This short video details some common-sense tactics for safer pallet rack operations. Remember, pallet racks are designed for specific capacities and loads. If you are working on a rack application and aren’t sure of any of your load factors, contact us for assistance today. Also see our related infographic: “Safer Rack Operations”.

Video: Tips for Safer Pallet Rack Operations

Tags: warehousing, Safety & Ergonomics, Video

Posted in Pallet & Warehouse Racks|

The Fundamentals: High Profile Span-Track Carton Flow Tracks

What is high profile Span-Track?

UNEX’s high profile Span-Track was the first full-width roller track in the industry. Span-Track made its debut in 1992 and revolutionized the carton flow industry. High profile Span-Track increases efficiency by providing better flow, fewer hang-ups, and greater storage density than the alternatives—plastic wheel rails or other carton flow solutions.

Tags: carton flow, Unex, Video

Posted in Order Picking & Fulfillment|

What’s the Best Pallet Rack for Your Application?

When approaching pallet rack choices, cost, storage density and construction elements all play a role in making a choice. While cost is always a prime concern, be mindful that cost is often tied to storage density. Cheaper pallet rack tends to not have as much storage density as more expensive rack. But before you consider cost, you must decide what applications you will use the pallet rack for.

Tags: gravity flow rack, selective pallet rack, structural, seismic, mobilized

Posted in Pallet & Warehouse Racks|

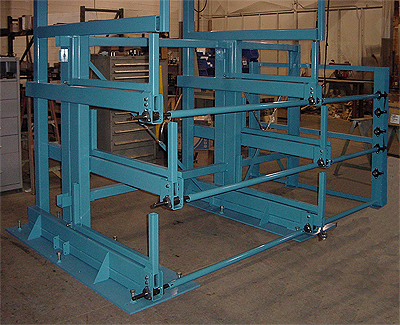

Long Item Storage: Comparing Traditional and Crank-Out Cantilever Racks

If you’ve got conduit, tubing, rebar, pipe or bar stock, you need cantilever rack – period. Get it off the floor, off of standard shelving and pallet rack, and put it somewhere you don’t have to fight with it each time you need some. If you’re really smart, you’ll put it where overhead lift equipment can get to it – because once you get it stored right, you’ll wonder what the heck you were thinking earlier.

Tags: Safety & Ergonomics, cantilever rack, crank out shelving, ergonomic, heavy duty cantilever rack

Posted in Pallet & Warehouse Racks|

5 Common Pallet Rack Mistakes

When it comes to warehouse storage, pallet racks provide an optimal, easy-to-maintain solution. They’re the most common way of storing pallet loads in the world, and they’re used in the vast majority of warehouses, manufacturing facilities, commercial operations and even retail stores. Whether you’re dealing with selective, pushback, drive-in or other types of racks, the issues are frequently similar.

Safe pallet rack operation involves understanding how to properly use racks; an otherwise safe rack can become dangerous and expensive if used incorrectly. Here are 5 common mistakes people make with pallet racks—and what you can do to ensure you don’t make any of them in your warehouse.

Tags: Warehouse Management, pallet racks

Posted in Pallet & Warehouse Racks|

More is More: Estimating Pallet Rack Upright Capacities

There are two types of pallet rack capacity to take into account: beam and upright. Getting those capacities right is a critical factor in safe, efficient rack operations, so understanding why they are very different numbers is important.

Posted in Pallet & Warehouse Racks|

A Guide To Pallet Rack Load Types

Is this an unevenly distributed load? Concentrated load?

Line load? Point load? Load of something really heavy?

We have stressed this before: rack loads aren’t just simple weight vs. structure. The dimensions, shape, and size/density of the load as it sits on storage racks is absolutely critical to safe, effective warehouse storage. Our friends at Nashville Wire recently released an excellent piece that helps define the load types and how you can avoid incorrect or unsafe rack loading.

Tags: Pallet Rack, industrial storage, Safety & Ergonomics, storage rack

Posted in Pallet & Warehouse Racks|

How To Get Your Pallet Rack Height-to-Depth Ratio Right

When designing pallet racks, people tend to pay attention to the easy parts. Beam capacity is straight math; the capacity of a pair of beams, so long as the load is evenly distributed, the load properly positioned, and the safety clips are installed, is a reliable number. Upright frame capacities are a more complex, as they rely on vertical spacing between levels. Get these factors right, and typically it doesn’t take an engineer to design a safe and reliable rack system.

Posted in Pallet & Warehouse Racks|

Key Considerations for Warehouse Rack Aisle Widths

Forklift aisle widths are typically set when pallet racking is installed. In many cases, such as narrow aisle projects, these spaces are critically important. Typically, warehouse managers don’t attempt to lay out these types of storage facilities. But for reach truck, selective rack applications, these aisle sizes are often “eye balled,” or given a 12′ width no matter what type of forklift is using the aisles. If you are laying out a facility, what criteria should you use for rack aisle width?

Posted in Space Optimization & Planning|

What Causes Pallet Rack Collapses?

We have all seen the spectacular (sometimes humorous), but often horrifying videos of rack collapses. They’re all over YouTube. But what really happens to cause these dangerous incidents?

Tags: industrial safety, warehouse racking

Posted in Pallet & Warehouse Racks|