A few years ago, I looked out a Chicago hotel room window at the sub-roof of a skyscraper hotel. A long run of pipes and air ducts cut the roof in half, so that anyone who needed to work on it would have to walk a long way around or climb over. Since there were obvious points of maintenance and other equipment on both sides of the obstructions, I’m guessing that maintenance workers were doing exactly that. They needed a crossover, and a roof top isn’t the easiest place to install one, particularly post-construction.

How to Position Crossovers on Rooftops

Tags: Space Optimization

Posted in Safety & Ergonomics|

Crossing Conveyor Lines: The Options

The extensive conveyor lines that snake through many distribution facilities allow operations to transport, buffer and direct loads in a way that takes the best possible advantage of space. These conveyor systems are essentially the core around which a lean, efficient material handling operation is built, but they also create barriers to people moving around the facility since they can block the flow of foot traffic.

Tags: Shoptalk

Posted in Conveyor Optimization|

Crossovers and Work Platforms: The Advantages of Modular

I recently attended training on a crossover and work platform product that continues to impress me for its flexibility and innovative engineering. Because of its modular design, it stands out from fabricated and manufactured products because it can morph and change as your needs change. There are times where a fixed, welded platform is fine, but it has hidden costs. Let’s examine those…

Tags: Perfect A Step, Space Optimization, crossover, work platform, modular, Erect A Step

Posted in Mezzanines & Industrial Platforms|

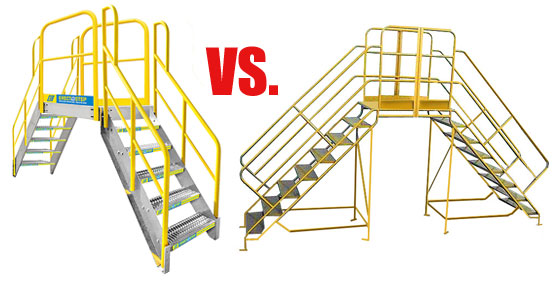

Comparison: Modular vs. Tubular Steel Crossovers

In many operations, things like conveyors or pipe runs or other machinery interrupt the flow of a work floor, and the obvious way to get around it is to erect a crossover. This is commonly done in larger scale conveyor systems with longer lines, but we also do them for other areas where going around the obstacle could take significant time, or where access is limited by other factors. The question is, what type of crossover best fits your needs?

Posted in Warehousing & Distribution|

Am I Wasting Time: is Cross-Docking a Viable Consideration for my Company?

This article is the second in a series of articles on cross docking

In concept and on paper cross docking looks great, but, what about actual implementation? What kind of return do we get on this investment? The short answer is the implementation can be challenging. However, with planning, a committed team of upstream and downstream participants, and pilot programs, it can pay significant benefits.

Cross docking does not have to be complicated. Some, even today, execute cross-docking using human-readable paper documentation as the driver. As mentioned in the original brief, cross docking can cover a wide range of distribution activities. In one door and directly out the other is one approach. Many cross dockers also add value in the brief (hopefully) interval between receiving and shipping. Others send product to a temporary buffer in the interval, in many of these cases an automated system (mini-load, AS/RS, etc.) serves as the buffer.

Tags: Cross Docking, advance shipping notices, dock layout, Supply Chain, cross dock

Posted in Docks & Shipping|

The Easiest Win in Automation: Machine Loading and Unloading

Machine load-unload automation is one of the most profitable and straightforward automation opportunities in both warehouses and factories. It improves productivity in two key ways:

- Reducing labor needs: Repetitive manual loading and unloading is replaced with automation, cutting costs and reducing injury risk.

- Increasing machine uptime: Machines stay productive with predictable cycles, eliminating idle time between parts.

The real payoff is in uptime. When unloading and reloading are automated, a machine rarely waits for an operator. Preparatory work and staging can happen offline, so the next part is always ready. In ideal cases, production rates can increase dramatically without additional equipment investments. Focusing on these key points, where automation can have outsized impact is the key to smarter, better operations. These tend to be low value, but critical processes that should be automated so that labor can be reallocated to more critical functions.

Tags: Automation, Manufacturing

Posted in Automation, Labor & Efficiency|

Insights August 2025: Employee-Ownership & Manufacturing

This month, we discuss strategic warehouse execution system implementations with Savoye–how to scale, how to match real-world processes. Additionally, the impact of employee ownership on manufacturing and its potential as a key to succession for small and mid-sized manufacturers. Also, more on industrial construction and the softening demand for manufactured products.

Read the rest of this entry »

Posted in Industry Insights|

Cisco-Eagle Announces 2025 Core Values Awards

Cisco-Eagle named its inaugural Core Values award winners in June 2025. These are employee-owners who embody our core values–the principles we aspire to. Those values were established over thirty years ago and remain unchanged since. “They are universal and timeless,” said CEO Darein Gandall. Our founder, Warren Gandall, has often said that he wants to treat his suppliers, customers and employees the way he wants to be treated.

Our values reflect that vision, and so do the 2025 winners of these awards.

Posted in ESOP & Company News|

Behind the Gates: A Conversation with Markus Green on AisleCop Gen5

When pedestrian safety meets forklift traffic, there’s no room for error. That’s where AisleCop® comes in. And now, with the launch of Gen5, Cisco-Eagle has made it faster, easier, and more scalable to deploy than ever before.

We sat down with Markus Green, head of our Safety Automation department, to talk about what’s new, why Gen5 was developed, and how it’s helping safety managers and operations teams move faster.

Posted in Forklift - Pedestrian Safety|

Best Practices for Loading & Unloading Pallet Conveyors with Forklifts

Loading and unloading pallet conveyors with forklifts is an everyday, all-day task.

Done right, it’s fast and efficient. Done wrong, product damage, collisions, injuries, and workflow bottlenecks happen. I’ve seen it in dozens of warehouses, even in highly automated operations, and most of them tend to bridge the shipping dock and the end conveyor lines with forklifts (these days, AGVs and AMRs often do this work). Pallets are large, heavy and in motion when they’re transported on conveyors. That combination of size, pressure and movement can result in damage or injuries when not properly controlled.

Tags: conveyor safety, forklifts

Posted in Conveyor Optimization|