How Dimensional Shipping Weight Affects You

Freight companies have changed how they calculate package shipping. Here's how to calculate and mitigate the impact.

If you haven’t taken a look at your shipping invoices lately or talked to your freight rep, you probably should do so before the day is out. Significant changes have been made in the way shipping costs are calculated and it will impact your bottom line – no matter what you’re shipping.

Why is this happening?

For years, carriers have struggled with how to accurately charge for the space a package takes during transit. If you’re a carrier, you can’t just charge for the space, because the heavier the item, the more fuel it takes to ship it, but if you charge based on weight alone and not for space taken, you’ll end up losing money on the vacant air inside boxes and packages. You also end up needing more and more cargo space as packages become larger and larger to protect the contents inside.

As a carrier with a finite amount of space available (aircraft cargo space, semi trailers, cargo vans, etc.), you need to make sure each cubic inch is profitable. There’s no money to be made in shipping air (the empty space inside a container), so carriers found a way to encourage shippers to reduce their packaging sizes, thereby enabling the carriers to ship more in the limited space available per shipment – carriers went to dimensional weight shipping for all freight.

What is Dimensional Weight Shipping?

Dimensional weight shipping is a calculation process that helps account for space taken by a package along with how much it weighs. It is probably the largest impact on shipping that has happened in the last 30 years – that’s how pivotal it is to your shipping operations.

Overall, the use of dimensional weight has the potential to increase your shipping costs 20% or more. Coming at the same time as annual base rate increases and combined with extraneous fees and surcharges for things like residential and remote deliveries, fuel surcharges, and “out of week billing adjustments” (for not including dimensions at time of manifest), shipping can increase into the 30% range this year.

Calculating the dimensional weight

Calculating the dimensional weight is a pretty simple formula:

(Length x Height x Width) / DIM factor = Dimensional weight

It basically calculates the cubic space a package takes then divides that total by the DIM factor, a number selected as the base weight for 1-cubic foot of space. Each carrier has their own DIM factor but the most common DIM factor number is 166.

From here it gets a little tricky – you still have to know the actual weight. Once you’ve figured out the dimensional weight, you compare it against the actual weight, and whichever one is the large of the two becomes the Billable Weight. The billable weight is then used to calculate the shipping rate by your carrier.

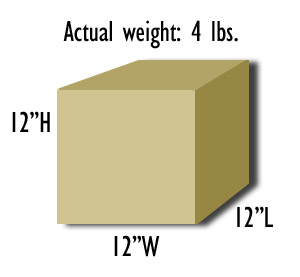

Here’s an example:

(12″ L x 12″ H x 12″ W) / 166 = 1728/166= 10.4 lbs. = 11 lbs. Dimensional Weight

Now, you compare the Dimensional Weight to the Actual Weight: 11 lbs. vs. 4 lbs. The larger of the two becomes the billable weight: 11 lbs. When multiplied by the ship rate to, say, Zone 2, you get a cost of $9.40 ship rate when using the dimensional weight, while using the actual weight nets you a cost of $7.11. That’s where the grumbling starts. You now see a significant difference in shipping costs. But, don’t whine for very long – it’s costing you money for every package that doesn’t have dimensions listed that leaves your shipping department.

What can I do to minimize the impact?

Minimizing the impact of dimensional weight on your shipping costs comes down to some very smart measures you should probably already be using. As in all lean operations, optimize, optimize, optimize!

There are some basic ways to reduce the impact to your bottom line of these new shipping rates:

- Make your packaging process more efficient – change packaging materials, reduce packaging sizes, refuse to ship “air”

- Renegotiate your shipping contracts for a larger dimensional factor or lower base rate, or, start looking at other carriers for better rates

- Drop products that are unprofitable to ship

- Change your shipping policies so that added costs are passed on to the customer for each order

Best practices to implement in reducing shipping costs

Boxes

- Conduct an impact study by analyzing the “Package Level Detail” in carrier reports to see if there are areas you can improve in (DIM weight vs. actual weight variances, surcharges for missing dimensional data, etc.)

- If you can’t find dimensional data on carrier reports, do a cube study. Measure the actual space needed to package an order and compare against the packaging being used. Work with your packing team to assure you are using minimal container sizes for safe shipment

- Choose the right size container every time by using cartonization logic software to evaluate order contents to help your workers in choosing the number and size of shipping cartons for each order. This software usually requires dimensional information and weight for each product, so you might as well bite the bullet and put someone on getting that data gathered and entered into your warehouse system. Your whole goal is to choose the smallest container that will safely deliver the products in the order

- Pick better dunnage with the goal of using less packing or more effective packing materials (air bags, pouches, bubble pack, etc.)

- Box quality can make a difference. Stronger boxes bulge less during shipment and keep dimensions true from start to finish

- If you’ve incorporated all of the above, consider box optimization by using custom box manufacturing equipment that builds the box to fit the order. UPS and FedEx have packaging labs and can help you with optimizing packaging. They want small packages, too, so they don’t have to build more facilities and buy more vans, trucks and aircraft

- Along with custom boxing, use dimensional scanners as the orders are packaged to record final dimensions at manifest time. This action helps prevent out of week shipping charge corrections

The Contract

Contracts are negotiable – even if you just signed it. When conditions change, don’t be locked into business killing terms. Renegotiate for better freight terms in the following areas:

- Modified Dimensional Divisor

- Cubic Threshold Modifications

- Existing Cubic Threshold Grandfathering

- Cubic Threshold Change with a Phased Approach

- Offsetting Incentives

Alternative Carriers

If all else fails, start looking into other carriers, particularly for products that are costing you significantly more than they used to. Consider looking at:

- Regional Carriers

- Parcel/Postal Hybrid Solution

- USPS

New rules to know

Anytime a service provider makes changes, there will be new rules along with those changes. Some of the rules to be very aware of are:

- Failing to include dimensional info on manifest ends in “out of week billing adjustments” and creates confusion in understanding what the total landed cost for shipping orders is

- Billable weight is the larger of actual weight or DIM weight

- Large package surcharges are incurred if the package cubic space (length plus girth [(2 x width) + (2 x height)] is greater than 130 inches, and may be subject to a minimum billable weight of 90 lbs.

- New dimensional weight rules include virtually all packages shipped via ground or air. Previously, dimensional weight shipping only applied to ground shipped packages 3 cubic feet or more and air shipped packages

- Domestic DIM factors: DHL – 139; UPS – 166; FedEx – 166

- International DIM factors: UPS & FedEx – 139

- The higher the DIM factor number the smaller the DIM weight will be

Mitigate added costs by taking action now

While the increase in shipping costs might be a concern, you can reduce its impact on you. Analyze your packaging operations, take a look at getting dimensional and weight information into your warehouse management system, optimize packaging through training and technology, and talk to your carrier about what they can do to help you improve shipping operations and cost. They have good reason to assist you – they want to carry more orders in every shipment in order to increase their profit margin. They can help you with yours, too.

In the near future, these factors will begin to affect some LTL and palletized shipping. This process has already begun, but has not taken root to the extent it has for package shipping.

Tags: shipping, freight cost, UPS, FedEx, carriers, dimensional weight

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.