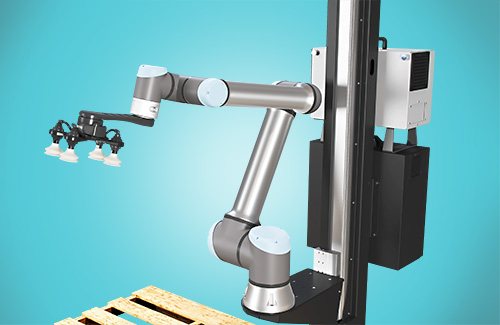

One of the most exciting things about today’s automation is that it’s becoming increasingly specialized; like eating from a buffet, you can choose what you want. That’s the idea behind cobot palletizers that zero in on a specific target: lighter weight, end-of-line carton palletizing that used to take high six figures and months of implementation time. The critical part of any palletizing project, of course, is the end effector.