with turntables to increase their efficiency.

Read more: Ergonomics and Pallet Handling

Brackets and specialized load tops

While these types of lift table surfaces don’t position the load, they let you access it easier and safer.

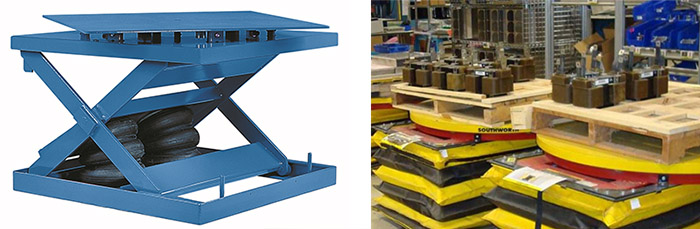

Above: this scissor lift features brackets that allow sheets to be positioned above the surface. This means that forklifts can pick up or place large, heavy, flat-bottom loads like sheet metal, skids, wood or sheetrock without palletization.

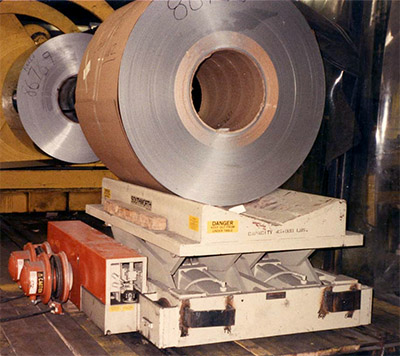

Above: coil handling carts can handle extremely heavy loads. Smaller crib type tops can be built for rolls and coils in almost any configuration.

A lift doesn’t only lift: it positions

When you examine the natural way people position, work on and transport products, it becomes clear that any single piece of material handling equipment can function in a broader way. Scissor lifts are by nature vertical transport mechanisms, but can also transport and position their loads to help make your operation safer and more effective. Many standard and custom options are available to help you build exactly the right lift for your needs.

Tags: Conveyor, ergonomics, facility safety

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.