How to Specify Dock Area Pallet Racks

Storage over, near and around busy shipping docks must be carefully planned and implemented

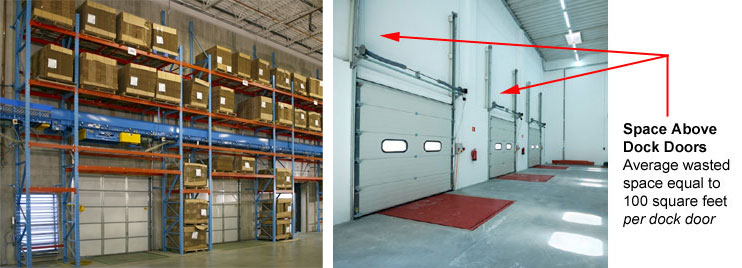

Above: pallet racks are installed both to the side and in front of dock doors in tight space. Palletized loads are floor-staged nearby, further squeezing space.

Warehouse shipping docks are one of the busiest areas in any warehouse. You have the buzz of constant activity as shipments are received or processed out the door, with a mixture of people on foot, forklifts, carts, floor scales, pallets and storage areas. There may be extendable conveyors or other equipment in the same relatively compact footprint. During busy times, it gets more congested and less workable.

It’s also a popular area for palletized storage on, near and around the area. Here’s what to keep in mind:

Placement is critical

The way you place racks, pallets and loads has direct impacts on the safety and efficiency of a shipping dock. Many companies operate with an extremely clear footprint to allow shipping and receiving to take place without worrying about palletized storage, but that’s not always possible. We advise companies to reduce or eliminate “mixed use” zones, where people and industrial traffic aren’t allowed to mix, but again: not always possible.

- When you place racks near docks, always consider the impact on traffic flow.

- Perpendicular rack rows placed close to dock doors increase storage density and reduce dock area traffic flow.

- Pallets on the floor in adjacent staging areas act the same way – but reduce visibility.

- Racks over the doors don’t necessarily impact traffic and shipping/receiving flow, but consume areas used for working, scales, etc.

Placing racks near the dock is always going to result in a tradeoff: you’ll be using space for storage that could otherwise be used for loading, unloading, inspection, processing or other functions.

Focus on safety issues

Because dock areas are among the most dangerous areas in any warehouse, introducing any element that reduces visibility can be a problem. People and industrial traffic frequently mix in some of the most cluttered, fastest-paced areas of any warehouse. Forklift drivers need clear sight lines to avoid collisions with people or structural elements, which is a compelling reason to limit storage near and around dock areas.

Concerns with over-dock rack storage

The “void” above dock doors can be used for pallet storage. It’s ideal because it is the kind of space that usually cannot be useful for any other function, but also brings a rack structure into a high-traffic zone where people and forklifts frequently interact. What are things you should consider when you utilize this space?

- What are you storing? These systems are frequently used to store empty pallets, but aren’t limited to that. They work for large, light loads but aren’t recommended for heavy pallet or unit storage. Consider them “auxiliary” storage with a specific purpose.

- How will you access the loaded materials? Whether it’s to pull or store, the process must be defined. Typically over-dock racks aren’t accessed during the most difficult times – when trucks are at the docks. Even so, when will they be accessed? Never allow people nearby to work beneath while the rack is being loaded or unloaded.

- What is the capacity? These racks may be built with similar components but aren’t meant to store heavy bulk loads. When the first storage level is directly over the door, you have little margin for error. Typical installations may require ties to building structure for this type of rack, but a qualified engineer must make that call.

- How are you protecting the rack? All racks should be installed correctly, bolted to the ground correctly and shielded from forklift impacts. That’s doubly true for over-dock systems, where space is tighter, people more frequently nearby and where forklifts lack as much maneuvering area. Read more: Comparing Pallet Rack Frame Protectors.

- How are you protecting dock workers? Because pallet loads are stored overhead this is a particularly strong area for fall protection systems such as safety nets or wire rack back protectors. Falling items are a problem when people frequently work near and around a rack system – and this is one of the busiest areas in most warehouses. Read more: Falling Item Prevention for Pallet Racks.

- What’s the cost of this space? While you gain space above the door, uprights on the floor will consume some on the floor. Keep that in mind as you specify a dock racking solution.

Floor staging and visibility

If you have nearby, floor-staged pallets, designate an exclusion zone around them once they’re placed. Ideally, this means that you unload a batch for staging and keep foot traffic away from that zone until the lift trucks have left the area. This can be awkward, as pallets are often accessed by your teams in staging while forklifts are still pulling them off a truck during receiving. Because these pallets can be the height of an average person, they obscure drivers’ vision in and around them.

Tall, palletized loads in and near walkways should never be the case.

If you must continue to mix people and trucks in staging, have a defined set of rules for the safety of everyone involved. Keep visitors like truck drivers away from the docks during this phase, but particularly near storage areas. That’s both a safety and security problem.

Read more: Forklift-Pedestrian Safety: Docks, Shipping and Receiving Areas

Rack tunnels near docks

Rack tunnels are “fast lanes” for forklifts

In a busy shipping operation, rack tunnels are often used to allow a forklift to quickly take pallets from a parked trailer and move to the back side of a large distribution center. This can dramatically increase unloading speed. It also works for shipping as pallets in far away storage positions can run from the back of the building to the front unimpeded.

Remember: that people should never use these tunnel lanes. They’re designed for fast forklift movement, so keep humans clear at all times. When forklifts emerge into a dock area, you may need to install safety sensors, speed bumps or controls to slow the forklift down as it approaches the pedestrian-heavy dock area. As you can see in the photo above, a driver in the tunnel will be blind to who could be walking across their field of vision left or right from any lane or dock area.

One approach is to “gate” the areas during particularly busy times so that people cannot cross the forklift’s field of use. This allows forklifts to travel faster with some assurance that nobody will unexpectedly step into their path.

Read more: The Case for a “Supersized” Receiving Area in Your Warehouse

It’s about utility and safety

Storage in and around storage docks has always been a balance of space efficiency, safety and dock operations. Finding that balance for your operation lets you satisfy all these concerns.

Download our Pallet Rack Guide

Pallet rack enhances your warehouse and improves overall facility performance when correctly specified, laid out and installed for the right load in the right positions. Check out our guide to specifications, styles, accessories and applications with expert tips from our employee-owners.

You’ll find quick, useful information on racks and how you can use them more effectively.

Download the guide today

Tags: Receiving, forklift safety, shipping docks, loading dock safety

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.