While the landscape has never been less certain, warehousing and manufacturing professionals must still plan for 2026 and beyond. This post rounds up authorities on what to expect the next few years and how experts advise you to factor in these trends in trade, technology, artificial intelligence and more.

Read the rest of this entry »

Insights March 2026: Strategic Planning for Industrial Operations

Posted in Industry Insights|

The Golden Zone Is a Moving Target: Slotting for High-SKU Warehouses

Warehouse efficiency doesn’t fail all at once. Instead, operations slow down quietly. A few extra steps per order. A little more reaching. More waiting. Congestion forms up when you’re not thinking about it. Over time, the operation becomes heavier, less fluid, and more expensive without anyone noticing exactly when it happened.

In many cases, the cause isn’t labor, effort or faulty equipment. It’s geography.

Posted in Order Picking & Fulfillment|

Why the Best Warehouse Designs Balance Density and Access

Warehouse buildings have been getting taller: what was once a 16 to 18 foot clear-height facility is now commonly 32 to 40 feet. The logic is straightforward: taller buildings unlock more vertical storage, allowing operators to store more product without expanding the footprint. If you’re in an expensive, landlocked area and need more storage, you need to unlock every vertical inch. High bay pallet rack systems let you use all that air space and can massively increase storage density.

This is a good thing. Until it isn’t.

Posted in Pallet & Warehouse Racks|

What to Do When Your Pallet Rack Storage is Maxed Out

If you’ve worked in a warehouse long enough, you know the feeling: pallets everywhere, racks packed to the top beam, and your team playing Tetris just to make the incoming shipment fit. You’re sometimes storing pallets on the floor or holding them in the receiving area until a slot opens. It’s frustrating, destroys organization, slows everything down and ramps up safety risks. What are some things you can do to squeeze more capacity from your warehouse?

Posted in Pallet & Warehouse Racks|

The Easiest Win in Automation: Machine Loading and Unloading

Machine load-unload automation is one of the most profitable and straightforward automation opportunities in both warehouses and factories. It improves productivity in two key ways:

- Reducing labor needs: Repetitive manual loading and unloading is replaced with automation, cutting costs and reducing injury risk.

- Increasing machine uptime: Machines stay productive with predictable cycles, eliminating idle time between parts.

The real payoff is in uptime. When unloading and reloading are automated, a machine rarely waits for an operator. Preparatory work and staging can happen offline, so the next part is always ready. In ideal cases, production rates can increase dramatically without additional equipment investments. Focusing on these key points, where automation can have outsized impact is the key to smarter, better operations. These tend to be low value, but critical processes that should be automated so that labor can be reallocated to more critical functions.

Tags: Automation, Manufacturing

Posted in Automation, Labor & Efficiency|

Insights August 2025: Employee-Ownership & Manufacturing

This month, we discuss strategic warehouse execution system implementations with Savoye–how to scale, how to match real-world processes. Additionally, the impact of employee ownership on manufacturing and its potential as a key to succession for small and mid-sized manufacturers. Also, more on industrial construction and the softening demand for manufactured products.

Read the rest of this entry »

Posted in Industry Insights|

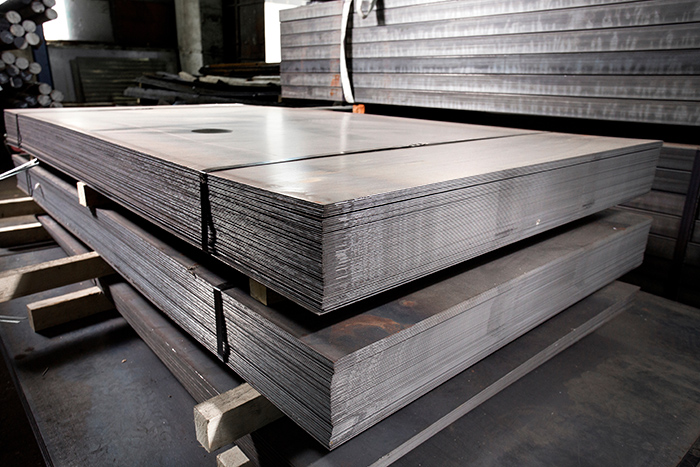

How to Choose the Right Sheet Metal Storage System

Whether you’re running a metal fabrication shop or laser cutting center, or stocking raw materials for manufacturing, sheet metal storage can make you faster. It makes the stock easier to reach, protects valuable materials and prevents injuries. However, the wrong solution means injuries, wasted time and damaged materials. In this article, I’m covering a range of solutions, from simple floor stacking to semi-automated carousels, analyzing for fit, safety, access and cost.

Posted in Manufacturing|

Insights: Labor Balance in an Aging Society

In 2025, the U.S. labor market is undergoing a significant demographic shift. Approximately 4.18 million Americans reach retirement age this year (about 11,400 turn 65 each day). The Bureau of Labor Statistics projects that the labor force will grow at a modest 0.4% annually from 2023 to 2033, reaching 173.3 million by 2033. The problem: we’ll need to fill 192 million job openings, according to the Bipartisan Policy Center.

Posted in Industry Insights|

Cisco-Eagle Announces 2025 Core Values Awards

Cisco-Eagle named its inaugural Core Values award winners in June 2025. These are employee-owners who embody our core values–the principles we aspire to. Those values were established over thirty years ago and remain unchanged since. “They are universal and timeless,” said CEO Darein Gandall. Our founder, Warren Gandall, has often said that he wants to treat his suppliers, customers and employees the way he wants to be treated.

Our values reflect that vision, and so do the 2025 winners of these awards.

Posted in ESOP & Company News|

Best Practices for Loading & Unloading Pallet Conveyors with Forklifts

Loading and unloading pallet conveyors with forklifts is an everyday, all-day task.

Done right, it’s fast and efficient. Done wrong, product damage, collisions, injuries, and workflow bottlenecks happen. I’ve seen it in dozens of warehouses, even in highly automated operations, and most of them tend to bridge the shipping dock and the end conveyor lines with forklifts (these days, AGVs and AMRs often do this work). Pallets are large, heavy and in motion when they’re transported on conveyors. That combination of size, pressure and movement can result in damage or injuries when not properly controlled.

Tags: forklifts, conveyor safety

Posted in Conveyor Optimization|