HVLS Fans, Air Flow and High-Bay Warehouse Racks

Big Ass fans make workers more comfortable -- but often can't be installed above tall rack systems

HVLS fans are an ideal way to make warehouses and other industrial facilities more comfortable and reduce the cost of air conditioning, but they usually can’t be installed above pallet racks, which dominate the floor spaces of most warehouses.

The obstructions

Although pallet racks are the most common air flow obstructions, other issues may also make it difficult to use HVLS systems in certain areas of a facility. Those include ceiling height, electrical issues, ducts, sprinklers, pipes and other large equipment or walls.

Rack rows don’t allow the air to flow as well as open spaces, so other means are needed to circulate air between aisles. Even if you have the vertical space above a rack system to hang a fan, the racks themselves may trap the air.

Airflow between rows isn’t typically as much of an issue as in more commonly-trafficked areas such as receiving and shipping areas, pick zones, work cells, and similar places where people frequently work. If people aren’t spending a lot of time in a row, it may not require circulation directly. However, direct comfort in the rows may not be the only factor, since “still air” may not adequately mix for ideal temperature control and flow when left to sit in these areas.

What about air-conditioned facilities?

Within climate controlled warehouses, it’s still usually difficult for chilled air to make its way between aisles.

Even if traffic between those aisles is fairly low, the air between them is likely going to be less mixed, hotter and less comfortable than air in open spaces where ductwork efficiently distributes it. This makes your HVAC system work harder than it should have to in a large, empty space. Finding ways to effectively mix the air isn’t just about the comfort level between aisles. It directly affects HVAC efficiency and costs.

Read more: How HVLS Fans Make Warehouse Air Conditioning More Efficient

The solutions

Because they move large quantities of air, HVLS fans don’t have to hang over every square foot of a warehouse space to be effective. Generally, they can be mounted over clear spaces like the shipping/receiving area and still push air elsewhere.

Directional fans

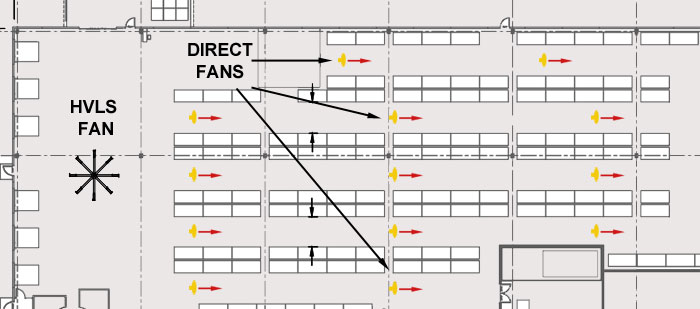

It’s best to map the layout of a fan system to ensure you have enough fans to cover the physical space. In the drawing above, a single fan near the shipping dock pushes air to the floor and down the aisles. Directional fans are mounted to pull that air throughout the system and create the necessary airflow. These fans can be installed on building columns, rack uprights or ceiling supports, depending on facility and site factors.

These fans can be outfitted with motion sensors that allow you to run them only while there is activity in the aisle, so those infrequently-used aisles can still be outfitted for circulation, but the fans don’t have to run when aisles are empty.

A combination of HVLS fans, directional fans and/or thermal equalizers will distribute air throughout a large distribution facility, increasing comfort even in deep rack aisles where air struggles to circulate

Thermal equalizers

There are also excellent options available with thermal equalizing fans, which push air from the ceiling down to the floor to create a constant flow. Unlike HVLS systems, these fans can hang between rack rows and mix air directly above the pallet rack. Combined with an HVLS system, they help move air through the “canyons” between high-density storage rack aisles.

More resources

- In Tight Labor Markets, How Can Warehouses Thrive?

- How Heat Saps Warehouse Productivity, Causes Errors and Reduces Retention

- How to Justify HVLS Fan Systems

The next step

If you operate a large warehouse with deep rack aisles, you’ll probably need to have an airflow strategy that deals with tall rack aisles and stale air. We can assist you with a free layout that moves air correctly and makes the entire warehouse more comfortable and efficient.

Tags: temperature comfort, labor shortage

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.