write an introduction for this article

Tags: Automation, shipping, labor

Posted in Industry Insights|

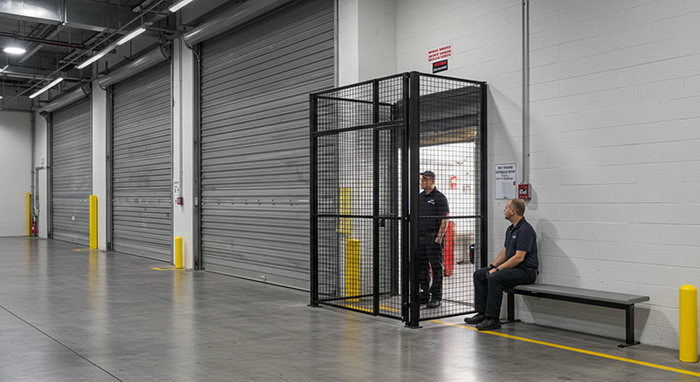

Truck drivers often need to enter warehouses when they deliver or pick up shipments. When they do, many warehouses have installed secure driver cages that let the driver into the facility, but not into the building at large. This can seem “driver-unfriendly” because they contain the driver. However, there are good reasons to install them while ensuring drivers have a good experience at your facility.

Tags: warehousing, dock security

Posted in Docks & Shipping|

Most pallet rack systems are installed with a starter-adder design, which shares a common rack upright between consecutive storage bays. The alternative is a double-post rack system, where each bay has two independent uprights. Most of the time, starter-adder is used because it’s more economical and uses space more efficiently.

Given that it’s costlier and uses more space, why–and where–would you use a double-post design?

Posted in Pallet & Warehouse Racks|