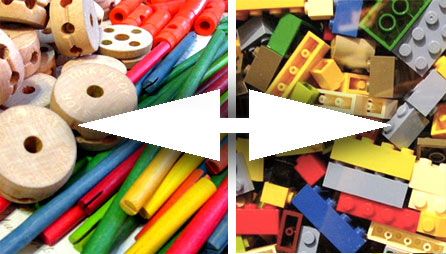

Merging two formerly separate industrial operations can be more difficult, expensive, and time consuming than creating an entirely new plant. After all, even in the best of scenarios, it’s almost always easier to start with a blank slate. But in these days of consolidations and cost cutting, this can happen to almost any company. Planning and open communications is the key in general, but there are specific issues you should be aware of.

What are some pitfalls, and how can you avoid them?