What to Do When Your Pallet Rack Storage is Maxed Out

Options to squeeze more storage from your warehouse

If you’ve worked in a warehouse long enough, you know the feeling: pallets everywhere, racks packed to the top beam, and your team playing Tetris just to make the incoming shipment fit. You’re sometimes storing pallets on the floor or holding them in the receiving area until a slot opens. It’s frustrating, destroys organization, slows everything down and ramps up safety risks. What are some things you can do to squeeze more capacity from your warehouse?

When space starts to tighten, what are the warning signs?

Above: What are the signs of space fatigue for a storage facility?

Pallet racking systems rarely scream for help, but the warning signs might be there. Maybe you’re seeing pallets stack up near the docks or sitting in the aisles. Your team might constantly rearrange locations to fit new stock in. Maybe picking errors are climbing or people are spending more time looking for stock.

Some warning signs may include:

- Overflowing aisles or constantly full staging areas

- Frequent inventory reshuffling. You’re always swapping stock positions

- Visible rack strain or safety hazards; people are hitting racks to load or unload

- Worker frustration, especially from your forklift drivers

- Missed shipments or mispicks due to disorganization

- Pallets stored on the floor “temporarily”

You won’t always see the signs as space or storage organizational issues when they manifest. Recognizing them early helps you mitigate space planning and racking issues before they can become dangerous or a significant drag on productivity.

Overloading and mis-loading pallet racks

Sometimes people address this by adding more to their racks than they should. Don’t push beyond your system’s capacity rating just to fit in more pallets. You risk structural failure. That can mean collapsed racks, damaged inventory, worker injury, and liability headaches. When you floor stack, you limit forklift drivers’ room to maneuver and cut into driver visibility, which is dangerous for many reasons. Chief among those is pedestrian safety. But you can also end up with narrower aisles and the potential for rack damage when forklifts swerve around floor stacks and potentially strike an upright or column. This can cause product damage, rack damage or even a dangerous collapse.

Squeezing space by using your existing storage slots more efficiently

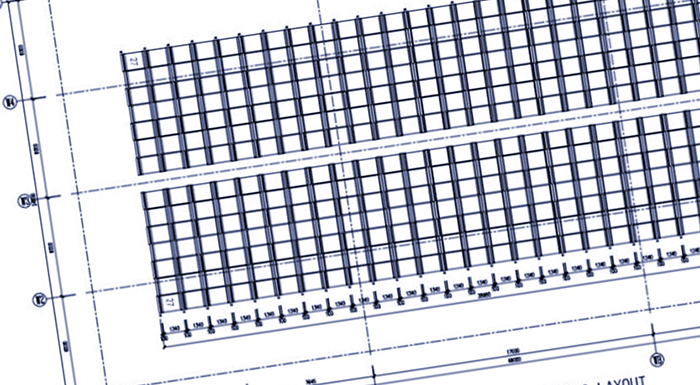

The fastest (and most economical) way to optimize space is using your current rack slots more efficiently. You may have the space, at least for now, in the racks as they’re configured and laid out. Some of those options can include tweaks to how you’re storing things and using the system right now. In the illustration above, you can see that 30-40% of the air space in the rack structure is empty. Sometimes this is unavoidable, but when you can make it work, load consolidation is an extremely effective storage strategy.

- Single cartons are taking up full pallet locations. You’ll see pallet positions full up, and then those with just one carton or a handful for the entire pallet.

- Half-empty pallets are spread across multiple bays. When you see this constantly, you have a load consolidation opportunity.

- SKUs are stored across redundant positions but are infrequently accessed. When you see the same SKU in multiple pallet positions, there may be a better way to use those positions.

By consolidating these loads you can free up space without spending money or reconfiguring your layout. Be sure this is done in conjunction with your WMS or inventory slotting system. Also, don’t violate your own FIFO rules, lot tracking or safety procedures. Be sure your team understands why and how you’re doing it.

Also, consider implementing multi-SKU storage where appropriate. For slow-moving or low-volume products, sharing a pallet position makes more sense than a full pallet slot that’s rarely used. This may increase storage bin complexity, but many inventory systems can split bin positions on a single pallet. You may find that your slower-moving, low-inventory items can double or triple up on a single pallet. Usually, those are lower positions designed for hand-picking carton-pick access.

Don’t overlook dead inventory

Old stock, damaged goods, or items that haven’t moved in a year? Move them out. Liquidate, return, or relocate them to off-site or overflow storage. Every pallet of dead weight you remove creates space for active, revenue-generating inventory. It can be painful to write off stock, but if it’s a constant drag on operations and you can’t see it ever moving, take action.

