The Value & Versatility of Rivet Shelving

High capacity storage is economical and easy to install

Rivet shelving is one of the most versatile forms of industrial shelving available. With individual shelf capacities up to 1,400 pounds, it rivals the load capacity of heavy wide span or pallet rack but is designed for carton and case storage. It assembles quickly due to its tear-drop and pin connectors and is extremely sturdy whether using a single-rivet or double-rivet design. It’s also available in an amazing array of sizes and layouts.

Construction is the key to its strength

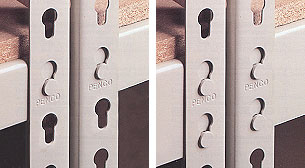

Rivet shelving is made of welded steel posts and shelf beams. The secret behind its sturdy build is in the connectors. The upright posts have tear-drop holes punched at regular intervals, while the shelf beams have button-like connector pins which slide into the tear-drop holes on the posts and, as they fall deeper into the tear-drop, they create a strong hold as gravity pushes the pin against the narrowing tear-drop bottom. This type of connection helps prevent sway and bonds the component parts together, giving the shelving remarkable load capacity and stability.

Shelf capacity that rivals that of pallet rack

Because of the strength of the connection between posts and shelf beams, and the stability created, rivet shelving load capacity is significant. While wider shelves reduce capacity, center supports and more shelves with less beam spacing between shelves can increase capacity, giving you a lot of options in shelf spacing and in optimizing what you can store in the shelving.

Use rivet shelving as the basis for a high-density storage mezzanine

One of the more innovative uses for rivet shelving is to make it the structure for a mezzanine. It can be installed atop a structural platform, but can also serve as the structure for a mezzanine project. This concept provides one of the best concentrated storage areas possible. Due to its inherent versatility, rivet shelving can be cut to exacting heights and installed as support structure to fit any need. This allows you to build a simple square of just about any size, with shelving that runs the entire height, in rows on the floor, and in rows atop the platform. This is often done in auto dealership parts rooms, in warehouses, in work cell areas for manufacturing, and of course in distribution operations.

Often called “deck over” or multilevel shelving solutions, these systems can double (or even triple) available space by using the vertical cube. Since rivet shelving allows unimpeded access from all sides, pickers can add or remove stock from either side of an aisle, on any level of the system. If you work with a qualified company that uses OSHA and UBC/BOCA approved designs, your system will meet or exceed fire codes.

Double Rivet Shelf Capacities

| Shelf Width | Without Center Support | With Center Support |

|---|---|---|

| 36″ | 1,000 | — |

| 42″ | 780 | — |

| 48″ | 750 | 1,400 |

| 60″ | 600 | 1,200 |

| 69″ | 525 | 1,050 |

| 72″ | 500 | 1,000 |

| 84″ | — | 840 |

| 96″ | — | 620 |

Maximum Capacity Per Shelving Unit (lbs)

| Shelf Spacing | Capacity Per Unit |

|---|---|

| 12″ | 6,120 |

| 18″ | 6,080 |

| 24″ | 6,040 |

| 30″ | 5,960 |

| 36″ | 5,400 |

| 42″ | 3,960 |

| 48″ | 3,020 |

Choosing between Single or Double Rivet

While double rivet shelving offers higher load capacities and greater stability, it’s more expensive and takes more of your vertical space up. Double rivet beams are considerably larger than single rivet beams and occupy more vertical space between shelves. However, double rivet shelving has greater lateral stability due to dual rivet connectors on each shelf end. Also, you can specify wider shelving and uninterrupted spans of up to 96″ when you specify double rivet, where single rivet goes up to 48″ wide. If your loads are lighter, single rivet shelving should serve your needs. For larger loads with heavy duty capacities, double rivet is the preferred option.

See Single Rivet vs. Double Rivet for more information.

To deck or not to deck

Wire Decking

Value is in what rivet shelving brings to your storage

With the ease of assembly and disassembly, rivet shelving is an excellent choice when reconfiguration of storage space needs to be easy. Because of its higher load capacities you have open shelving without side bracing, giving you more options in what to store and the sizes of the containers stored.

Learn more:

- Specifying rivet shelving

- Cisco-Eagle’s rivet shelving estimator/layout application

- Submit a rivet shelf inquiry

- Rivet shelf glossary

- Rivet shelving: Penco & Western Pacific

Tags: storage, rivet shelving, Penco, Western Pacific Storage Solutions, carton

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.