Carousels & Ecommerce

Long utilized, vertical carousels are emerging as efficient storage options in the age of e-commerce

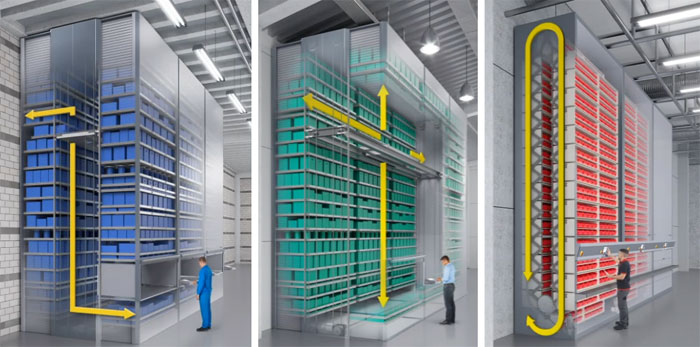

Once an afterthought in the warehouse, vertical carousels are being reborn in the omnichannel age as a fulfillment finish line product. Retailers are eyeing carousels to help them aid in customer retrieval of picked orders shipped to a retail location, which is giving the carousel a “moment” as a new last-mile darling. Whether located in the back of the store for employees to use, or at the front for customers to pick up themselves, vertical carousels are showing to be a good fit for this new age of sales. But don’t sleep on their value in industrial settings or distribution channels.

The attributes that make these systems work for retail e-commerce are great for the warehouse or distribution facility, so how can a vertical carousel help your operations meet customer demands?

Saving space and utilizing the cube

A vertical carousel is a great way to capitalize on unused space while improving warehouse efficiency. The vertical space that would once lie dormant is used to move product. In other words, vertical carousels transform empty air into usable space. To look at it from another angle, consider the benefits gained from freeing up existing space for something other than storage. A vertical carousel offers the same amount of storage as shelving, but in a much smaller footprint, saving floor space — which, in this age of space maximizing and omnichannel, can be worth a lot more than it used to.

Reduce needless movement, recoup wasted time

In any facility, there is a vortex of time spent per employee on extra movements not associated with their exact tasks. With this paradox, we’re always looking at ways to improve the time used every day. Storage and removal time efficiency greatly increases when you invest in vertical carousels. Your workers quickly push the up or down button and have their inventory delivered to belt height. There’s no more time-consuming forklift runs or manual lifting. You save time, and time is money. Automated vertical carousels deliver products right to your workers’ level. No longer do they have to hunt and search while picking products. You can also add barcode item identification into the carousel system for pin-point picking accuracy.

Optimize inventory management

As with time, organization is another huge aspect in a warehouse that can constantly be improved. With that, vertical carousels are excellent for inventory control. Vertically stacked with an automated control system, they let you organize your product flow in a streamlined way. That’s true whether you’re demanding materials for production or safely storing them for future use. Vertical carousels immensely improve your production efficiency. Being organized with automated vertical storage lets your production team efficiently store and pick the products they need, exactly when they need them. There’s no unnecessary product movement and that’s efficient. You can also interface your vertical carousel with your existing warehouse management system for greater accuracy and organization of products.

Another great benefit of implementing a vertical carousel is product protection and safety. The enclosed design means your products are protected from dust and particulates when stored inside, which reduces housekeeping and plant maintenance burdens.

Other resources:

- Space savings through vertical carousels

- Goods-to-picker methods and alternatives

- Questions to ask: carousel picking systems

Tags: vertical carousel, industrial carousels, ecommerce

Evan Fleishacker