Some conveyors are specifically modular. They’re meant to be moved around, plugged in and reconfigured. But most conveyors are semi-permanent, and occupy space for extended periods of time. When you want to re-use existing conveyors in new roles, move all or part of a system between facilities, or just reconfigure an area using the equipment you already have, you can save money, but there are some things to know to help ensure everything works smoothly.

Moving, Reusing and Reconfiguring Conveyor Systems

Tags: ROI

Posted in Conveyor Optimization|

How to Convey Poly Bags & Envelopes

The shift from traditional retail to e-commerce is accelerating, and with that growth there are both challenges and opportunities for order fulfillment operations. Companies that spent decades perfecting retail distribution (large, bulk orders to a network of stores) are shifting toward direct-to-consumer shipments that are orders of magnitude more difficult to manage.

Among other things, this means that e-commerce companies must focus on optimal packaging.

Tags: Order Picking & Fulfillment, ecommerce, order fulfillment

Posted in Conveyor Optimization|

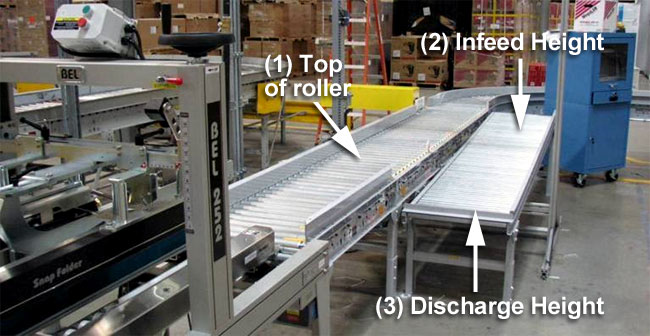

How to Measure Conveyors

This is part three of our guide to measuring material handling equipment. When you want to lay out a conveyor, there are methods to measurement that can ensure the equipment fits where you need it to, interfaces with machinery, matches work station heights, and other critical measures.

Tags: Space Optimization

Posted in Conveyor Optimization|

A Video Guide to Extendable Conveyors

Warehouses have always had problems with the point in their material handling system where docks or shipping areas meet the production line. For lack of a better word, these are awkward areas where it’s difficult to handle product in that dead zone between the end of a material handling system and truck trailers.

Read the rest of this entry »

Tags: Video

Posted in Conveyor Optimization|

A Guide for Conveyor Proposals & Specifications

Conveyors are a critical part of warehousing operations, but there are many options, providers and variables. To help clear that up, we have created a quick download for your use. Let’s break down what you need to know beyond the obvious.

Tags: ROI

Posted in Conveyor Optimization|

How to Set Overhead Conveyor Clearances

OSHA’s conveyor guidelines focus on guardrails and emergency stops, but when it comes to conveyor safety, the story hardly ends there. One neglected aspect is in areas where people may pass under suspended or overhead conveyors. Here are some best practices for those situations.

Posted in Conveyor Optimization|

A Guide to Conveyor Rollers “Set Low”

When conveyor rollers are set low, you gain several advantages vs. rollers set high. When you do this, your conveyor has several advantages.

Tags: rollers, Accumulation Systems, conveyor design

Posted in Conveyor Optimization|

The Ergonomics of Flexible Conveyors

As we have covered previously, conveyors contribute to ergonomics in material handling operations by reducing repetitive lifts, twists, reaching and materials movement that may have been done by hand without them. Eliminating manual lifting and carrying reduces the chances for painful, expensive musculoskeletal injuries. It’s not about the once-in-a-while lift/carry but the same, repetitive motions over and over.

It’s important that your conveyor is configured correctly to make this work. Read the rest of this entry »

Tags: ergonomics, worker safety, loading docks

Posted in Conveyor Optimization|

How to Use Conveyors to Increase Warehouse Ergonomics

Conveyors are ergonomic equipment by nature. They reduce manual lifting, pushing, pulling and stretching by delivering product to workers and reducing the stress of carrying or pushing it manually. Whether in a large integrated system or a spur of gravity, conveyors are great for reducing the number of people who engage in potentially dangerous activities that could cause musculoskeletal issues. Let’s dive into ways to be sure your conveyors are contributing to an ergonomic operation.

Tags: ergonomics, Safety & Ergonomics

Posted in Conveyor Optimization|

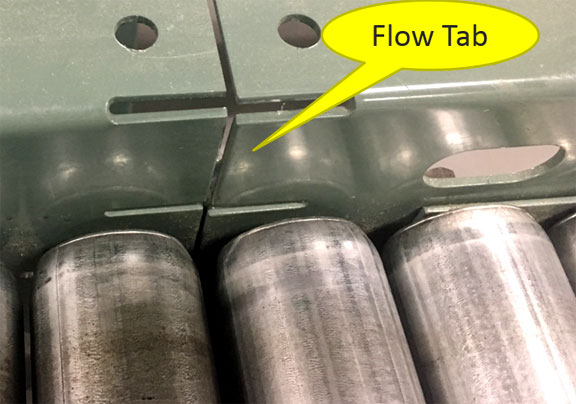

Gravity Conveyors and Product Flow

Install Gravity conveyors on declines so that the infeed side sits higher than the end of the line for smooth product flow. This is one of the easiest ways to move products quickly and economically. How can you set up your gravity conveyor for optimal product flow?

Tags: Roller Conveyors, shipping docks, skate wheel conveyors

Posted in Conveyor Optimization|