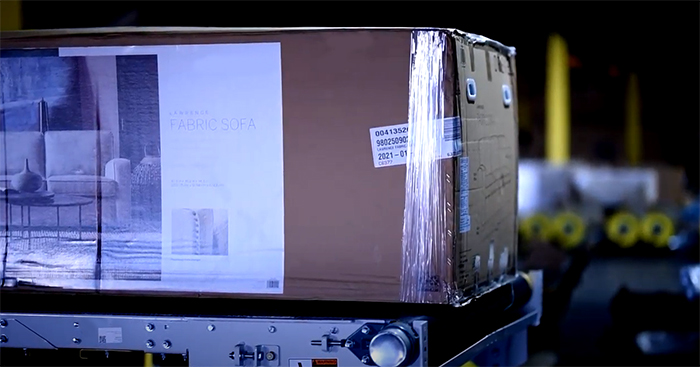

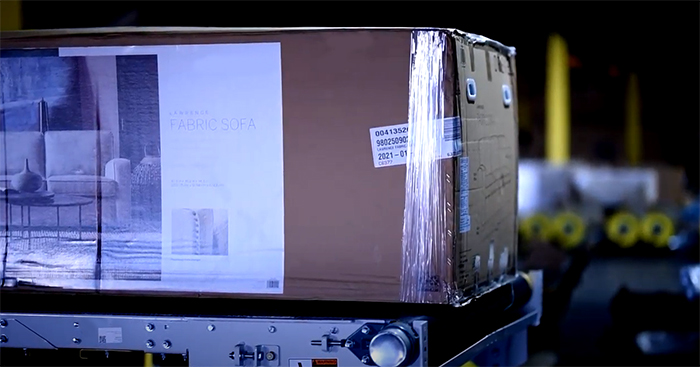

The demand for high-throughput, accurate order fulfillment isn’t only about sorting cartons, parcels and other relatively small, light packages. Large, bulky, heavy items are also in high demand and must be quickly picked, sorted and shipped.

The demand for high-throughput, accurate order fulfillment isn’t only about sorting cartons, parcels and other relatively small, light packages. Large, bulky, heavy items are also in high demand and must be quickly picked, sorted and shipped.

Posted in Conveyor Optimization|

Pallet racks are integral to modern warehousing and aren’t static systems. Safety has always been one of the most critical aspects of warehousing and pallet racks have an outsized influence on warehouse safety. When you evaluate your rack, always take time to look for safety issues.

Tags: Safety & Ergonomics

Posted in Pallet & Warehouse Racks|

Manufacturing plants, warehouses and other industrial operations are all facing one central challenge today: labor shortages. There are other challenges in supply chains, material inputs and environmental situations, but everyone in every industry across the board is dealing with labor—or the lack of it.

Tags: labor

Posted in Automation, Labor & Efficiency|

One of the most exciting things about today’s automation is that it’s becoming increasingly specialized; like eating from a buffet, you can choose what you want. That’s the idea behind cobot palletizers that zero in on a specific target: lighter weight, end-of-line carton palletizing that used to take high six figures and months of implementation time. The critical part of any palletizing project, of course, is the end effector.

Tags: palletizing, ergonomics

Posted in Automation, Labor & Efficiency|

Rooftop safety is an often overlooked area for any facility when it comes to keeping workers protected. In the past, there was minimal equipment designed for this purpose and limited education/training.

OSHA issued a recent ruling on walking/working surfaces, which stressed the need for fall protection for those surfaces (29 CFR 1910 Subparts D&I). This may be significant for a number of operations and the way you protect people who work in these areas. Particularly if you have a rooftop edge or other potentially unguarded platform where people may work, there are steps you should take.

Posted in Safety & Ergonomics|

Posted in Conveyor Optimization|

We spoke with Eric Dodd, who manages Cisco-Eagle’s Field Services Group. Eric’s expertise when it comes to conveyors – and how to keep them running tip-top – is unparalleled. Eric and the Field Services group maintains many miles of conveyors from virtually every manufacturer, in just about every environment. Here’s what he had to say.

Tags: ROI

Posted in Conveyor Optimization|

Space utilization has always been important, but in today’s environment of tight real estate, materials and labor, it’s critical to efficiently use every last inch of your space. Industrial space is in high demand, so finding ways to squeeze more from your pallet rack system is more important than ever. Is underutilized square footage is hiding in your rack system?

Tags: Space Optimization

Posted in Pallet & Warehouse Racks|

Above: distribution center worker stretches over a conveyor line to access a package. Automation can reduce or eliminate this type of stressful, repetitive motion.

Companies tend to focus on the hard-dollar ROI when they evaluate automation—labor reduction, throughput improvements, error reduction and efficiency—but should also consider “soft” benefits like ergonomics, safety and flexibility. Ergonomics in particular should be considered a primary factor in an era of aging labor and tight supply.

Tags: ergonomics

Posted in Automation, Labor & Efficiency|

Above: urethane rollers used on an incline distribution application.

Roller conveyors are galvanized steel, and are sleeved in urethane for specific applications. These rollers can be used almost anywhere and are often specified for food & beverage, printing, automotive and medical/pharmaceutical operations. When should your conveyor utilize urethane rollers?

Posted in Conveyor Optimization|