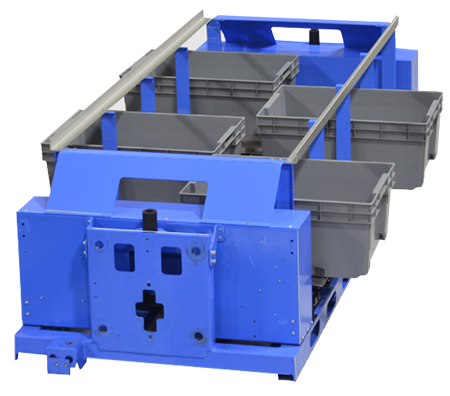

4-Tote Carriage Mini-Load for Small Product Storage & Retrieval

Doubles the storage/retrieval capacity of conventional mini-load systems

Our partners at Murata Machinery USA are introducing the company’s newest addition to its mini-load AS/RS line, the Ledger A3 AS/RS system. This four-tote carriage mini-load system for smaller, lighter goods is the first of its kind.

How the system works

The Ledger A3 loads and unloads up to four totes simultaneously — that’s twice as fast as conventional mini-load AS/RS systems. That speed means throughput of up to 400 totes an hour, which is twice the throughput of single or twin deep mini-load systems. It also delivers high-density storage, with 1.3 times the storage efficiency of conventional mini-load AS/RS. That combination of speed and storage density makes the A3 an ideal solution for e-commerce, distribution and other demanding high-throughput applications.

The system transfers totes individually or simultaneously, providing the kind of storage and accessibility responsiveness modern distribution operations require.

The Ledger A3 operates in small spaces due to its compact shuttle

The system stacks up to four totes simultaneously, maximizing storage density and retrieval speeds. When you need to do more in the same operational space, with fewer people and fewer touchpoints, this kind of higher density, labor-efficient system can help you operate in existing warehouse space while you make plans for future expansions and operational changes.

Above: high-density carriage is twice as fast as conventional storage and retrieval methods because it transfers up to four totes at the same time. It sorts and retrieves various loads with minimum interactions with people or other processes, making AS/RS even more compelling for the right types of operations. When combined with Muratec’s SHUTTLINER, it is an optimized goods-to-person (G2P) system that minimizes manual handling errors and boosts throughput.

Specifications at a glance

- Crane height: 29.5 feet H (maximum)

- Tote size: 13.4″W x 18.9″D x 11″H (maximum)

- Weight capacity: 15.4 pounds per tray (60 pounds per 4-quad carriage)

- Travel speed: 984 feet/minute

- Lift speed: 360 feet/minute

Applications

This system is ideal for any higher-throughput application where smaller goods are stored and retrieved with an emphasis on speed.

- Order fulfillment and distribution centers

- Ecommerce order fulfillment operations

- Food and beverage

- Medical and pharmaceutical

- Cosmetics and related products

The A3 works for almost any type of warehousing where loads fit the system’s specifications.

“In today’s rapidly changing marketplace, consumers are demanding their products immediately, if not sooner,” said Scott Matlock, Murata Machinery USA, General Manager, L&A Division. “This means businesses must react to tighter speed of delivery expectations across manufacturing, warehousing and distribution markets.”

Want to see the system in person? Visit us at ProMat 2023!

The Ledger A3 AS/RS crane is a game-changer for businesses that need high-density storage and retrieval of small, lightweight goods. Its ability to load and unload four totes at once, its compact size, and its integration with Muratec’s SHUTTLINER make it an optimal solution for high-throughput distribution applications.

You can see the innovative carriage live at ProMat 2023 March 20-23 in Chicago, at booth 2703A. We can provide a personal demonstration based on your schedule. To book yours, contact Cisco-Eagle today.

More resources

Download the Cisco-Eagle guide to order picking

When it comes to picking orders, you have many options: equipment types, methods, technologies and more. Download our guide to order picking to read tips and articles from our expert employee-owners. You’ll find practical examples of ways to cope with ergonomics, slow movers, various picking systems and much more.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with more than thirty years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.