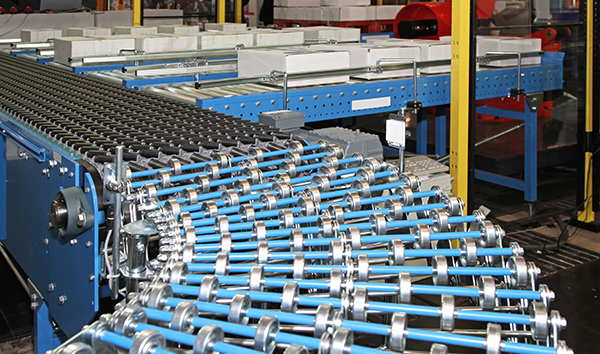

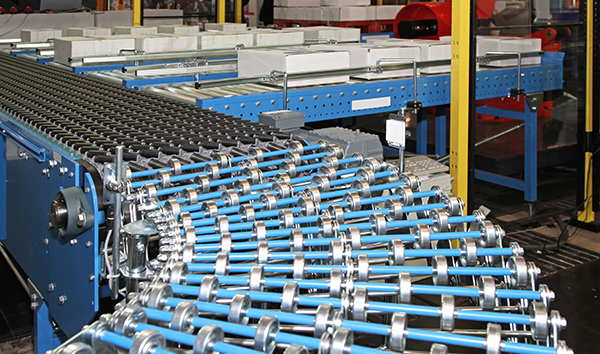

Gravity skate wheel conveyor is probably the most economical conveyor option around for quick, portable movement of lightweight boxes, totes, or trays.

You see it used in shipping & receiving areas, in assembly operations, or as a transitional piece between workstations and powered conveyor lines. You can even slap casters on it for a conveyor that can be rolled in & out of use areas. We even plug it into gravity flow racks to create heavier-duty, FIFO flow storage.

For such a simple piece of conveying equipment — in fact the simplest — errors can and do crop up when it’s ordered incorrectly.

Read the rest of this entry »