We all know what happens to tooling and die when it’s stored haphazardly. Bumped and scratched, a chip here, a nick there, and suddenly your machining just isn’t what it used to be. The quality has slipped, maybe more products are being returned, there’s an increase in customer complaints. It’s too valuable and too expensive to risk. What are your options?

Tool & Die Storage Done Right

Tags: sheet metal storage, tool & die rack, tooling, machining, CNC, lathe, cutter

Posted in Pallet & Warehouse Racks|

Warehouse Safety Sensor Systems: Which Fits Your Needs?

Safety is a major issue in most industrial environments – especially those where industrial traffic like forklifts, AGV’s and other vehicles mingle with workers on foot. There are just too many ways people can get hurt; too many chances for things to suddenly go wrong. That’s why including some automated safety sensor systems in a facility can make a life and death difference on a day-to-day basis.

Tags: safety sensors, motion detection, infrared sensor, industrial safety, forklift safety, traffic management, safety systems

Posted in Forklift - Pedestrian Safety|

Video: 24-Volt Roller Conveyors “Simplify Everything”

When you look at your next live roller conveyor system, it’s smart to look at new advances. Hytrol’s e24 conveyor is one of the most important new product introductions in many years. It’s difficult to understate how this conveyor can enhance operations, but here is a quick summary of the advantages.

Tags: Hytrol, conveyor systems, roller conveying systems, e24

Posted in Conveyor Optimization|

Order Picking: Optimizing and Storing Slow Movers

The focus when it comes to order picking is usually (and justifiably) on the fastest-moving product. You slot your warehouse for fast movers. You pareto-focus on the 20% of the product that generates 80% of the business, as you should. But it’s also useful to consider the slow-moving inventory and pick locations. Simply putting the slowest movers in the least accessible area may make them consume more order picking time and storage space than necessary.

Tags: order fulfillment, Industrial Shelving, carton flow racks

Posted in Order Picking & Fulfillment|

5 Manufacturing Challenges (or are they Opportunities?)

U.S. manufacturing is at a crossroads. After decades of decline, there are signs of a renaissance, with the chance to re-shore more and more manufacturing capacity every year. Some of this is driven by the natural gas energy boom, and the cost of shipping product in vs. making it in America. You also see more companies returning capacity due to the fact that offshoring didn’t always live up to its cost cutting premise. Whatever the reason, American manufacturing now faces the reality of growth, with the challenges and opportunities that brings.

Posted in Manufacturing|

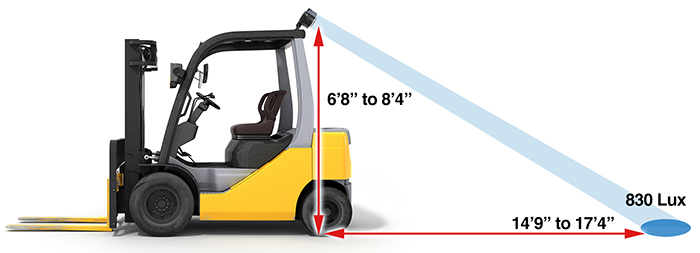

Configuring a Forklift Warning Light

When it comes to pedestrian safety in warehouses, the problem can be plain old attention span

People who aren’t paying attention are at the most risk, particularly those who walk near and around forklifts. People don’t pay attention because they’re busy, worried about deadlines. Or they’re absorbed in their smart phone, or in a conversation with someone. The reasons vary, but when forklifts are involved, the results can be deadly.

Posted in Forklift - Pedestrian Safety|

A Quick Guide to Order Picking Methods & Productivity

When you work on order picking strategies, knowing the metrics for picking rates may be helpful. Labor productivity is the key to any warehousing or order picking operation, since labor tends to be the largest single cost factor in these operations. It’s critical to understand production rates for processes that absorb labor hours, energy, money, and time.

Posted in Order Picking & Fulfillment|

Tactics to Reduce Small Parts Order Picking Errors

Small parts are more difficult to count, measure and handle. They tend to cause more errors than case picking or larger component orders. If you are having errors, you should try to define the causes — and the suspects abound. Can you find out what’s causing the errors? Once you do, what happens next? Here are some common causes and solutions to this issue.

Tags: Order Picking & Fulfillment, 5S principles, error reduction, lean warehousing

Posted in Order Picking & Fulfillment|

Industrial Pedestrian Safety Automation & Industry Guidelines

In recent years, many vendors have created products to help increase pedestrian safety in warehouses, factories, and other areas where forklifts operate. This is no wonder: accidents in this area are far too frequent, and often very devastating or even fatal. Because Cisco-Eagle provides such solutions, we have been asked about the compliance of these products to industry standards, such as the AIAG’s Pedestrian & Vehicle Safety Guidelines.

Tags: Material Handling, industrial safety, warehouse safety, forklift safety

Posted in Forklift - Pedestrian Safety|

What Is the 5S Process: 11 Visualizations That Explain It Best

5S is a philosophy that hones in on effective workplace organization and standardized work procedures. The concept is based off 5 Japanese words that begin with “S”: seiri, seiton, seiso, seiketsu and shitsuke. When translated to English, there are five primary 5S phases: sorting, setting in order, systematic cleaning, standardizing and sustaining. Or in shortened terms: Sort, Straighten, Shine, Standardize and Sustain. When implemented correctly, 5S reduces waste and increases efficiency and overall work quality.

The 5S Philosophy is best captured in visualization, since its process can be complex, even if it is boiled down into five simple terms. Here are seven creative visualizations we found describing 5S, from organizations and vendors across the world wide web.

Read the rest of this entry »

Posted in Manufacturing|