Gravity Conveyors and Product Flow

Consistent load movement is a matter of load and angle

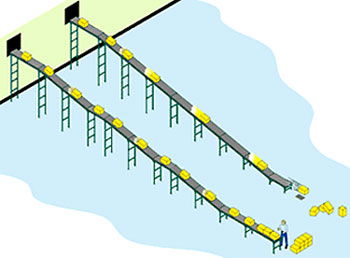

Install Gravity conveyors on declines so that the infeed side sits higher than the end of the line for smooth product flow. This is one of the easiest ways to move products quickly and economically. How can you set up your gravity conveyor for optimal product flow?

Factors for product flow

Speed and flow

- Infeed and discharge elevations: These are the fundamental heights of the conveyor at the top (where product enters) and bottom (where the product stops). The steeper this slope, the faster product can flow.

- The acceleration effect: The acceleration effect of spinning roller or wheel that’s still moving after a preceding box has rolled across it affects flow speeds.

- Flow design: Boxes and other loads move faster in straight lines. Adding curves or turns reduces flow.

- Speed: too fast, too slow If your conveyor flows a little too well, you can adjust the pitch or use retarding plates to manage roll speeds. You can also add end stops for managing the end of the line. if the conveyor flows slowly, you can increase slope angle to speed things up.

Conveyor type and specifications

- Conveyor type (roller or skatewheel): Items flow faster on skatewheel than they do on gravity roller conveyors. Rollers work better for poor loads and more types of loads.

- Are bearings grease-packed or clean? Grease packed bearings tend to roll slower.

- Load weight: Specifying conveyors so that they fit the weight of your load promotes good product flow. Rule of thumb is that the same type of load, on the same conveyor, at the same slope, will move faster when it’s heavier. Some very light loads will not move at all. Some very heavy loads may move too fast. A tote that weighs 10 pounds requires more slope than one that weighs 50 pounds.

- Line length: Cartons may accelerate on longer runs. Make sure they don’t move too fast for the operation or end of line process.

Load characteristics

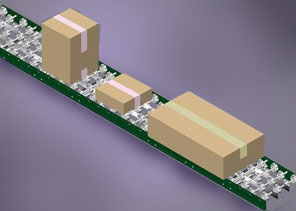

Firm, smooth loads flow better. Difficult loads tend to require rollers, and move slower. Very difficult loads–saggy, damaged, or inconsistent– are harder to convey. A firm carton conveys differently than a tote of the same weight, placed on the same slope. The differences are more pronounced when load bottoms aren’t consistent, rigid or easy to convey. Bags or other loads with irregular conveying surface will be harder to move than any smooth or rigid surface.

Test conveyor slope before operation

Always test product flow and slope before you begin using the conveyor. It’s relatively easy to adjust pitch before the conveyor goes into operation and you’re dealing with live loads. Be sure you know the largest/smallest, lightest/heaviest load you’ll be conveying.

Gravity skatewheel conveyors vs. gravity roller conveyors

Pitch, angle and speed

- Skatewheels need less pitch to convey the product in a decline situation than rollers.

- Lightweight loads and empty cartons flow easier on the skatewheel conveyor because it takes less force to start several wheels in motion than a roller.

- Skatewheels flow faster because they require less energy to move the load.

Skatewheels help maintain product orientation

Due to the natural differential action of skatewheel conveyors, conveyed products better maintain orientation while moving. This is especially desirable if the product moves around a curved section. As the load negotiates the curve, the skatewheels provide this differential action just as a tapered roller curve. Because each wheel turns independently, skatewheel conveyor is excellent for curves in a conveyor line.

Roller conveyors handle a much larger variety of loads and load types than skatewheels

Drums, pails, and products with uneven or irregular bottoms don’t convey well on skatewheel conveyor — for those, specify rollers. Skatewheel loads need a smooth, solid and flat surface. Because they use plain ball bearings, use skatewheel conveyors should in clean, dry, dust-free environments.

Drums, pails, and products with uneven or irregular bottoms don’t convey well on skatewheel conveyor — for those, specify rollers. Skatewheel loads need a smooth, solid and flat surface. Because they use plain ball bearings, use skatewheel conveyors should in clean, dry, dust-free environments.

Product type and size

Consider product size and characteristics when you specify gravity conveying systems

- Skatewheels require 3 axles and 10 wheels under the product bottom at all times.

- You’ll need at least 3 rollers beneath any load to properly flow and support it.

- Skatewheel is lighter duty and generally used in light duty installations.

- Rollers handle heavier, irregular loads. Check your load vs. the conveyor’s listed capacity.

- Skatewheels extend above the conveyor frame to permit loads to overhang the sides, Don’t allow the width of the load to exceed the conveyor width by more than 25%.

More information

- Read our full Guide to Gravity Conveyors

- Product specifications: Straight & curve gravity conveyors

- Product specifications: Flexible roller and flexible skatewheel systems

Video: a guide to skatewheel selection

Tags: Roller Conveyors, shipping docks, skate wheel conveyors

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.