OSHA Requirements for Better Loading Dock Fall Protection

How can you make your shipping dock safer?

In warehouses, about 25% of injuries come at or near the loading dock area.

This is usually because it’s such a focal point of any distribution operation—it’s where everything is accepted and put away and where everything eventually processes out. This means that at times the dock will buzz with forklifts, workers on foot and other bursts of activity. It has a natural fall hazard in the edge of the dock. It’s got exposure to elements, meaning that it may have moisture, oils and other trip/slip hazards. When it comes to preventing falls, what are OSHA’s requirements? And what should you do above and beyond them?

Most elevated truck docks are subject to guarding regulations

OSHA 26 CFR2.23 (b) states that any wall openings with more than a four-foot drop should be equipped with a fall protection barrier. Since most docks are at least 44″ tall to serve tractor trailers and flatbeds, a majority will be subject to that requirement. Most standard docks come in about 48″, or close enough that even if you are technically outside the requirement, it’s a good idea to guard the edge. Taller docks, like those required for refrigerated trucks, are always going to fall under the requirement, as they are north of 48″ tall in most every case.

However, the agency also states that if a barrier would prevent the flow of work, that a “visual” barrier is sufficient. However, this is open to interpretation, and it’s a safer bet to install fall protection at these spots. There are compromise solutions such as removable gates and rails, which are covered below.

OSHA Guarding Standard 29 CFR, 1910.76: Covers and/or guard-rails shall be provided to protect personnel from the hazards of open pits, tanks, vats, ditches, etc.

Should you protect dock edges less than 48″ high?

The answer is usually yes.

The functional difference between a person—or in particular a forklift—falling 44 inches and falling 48 inches is nonexistent. Grave injuries are just as possible at 3′ as they are 4′. A good rule of thumb is to guard any fall edge where a forklift could drive off. If people are the issue, look at the height and decide if you think it’s a safe distance. Dock edges are one of the most economical, least difficult areas of a facility to protect, so it’s best to err on the side of caution. Most of the dock gates and rails that are available are easy to install, low-maintenance, easy to operate and economical to purchase. When it comes to safety you aren’t usually pursuing a defined ROI, but fall protection at a ledge that high can offer lifetime dividends compared to even one injury.

Forklifts in particular are notorious for falling from dock edges. If a driver isn’t buckled in (which he always should be), he is at grave risk of severe injuries, or even death.

The big takeaway? Guard most every dock edge.

Some fast tips for guarding your docks:

Keep the doors closed when trucks aren’t parked at the dock

This can become problematic when the facility isn’t climate controlled, and you’d like to let some fresh air in via the doors. It means you have to find other methods to gain a little fresh air. It also does not solve the issue for instances where a dock pit is built inside a facility and no door exists to cover the opening.

It’s also something of an issue to keep those doors closed in a busy operation. Warehouse workers can see incoming trucks easily when the bay doors are open. Also, constantly opening and closing dock doors is a hassle for workers and puts unnecessary wear and tear on door components.

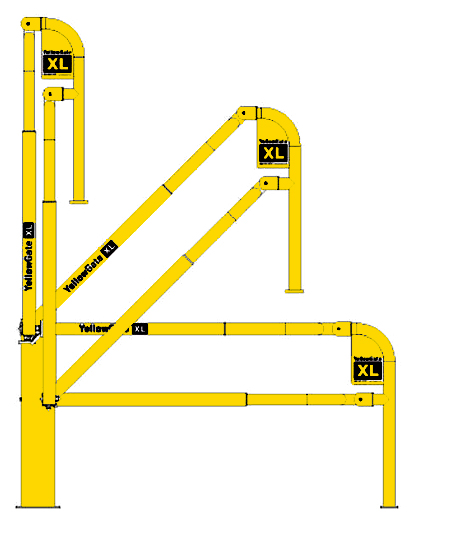

To guard open doors, use dock safety gates that rise or swivel out of the way

There are quite a variety of these types of gates. They range from net systems to solid metal rails that can be moved out of the way either vertically or horizontally. Any barrier you use should be brightly colored. Safety yellow is highly recommended. To be useful, any barrier or gate should be easy and quick to move or remove when work begins. So in the case of gates you have options that may work better for your layout and operation.

