For 3PLs, Flexibility is a Critical Business Goal

3PLs that embrace cultural flexibility strengthen their operations, their ability to take in new business, and satisfy customers

3PL companies operate in an environment that demands rapid changes and requires continual evolution.

Client requirements can change in a week (or less). New business opportunities can spring up that were unanticipated a month before. From my days working for a 3PL, I know that the ability to swiftly change in order to satisfy both your customer’s increasing demands and those of an industry that never rests were a top priority. The problem? That’s easy to understand, but hard to do.

By understanding the rewards from flexible operations, you can improve multiple aspects of your warehouse. You respond much faster to client demands, new SKU’s, and provide superior order fulfillment for your customers.

Focusing on the rewards of 3PL Flexibility

In the ever-changing logistics business, customers choose their warehousing partners based on flexibility, even if they don’t list that as a key decision point. They want a partner whose warehouse can handle their current business, and any new business from an acquisition, new product lines, or expansions without creating major waves in their supply chain. 3PL’s that dare unwilling or unable to adapt and restructure within the shifts in commerce cannot attract new customers – or even retain current ones who need that adaptability.

This flexibility should apply to all aspects of managing a 3PL. Showing that you are ready and willing to adapt to new technology, storage innovation, time management and operational efficiency offer opportunities to update your offerings and strengthen your business.

Consider new technologies

Whether embracing new automation or conveyor systems to guide the flow of your supply chain, or engaging in new software to help improve and update worker efficiency, updating the technology utilized in your 3PL warehouse can yield results you can see and share. Demonstrating to potential clients that you can store, pick, pack or ship better than those who rely on manual processes is critical. Aside from that, technologies that let you store more, move it better, and produce results help you reduce your labor usage and costs, which feeds the bottom line.

Take advantage of every square inch

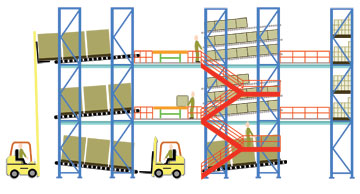

Improving storage efficiency saves time and space, both of which help you respond to new business or expand existing business much more fluidly and at a great advantage vs. competitors. Structural support systems like mezzanines are useful for adding more storage space. With a mezzanine, you can create extra space in your plant quickly, and at a significant savings compared to new construction or expansions.

Also, consider pick modules, which integrate high density storage, conveyors, work platforms and flow systems.

The big takeaway here is that having multilevel storage in an existing facility allows you to take advantage of that space for new business, expanded SKU’s, or new programs that your customers might require. Rather than building out or leasing new space to meet those needs, finding space in your existing footprint is the most profitable and efficient alternative.

Of course, doing things like using the right rack design, one that takes full advantage of your facility design and its vertical cube can also pay dividends. Those extra pallet positions turn into cash quickly when you have them available at the right time, in the right place.

Related articles: “The Most Useless Space in Your Warehouse” | “How to Measure and Improve Industrial Storage Efficiency”

Manage time better. Much better

Tracking metrics and adding structures to your warehouse to help reduce time expenditures demonstrates that you understand what’s important to your clients. To them, you are now part of customer service, and you should package your company’s ability to manage time and return it as clients as part of your business approach.

After all, as we have discussed before, Warehousing and Distribution are a War for Time.

It could be processes, as we highlight above. It can also be technologies, such as light directed pick systems that help you place, pick, and ship faster than your competitors.

Final thoughts

These and many other improvements to your warehouse can allow you to exhibit to potential clients that you know how to modernize and thrive within a vastly fluctuating industry. Embrace change and you can reap the rewards of flexibility.

For more information on how Cisco-Eagle can help your 3PL, visit cisco-eagle.com/3PL

Tags: warehouse flow, 3PL, logistics, mezzanine, warehouse, ROI, Third Party Logistics, time management, time saving, flexibility

Evan Fleishacker