Insights: Warehouse Ergonomics, Driver Detention, Ransomware Risks

November 2024 Insights

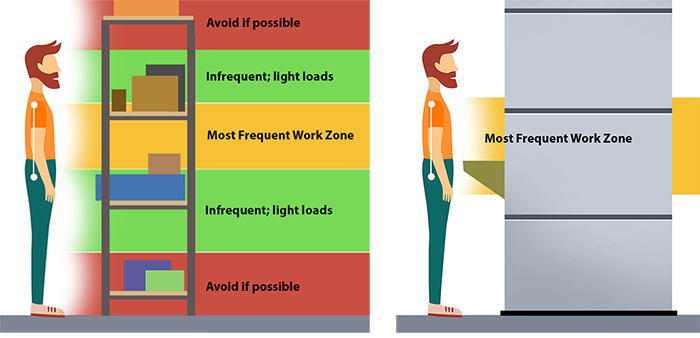

Ergonomics are critical for warehousing and manufacturing operations for both safety and efficiency reasons. North Carolina State University is offering a December 2024 workshop for companies who want to educate themselves on the process. We also cover the impact of slow receiving operations and the impact “driver detention” has on companies and safety.

North Carolina State University Center for Ergonomics offers Industrial Ergonomics Process Workshop

The NC State University Ergonomics Center is conducting an Industrial Ergonomics Process Workshop on December 10, 2024 in Charlotte. According to the University website, “this comprehensive workshop guides participants through each facet of the cyclic ergonomics process from basic ergonomics principles through control development and workstation design guidelines. This workshop meets the objectives of the OSHA #2255 Principles of Ergonomics course.” This is an on-site workshop, over 3 days and provides 3.0 hours of continuing education credits.

The center helps companies build world-class ergonomics programs with training, resources and research functions. It provides industrial risk assessments for industrial operations as part of its mission.

More on industrial ergonomics

- Ergonomics and Pallet Handling

- Improve Productivity with Ergonomic Storage System Design

- How to Use Conveyors to Increase Warehouse Ergonomics

Inbound Logistics: Understanding the Impact of Truck Driver Detention

The magazine details the issues with truck driver detention at warehouses. This is an issue not just for your warehouse, but for the entire supply chain and potentially for public safety. The article cites American Transport Research Institute research, which provides these key takeaways:

Key takeaways

- Truck detention is costly, for both shipping lines and warehouses.

- Drivers are dissatisfied and stressed when detained for long periods of time.

- Supply chains will be disrupted by the overall delays in the system caused by inefficiencies at the truck dock.

- Safety is impacted because delays cause drivers to extend hours on the road. They may feel pressured to speed to make up for the lost time. In fact, GPS data reveals that drivers drive 14% faster than at other times.

What causes truck driver detention?

Drivers are kept at warehouses due to a variety of systematic reasons. There are days when your receiving capacity may be inadequate for the flow of business. If this is a common occurrence, look for the root causes. Those reasons often break into planning problems, communications, equipment malfunctions, volume fluctuations and administrative delays. Consider door availability. Do you have enough doors for the planned shipments, and are they available and staffed?

Recommended technologies for reducing driver delays and detentions can include real-time tracking systems, predictive analytics, automated alerts, digital documentation and collaborative platforms. Other considerations include using that data for staffing at peak hours to receive and unload trucks faster. Making sure your docks are in working order ahead of peak season is also recommended.

More on docks and shipping

- How to Help Drivers Park Faster & Safer at Your Truck Docks

- OSHA Requirements for Better Loading Dock Fall Protection

- How Dock Operations Improve Customer Service

Quick hits

- Manufacturers are the most targeted ransomware sector: In its annual ransomware report, Zscaler Shows a Nearly 40% Increase in Global Ransomware Attacks: This threat is most directly felt in the United States. Manufacturing suffers the brunt with about 15% of total ransomware attacks.

- American manufacturing continues to cut ties with China: This Visual Capitalist infographic delves into dwindling direct Chinese foreign direct investment. As tensions between the United States and China increase, American investment is on a steep decline. American due diligence has advised against Chinese investment in this era. At its peak in 2021, investment was $344 billion. It fell to just $15 billion in 2023.

- How will we staff manufacturing growth in the United States? Aerospace Manufacturing and Design covers the topic of Gen Z is getting the message on manufacturing in a recent piece. The article covers a n ARC survey that 83% of Gen Z respondents would consider trade jobs, with 46% indicating a manufacturing preference. 79% of Gen Z wants to see manufacturing to return to American shores.

Tags: ergonomics, loading docks

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.