Every company that operates forklifts struggles with pedestrian safety problems. The issues are well-documented; forklifts are often the most problematic safety machinery in any operation that utilizes them.

Every company that operates forklifts struggles with pedestrian safety problems. The issues are well-documented; forklifts are often the most problematic safety machinery in any operation that utilizes them.

Tags: plant safety, forklift safety, forklift

Posted in Forklift - Pedestrian Safety|

Above: James Murphy moderates a panel discussion on automation return-on-investment

Cisco-Eagle’s Bryan Gauger joined Mitch Smith of Hytrol and Nils Hart of Muratec for a Warehousing Education and Research Council panel on automation projects return-on-investment. The discussion revolved around ROI factors ranging from labor to safety. Because labor and money are both tight, justifying capital expenditures is more important than ever. Here are the panel’s thoughts on critical ROI issues:

Tags: ROI, Video

Posted in Automation, Labor & Efficiency|

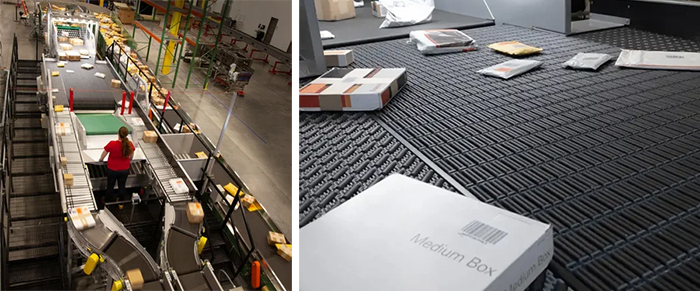

Singulation separates and single-lines cartons and other loads into lines as they move on a conveyor. Bulk and parcel applications frequently require singulation. Conveyors and control systems use multi-speed belts, dedicated singulators, skewed rollers and side-driven motors to unscramble multiple lines of products into single-file. Think of singulation as the process of organizing cartons or other loads into a single, neat line for future processing.

Singulation is pivotal for in sorting and organizing materials ranging from boxes to fragile electronics to sturdy automotive components on conveyor systems.

Tags: Automation

Posted in Conveyor Optimization|

Creating a culture of safety is a high priority (and always ongoing) in any facility that values its operations. Whether it is safer forklift/pedestrian interactions, ergonomic improvements, or machine protection, every warehouse is constantly working to improve the conditions within its walls.

But what about the area outside, say, in the parking lot? Sure, it’s not a glamorous area, but you want to keep your workers safe and secure there too!

Posted in Safety & Ergonomics|

Warehouses use pallet racks because they maximize storage space, streamline operations, and organize inventory like no other system. We discuss rack safety in depth because it’s so critical for protecting people, property, inventory and facilities. A rack safety fundamental is anchoring: the right anchors, installed correctly, into a subfloor designed for that purpose. Think of the floor-rack connection as the very basis of your rack’s balance and capacity.

Tags: warehousing, storage, Safety & Ergonomics

Posted in Pallet & Warehouse Racks|

While not every facility moves or uses drums for storage, those that do have a necessity to keep them safe. Whether they contain hazardous material or not, the effort to keep barrels upright and from spilling never ends, because who wants lost product or an unsafe work environment?

To ensure your workers keep drums handled correctly, there are multiple solutions available.

Posted in Material Handling|

How should your next automation project be evaluated? In many cases, companies try to replicate a manual processes through automation: if a person once rotated a tote, then picked from it and placed the contents into a container, that’s what the automation does. This kind of solution can provide excellent results, but may not be the optimal solution. What if you began with operational goals in mind that imagine a solution without the manual process?

Tags: ROI, Process Management

Posted in Automation, Labor & Efficiency|

Most every manufacturing or distribution facility builds in storage and handling buffers – and for good reason. Buffers hold product or processes when work flow isn’t balanced. For instance, a conveyor buffer may exist between picking and packing operations. This allows picking to continue even if the packing, quality control or shipping departments are backed up. Buffers maintain balance between functions and ensure continuity.

Tags: order fulfillment, ROI, conveyor design, Space Optimization

Posted in Automation, Labor & Efficiency|

The new age of material handling solutions is bringing many products once unheard of. Whether it’s an automated process designed to ease the burden on employees and improve throughput, or new safety features that increase awareness while removing danger, futuristic improvements are being adopted at an incredible rate.

There are, however, some tried and true methods of ferrying items from one area to another in a facility. Take the pallet dolly….a solution that’s been around forever and stood the test of time (and movement!).

Posted in Material Handling|

Conveyors and Autonomous Mobile Robots (AMRs) are both used in logistics, manufacturing, and warehousing, but have critical differences in terms of functionality, flexibility, and applications. Neither system is inherently superior to the other based on the use case, situation, load and operational goals. When you need to build a product transport system, they can often work in tandem to create the best solution.

Posted in Conveyor Optimization|