Deep dive: multi-SKU/shared pallet positions

If you’re storing low-volume SKUs across full pallet positions, you’re not maximizing your rack system. Shared locations or multi-SKU rack slots let you combine several small products into one organized bay. It’s especially effective for spare parts, obsolete, but still necessary SKUs, specialty materials or similar situations. You’ve probably had single customers whose inventory is dedicated solely to them. That’s a prime case for consolidation.

The rules for shared pallet positions

- Make sure your bins are clearly labeled. Anyone who either picks or puts into those positions should be able to understand the situation at a glance.

- Track your positions and sub-locations. Be sure it’s clear and easy to understand at every level.

- Work in tandem with your WMS or your inventory tracking system. When you do this, bring in all the players.

When you take these steps, establish consistent rack labeling, update your WMS regularly, and train your team to follow slotting and consolidation procedures. An organized rack is a productive rack that prevents from slower moving or smaller inventory from eating into prime rack real estate.

Lot storage: It can be ugly, but it’s effective

When you need the stock, but don’t need it easily at hand, container/lot storage comes into play.

If you’re storing bulk stock, seasonal items, or overflow pallets in your racking, consider moving them out to external container storage. This does mean you’ll be storing things outside, assuming you have the parking or staging lot space. If you do, this method can save a ton of space.

Store bulk or seasonal loads in shipping containers

The load and the situation should be suitable. Are containers always a good option? No. But they are relatively inexpensive and easily loaded.

The issue with them is that organization and access can be challenging. Standard shipping containers are 20 or 4o feet long, and typically 8 feet wide. Standard units are 8’6″ high, but high-cube ones are 9’6″. This is a lot of space, but accessing it can be tricky. If you need to pull only part of the storage, you may find yourself loading/unloading it to get to some pallets in the back. The good news is that shipping containers are relatively inexpensive and easy to acquire. They’re built to be stacked, so you can store them vertically.

Trailer or dry van storage

Stage these trailers near your dock. Standard trailers are 53′ long (longer than the largest shipping containers, 8’5″ wide, and 9′ high. They easily hold 45,000 pounds. This adds up to 26 pallets, assuming yours are standard 48″ x 40″. Variations can be smaller (48 or 28 feet long, like pup trailers).

Trailers are more expensive than containers but are larger and more versatile. If you’re concerned about aesthetics outside your facility, they probably look a little better. They’re also relatively easy to move around. You can also back them to your dock when it’s time to access the stored loads.

Outdoor storage

Sometimes, your loads are durable goods that don’t care about exposure to rain, moisture, heat or cold. You can park these things in the lot, either unprotected or stretch-wrapped. Raw materials are sometimes stored this way. While this does expose stock to the elements, when it works it’s basically free. You still have access and organizational issues to deal with by stacking materials outdoors.

This strategy instantly relieves pressure on your rack system—especially during high inventory cycles. All lot storage methods let you focus your storage positions on the most important, most frequently accessed, highest-value inventory. Be certain you take security, safety and accessibility into account when you store inventory outside. Things you don’t need all the time can live in less valuable space than an expensive and constantly needed rack bay.

Other methods and concepts

Sometimes you simply can’t get the space you need without changing your rack hardware and layout. What are some of those considerations?

Revise your layout

This is a big consideration, as it likely means you’ll be installing new racks and moving existing ones around. You can narrow aisle widths, add more beam levels or create higher density zones. You’ll be pulling the warehouse apart and putting it back together in many of these situations. Some resources:

- How to Design Storage Buffers

- Finding Hidden Warehouse Capacity

- How to Measure and Improve Industrial Storage Space Efficiency

Install higher-density storage systems

This means adding dynamic rack systems that let you stay in your current space. The costs can be considerable, but for the right situation, higher-density systems can pay off. Options range from selective racks to double-deep systems to full fledged drive-in, pushback or pallet flow systems.

All have their advantages. Below, Ross lines out the considerations in a short video.

- Evaluation: Pallet Rack Storage Density, Access, Safety and Costs

- Pallet Rack Evaluation: Storage Density

- Selectivity vs. Storage Density: Choosing the Right Pallet Rack for Your Application

Pulling it all together

A crowded rack system doesn’t always mean you’re out of space. You may just need to rethink how to use what you have. From consolidating partial loads and reworking aisle widths to switching rack types or offloading to container storage, there are countless ways to optimize your pallet rack system without breaking the bank or building a new facility.

By focusing on the right SKUs, reconfiguring smartly, and using every inch of rack space purposefully, you can extend the life of your existing warehouse and keep operations moving safely and efficiently.

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.