The Impact Of Industrial Robots On Your Workforce

Robotics are poised to enter the next decade as an increasing workforce, so what will that offer your facility?

A research paper was released last month by two Harvard labor economists highlighted one of the coming decade’s most interesting talking points: the automated labor of the future. We are no strangers to the unique opportunities that adding robots can provide. What this paper sought to do was estimate the current effect of the introduction of robots on wages and employment, while also focus on the future they pose in industrial and manufacturing economies.

With this kind of research being conducted (with many more studies to be revealed for sure) and a spotlight put on the future robotic workforce, many with facilities that could use their services would be wise to discover how they can benefit. But what, exactly, should you be looking for?

Robotics is becoming a workforce fixture, with nearly 1 million units forecasted annually by 2022. This shows that they will continue to perform more industrial functions in the near future, but what does that mean for operations in your facility?

Cost savings

While the prevailing perception that robotics is not needed or too expensive still lingers, this attitude is weakening as each year progresses. The costs for robotic automation systems in a warehouse have kept a steady constant, while many of the other automated equipment you could invest in has steadily climbed for the past decade.

Typically, there are two major costs to warehouse robotics you need to consider: implementation and the monthly system lease. Early adopters have shown that once the fully loaded hourly labor cost reaches $15 to $16, robotics can be cost justified. They work longer without needing breaks and can run from 12 to 14 hours on a charge. As labor availability becomes tighter and wages push up, more companies will find a profitable application.

Dependable workforce

As mentioned above robotics can provide you with a skilled labor force in a current environment where it seems difficult to retain good quality workers. The initial investment will seem steep, but in relation to the time spent on the hiring and training process, not to mention the incentives it takes to keep those superstar employees, your savings can start to accumulate very soon.

As mentioned above robotics can provide you with a skilled labor force in a current environment where it seems difficult to retain good quality workers. The initial investment will seem steep, but in relation to the time spent on the hiring and training process, not to mention the incentives it takes to keep those superstar employees, your savings can start to accumulate very soon.

It’s never been harder to find skilled employees that you can retain, and with robotic labor, you don’t have to worry about finding or filling those shoes. Low unemployment rates across the U.S. highlights just how difficult it is for a manufacturing or distribution company to grow and thrive if they are highly dependent on labor.

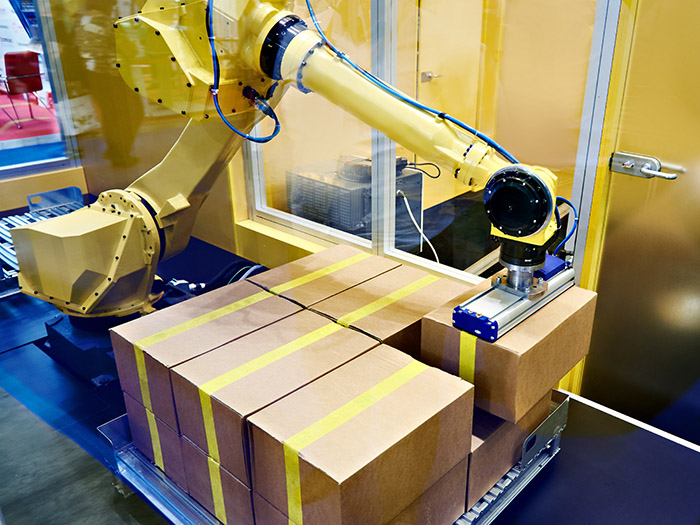

Great teammates

Many companies, including in e-commerce, are using warehouse robotics in collaboration with employees. The best example is in picking. Studies show that pickers in large warehouses may walk as much as 14-15 miles per day, with about 75% of day spent in travel time. Robots travel between zones, while employees generally stay within a pick zone. In the right environment, the addition of warehouse robotics can significantly increase pick rates and decrease the time spent in transit.

Increased flexibility

Your robotic workforce not only can keep on the job for as long as you need them to, but they can also move into different positions and different areas of your facility. In lieu of wondering if an employee will retain new training or a new setting, programming a robot for a different task gives them immense flexibility whose only limitation is the number of tasks you want to give them.

Another realm of flexibility is that newer versions of programming and robotic equipment themselves will continue to be released each year and will continue to be more affordable as time goes on, which makes it easier to imagine an automated labor pool that you can work with now and in the future.

More resources:

- Warehouse Robotics – How to Apply Them to Your Needs

- Planning the Future of Your Warehousing Operation: Don’t be Left Behind

- So You’ve Decided To Automate Your Facility. What Next?

Evan Fleishacker