In recent years, many vendors have created products to help increase pedestrian safety in warehouses, factories, and other areas where forklifts operate. This is no wonder: accidents in this area are far too frequent, and often very devastating or even fatal. Because Cisco-Eagle provides such solutions, we have been asked about the compliance of these products to industry standards, such as the AIAG’s Pedestrian & Vehicle Safety Guidelines.

Read the rest of this entry »

Tags: Material Handling, industrial safety, warehouse safety, forklift safety

Posted in Forklift - Pedestrian Safety|

We have all seen the spectacular (sometimes humorous), but often horrifying videos of rack collapses. They’re all over YouTube. But what really happens to cause these dangerous incidents?

Read the rest of this entry »

Tags: industrial safety, warehouse racking

Posted in Pallet & Warehouse Racks|

In a recent blog post, Auburn professor Dr. Kevin Gue, one of the bright minds in the industry when it comes to the business of industrial distribution and plant operations, reflected on the reaction to his ProMat 2013 talk on “Designing a Worker-Centric Facility”. Gue has smart points about the relationship between safety and ROI – and how you can deal with those issues.

Read the rest of this entry »

Tags: industrial safety, ergonomics, ROI

Posted in Safety & Ergonomics|

Take a look at your conveyor – do you think it’s safe? Are there sufficient guardrails? Are operators wearing loose clothing? Are visitors allowed near running lines? Because conveyor seems safe at a glance, it’s an often-overlooked hazard. Used correctly, of course, it is a safe way to increase productivity.

Read the rest of this entry »

Tags: Conveyor, OSHA, industrial safety, warehouse safety, conveyor safety

Posted in Conveyor Optimization|

In an industrial environment, intersections can be dangerous. With fast-moving workers who are busy and probably distracted, and fast-moving forklifts that may have loads elevated that can obstruct the driver’s view, corners, ends of rack rows, and intersections can be the cause of many accidents. Whether it’s a worker walking and carrying a load, or a forklift on its way to the next pick, the chances of collisions, injuries, and damages are greater at intersections than most anywhere else. What are your options when it comes to making your intersections safer?

Read the rest of this entry »

Tags: AisleCop, sensors, ZoneSafe, OSHA, industrial safety, warehouse safety, forklifts

Posted in Forklift - Pedestrian Safety|

In a fast-paced distribution center, there is plenty of forklift traffic, moving conveyors, packing machines, carousels, and dock doors. Same with manufacturing; you have all kinds of production machinery, welding (human and robotic), and heavy material being handled, stacked, or processed, along with the forklifts and other handling equipment. It’s hard enough to keep your own people – the ones who should know the lay of the land – safe in these environments. But what about visitors who haven’t had the benefit of your safety training and the situational awareness that your employees develop over time?

Read the rest of this entry »

Tags: warehousing, Manufacturing, industrial safety, pallet racking, Safety & Ergonomics

Posted in Safety & Ergonomics|

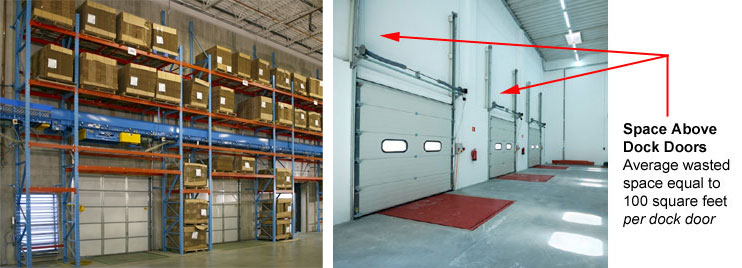

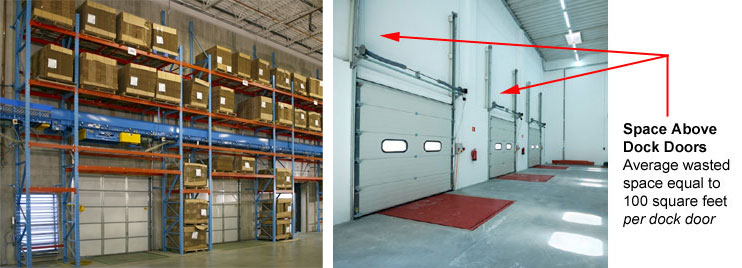

Next time you’re standing there wondering where you’re going to put an inbound shipment while your dock is stacked with empty pallets, look at those doors (or at the void above them) — the copious space between the top of the doors and the ceiling is unused. Multiply each door by that amount of space, and in many operations, we’re talking serious amounts of unused square footage.

The easy solution: find a use for it with over-dock-door storage. You can’t really rack heavy stuff up there without some significant structure. The best thing to consider is empty pallets, which take up a ton of room and are relatively lightweight. And usually, they’re all over the floor and always in your way. Empty pallets clutter up the shipping & receiving docks or can take up positions in your racks that would be better suited to full pallets of finished goods or incoming shipments.

Read the rest of this entry »

Tags: pallets, warehousing, Material Handling, Pallet Rack, space savings, industrial safety, dock doors

Posted in Space Optimization & Planning|

There isn’t enough room at your average industrial workstation. In fact, many order pickers, packers, shippers, and other professionals might tell you that you could have a 10′ long workbench, and they’d still be squeezed for space. In a busy operation, it’s a constant battle between availability of materials and space for doing the actual work. So what’s the solution? A larger workbench top?

Read the rest of this entry »

Tags: workstations, ergonomics, workbenches, order fulfillment, industrial safety

Posted in Storage, Organization & Workstations|

There are many issues of productivity and safety that are stressed as the heat rises. As temperatures start to rise, it gets particularly hot in industrial facilities, warehouses, shops, and distribution centers where air conditioning isn’t always present, extremely costly, or very effective. Experts say that employee productivity increases when ambient temperatures are comfortable and plummets when they aren’t. Error rates climb and safety is compromised as workers fight through hot, sweaty conditions. Here are some ways you can go about combating the rigors of summer.

Read the rest of this entry »

Tags: Material Handling, industrial safety, heat stress, heat exhaustion, industrial fans, climate control, fans, Conveyor, warehousing

Posted in Safety & Ergonomics|

Read our customer reviews