Seismic Zones and Pallet Rack: An Evolving Situation

Mitigate damage potential and increase safety margins

Is your facility in a seismic zone? Are you sure?

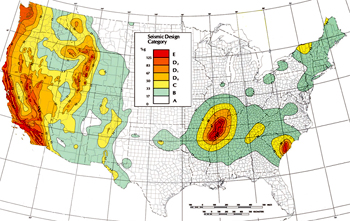

An increasing number of areas across the United States are demonstrating geological stresses and increased fault pressures that lead to earthquakes and smaller seismic events. So much more that our national seismic map was recently updated to include areas of the northeast and southern tier states not previously known for earthquakes, as well as enhanced zone classification in the inter-mountain west and known fault areas. Are you sure your pallet rack is correctly configured to withstand seismic ground forces?

There’s a whole lot of shaking going on

In an earthquake, no matter how small it seems, there are ground motion effects that impact the structural performance of not only your building but also of your storage rack systems and their contents. If rack is incorrectly specified, designed, installed, loaded or maintained, you run the risk of rack failure through collapse or overturning and potentially endangering workers. Even if the rack withstands a seismic event undamaged, inventory stored on it may come loose, toppling from shelves, falling through between beams or overturning.

Every purchase, installation, and reconfiguration of pallet rack is serious business

It cannot be stated strongly enough that any time pallet rack is added to or reconfigured in a facility you need to work with professionals who understand rack systems and who work with certified installers and manufacturers.

Compile and file the following information:

- Specific latitude & longitude of your location

- Stored content details of size, weight, commodity class, and unit loads

- Loading & unloading equipment information such as type to be used (helps in determining rack footprint and spacing needed)

- Operations characteristics such as activity levels, work zones, and load/unload schedule

- Applicable design standard, safety and zone code documents like state, local, FEMA, and National Fire Protection Association standards

There are many companies who manufacture seismic racks. These racks are built differently than conventional pallet racks, with more ability to resist seismic pressures. This usually means 5″ x 7″ footplates, but can include larger plates and other critical differences in rack design. Since requirements vary so widely, if you are operating in an area that is vulnerable to seismic events, we recommend again that you contact us or another qualified rack supplier to guide you through the process.

You’ve got the right rack correctly installed, now what?

Whether in a seismic zone or not, there are basic pallet rack storage operation factors that should be considered. Properly loading and unloading the rack means you adhere to rack capacities, never overloading beam levels. You maintain the correct beam spacing for the load weights you are storing. Require prompt reporting of collisions, damage or observed deficiencies of the pallet rack. Conduct routine inspections and perform standard maintenance and repair work to keep your pallet rack strong and sturdy.

Fall protection factors

Then go one step further by adding inventory fall protection measures through pallet blocking with stretch wrap or banding. Prevent fall-through of goods with shelf decking such as wire mesh, pallet supports or perforated metal. Avoid using wooden or metal slats, as these may shift during normal loading/unloading operations or during a seismic event, putting inventory at risk. Prevent product from toppling off the pallet rack by using restraining bars, chains, straps or cables, or consider safety netting or wire mesh enclosure panels. You can even add slip/overturn resistant containers to help assure inventory stays in place during the ground motion of an earthquake or forklift colliding with the rack.

Knowledge is power

Finally, see that personnel handling materials or securing materials on or near pallet rack receive training about rack safety and operations. Be sure all vehicle and equipment operators are trained in working around pallet rack. Make sure the people assigned to inspect, maintain and repair pallet rack know what to look for, how to properly maintain and repair rack. It’s just too costly in inventory loss and worker injuries not to.

Tags: seismic, earthquake, fall protection, safety net, wire mesh panel, pallet support, stretch wrap, Pallet Rack, training, wire decking

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.