Comparing Pallet Rack Frame Protectors

How can you defend rack uprights from forklift and other impacts?

Pallet rack damage can be extremely costly and dangerous. Damaged racks are more likely to collapse or spill their loads, so avoiding that damage is critical.

Day after day, year after year, it’s inevitable that a busy forklift driver in a fast-paced operation will eventually hit a rack upright. I’ve been to many facilities and seen lots of damaged frames, ranging from paint scrapes to twisted steel. This might not cause an immediate collapse, although it can. It does set you up for trouble down the road when another truck impacts the same upright, the rack is overloaded or loaded incorrectly.

Any dented, gouged or twisted rack uprights should be replaced, but how can you avoid that damage in the first place? Let’s examine some common rack protector types and where they might fit for you.

Protecting the ends of a pallet racking row

These guards protect at the end of a single or double row of racks.

Steel guardrails

A variety of steel guard rails can be installed in this role for as much or as little vertical protection as you need. These are the same guardrail systems you might install around an in-plant office, near a wall, along a production line, or around a work cell. They are frequently used in rack protection applications due to their versatility and high visibility. To the human eye, a 42″ tall double rail set against dull green, full rack uprights in a warehouse that might be lit less than optimally are going to be easier to see and may help prevent a collision based on that visibility alone.

Within the guard rail family, there is almost countless variety. You can opt for the traditional steel in a variety of shapes and impact ratings, or flexible poly systems in sizes from 12″ high to nearly 3 feet. All of it helps protect the ends of a rack row.

Rack end guards

Then there are specialized rack-end guards that are built to guard a standard 42″ deep rack. They aren’t as visible as a larger rail, but they’re also bright safety yellow and catch the eye just fine. You install two for a double row. One of the great things is that they wrap around the front column to provide front impact protection, which guard rails don’t. They come standard at 42″ but can be specified for just about any rack depth. They don’t have the height of a guard rail, but let you protect the front and sides of a rack row in one installation.

Both of these alternatives must be bolted to the floor.

Frame/post protectors – myriad options to protect upright frames in a rack aisle

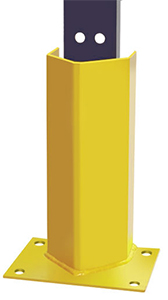

Floor mounted, freestanding steel rack protectors

These are one of the most popular types. They’re mounted on the floor in front of each upright in a rack aisle. These types of rack protectors are extremely common and effective for situations like a forklift backing into an upright, or hitting it with a lowered load on the way to load or unload. They’re also finished safety yellow and are easy to install, remove, or re-use when you need to. They are either 12″ or 18″ high, and are specifically built to protect the most vulnerable part of a rack frame — the base plate and lower leg. They’re economical and durable and much easier and faster to replace than an entire upright.

Since these protectors aren’t attached to the rack, they tend to work well when a floor-level beam is in use.

Attached snap or strap-on rack frame protectors

This is a very different approach than the bolted-down, solid steel presented above. Many companies offer an alternative that attaches directly to the face of the upright frame, but isn’t bolted. These systems don’t try to stop a forklift or pallet when it hits a rack. Instead, attempt to absorb the impact. The idea is that when you hit a bolt-on product, it may damage the floor and be driven into the upright in some situations. Even when it isn’t, you might have to replace the protector and repair the floor. These systems leave the floor untouched and are easier to install. They may absorb enough impact that you don’t have any floor issues in case of an incident, but do not offer the solid steel protection a conventional rack protector does. They can also be adjusted to sit higher on the rack, or even be stacked to offer protection beyond 18″ height.

- Rack Sentry post guards: 18″ tall protectors are attached by a strap to the upright, and can be stacked atop each other to increase coverage.

- Yellowjacket frame protectors: Exceeds FEM 10.2.02 impact testing (Code for protection from damage caused by forklifts or other moving equipment to upright racks). These protectors are 9″ tall and can stack.

- Nashville Wire Snap-On Protectors: Outer walls are crush resistant upon forklift impact through deformation as the impact force carries into the unit. Higher impact forces are further deflected by spreading the force throughout the device’s inner walls. 5.25″ high protectors can be stacked to the desired height. When an impact occurs, replace the affected protectors and leave the rest in place.

Snap-on steel protectors

These protectors offer solid steel to help deflect impact. They are attached to the rack’s teardrop holes and snap into place. You can install them at the floor, or even higher on the rack face if you are concerned with upright damage beyond the floor level area. They can easily be removed, reinstalled or replaced at need. Ideal when you are seeing damage further up the upright than the typical floor level impacts. These guards can be adjusted on 2″ increments, with 4 connectors per guard.

Reinforced Rubber Post Protector

Made from rubber with a U-shaped steel insert, the reinforced rubber post protector can withstand multiple forklift collisions with no damage to the guard or upright, providing long-lasting protection against rack damage. The rubber compound features greater elasticity than other post guard materials, giving it a unique ability to absorb energy and deflect impacts. A great choice for high-traffic settings within your facility, as it is tested for multiple strikes.

More rack protection resources:

- A guide to pallet rack inspections

- Structural vs. Roll-Form: Which Rack Fits Your Application?

- Pallet Racks and Falling Item Prevention

- A Guide to Pallet Rack Load Types

Tags: warehousing, Pallet Rack, Safety & Ergonomics, forklifts, bollards, Rack Protection

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.