There are quite a variety of these types of gates. They range from net systems to solid metal rails that can be moved out of the way either vertically or horizontally. Any barrier you use should be brightly colored. Safety yellow is highly recommended. To be useful, any barrier or gate should be easy and quick to move or remove when work begins. So in the case of gates you have options that may work better for your layout and operation.

- Power or manual? Although some gate types are available powered, most are manual. The majority of gates installed are manual ones, but there are good reasons for power systems. If you cannot convince workers at the dock to use the gate, it may be ignored or even sabotaged. If it easily retracts, rolls off or lifts out of the way, people will be more inclined to take precaution. That’s one good argument for the more expensive motorized gates that can open with a push button, or even be integrated into dock doors or motion sensors.

- What is the gate’s capacity? Most gates are easily able to handle the weight of a person leaning on them, but it’s always good to check on the stress a particular safety barrier can handle.

- How does the gate move? Gates are typically closed whenever the dock doors are open and a truck is not at the dock opening. When dock doors are closed, they can be left up or down depending on your needs. The basic motion ranges are (1) Lift vertically, (2) Cantilever, (3) Swing horizontally. Some gates fold in the middle, meaning they require less space when not fully extended. There are gates that fold in, which are mostly considered for security reasons, but would also be adequate to ward off falls.

- Make sure to take your working environment into account: The gate you specify should not interfere with dock operations. If you use the space to the front or side of the doors, then a gate that swivels into that area may not be helpful as it could interfere with people and equipment in the area. Lifting gates should have adequate vertical clearance for your operation.

- What are you guarding against? Some gates are listed with capacities high enough for forklift fall prevention. Most do not fall into that category and are primarily used as visual barriers, or have capacities high enough only to stop a person from walking through. Lift gate systems, which are anchored to steel uprights inside the dock door, are built for forklift fall prevention, and there are a few others, such as these net gates that also help stop loads from falling, such as boxes or pallets

What is a visual barrier, and when can I use one rather than guarding?

In many circumstances, it can be a simple chain that’s stretched between the sides of the dock door. The barrier should be safety yellow for visibility. It won’t help prevent falls as well as an actual gate or guard rail, but may help satisfy OSHA if you can demonstrate that the presence of a true barrier would impede work. Be careful, as there is ambiguity in the regulations. Also, it’s just safer for people if the edge is guarded when you are at truck dock height or more. If you opt for a visual barrier, make sure it’s easy to engage and remove with easy connectors or magnets.

Don’t let visitors, drivers or others linger in the dock area

It’s never a good idea to have visitors hanging around your facility. People who don’t belong near the shipping dock should not linger there; it isn’t safe for them or your workers. Truck drivers and other visitors should never be allowed into operational areas any longer than necessary. If possible, move them to driver lounges. Extra people in hazardous areas are at greater risk than those trained for to work in those areas. If you have repair people, salespeople or others who aren’t trained in your safety and operational protocols, offer training or escort to be sure they are safe.

Make sure your edges are visible

To help people understand that there is a drop off, it’s a good idea to paint the edge of your dock safety yellow, which is very visible on a gray floor. Some dockplates and dockboards come pre-painted with safety yellow edges.

Final thoughts

Keep state guidelines in mind as you specify solutions. You must satisfy both Federal and State requirements in these situations, and they can vary greatly from state to state. More resources for loading dock safety can be found at these links:

- How to Avoid Loading Dock Injuries

- OSHA: Loading Dock Safety eTool

- How to Cope with Cold Weather at Warehouse Shipping Docks

- Options for Dock Door Access Control

Tags: 3PL, Third Party Logistics, ecommerce

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.